PAGE 9

WS1TC & WS1.25 TC Manual

Page 13

6

2

4b

4a

5

1

3

7

8

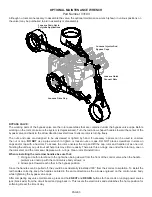

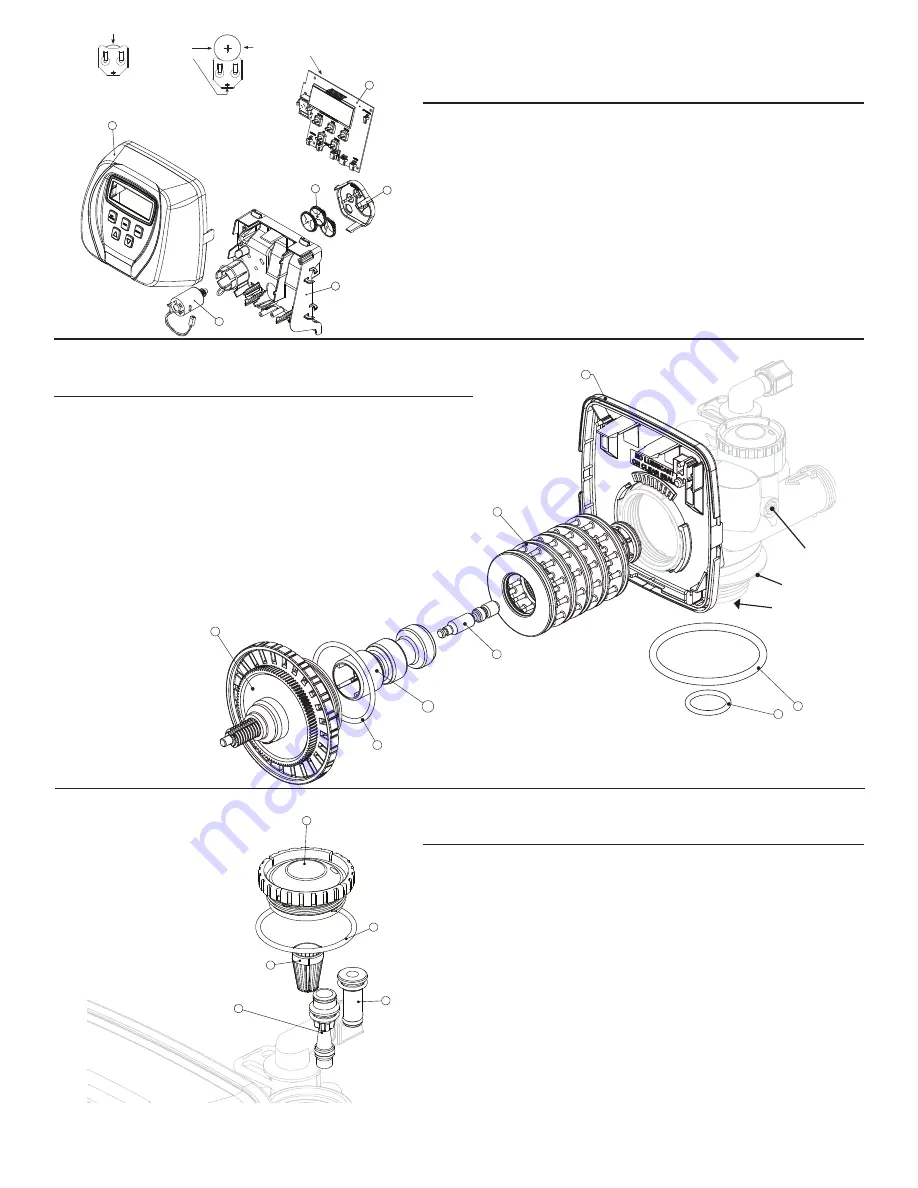

WS1TC Drive Cap Assembly, Down ow Piston, Regenerant Piston and Spacer Stack Assembly

Drawing No.

Order No.

Description

Quantity

1

V3005

WS1 Spacer Stack Assembly

1

2

V3004

Drive Cap ASY

1

3

V3178

WS1 Drive Back Plate

1

4

V3011

WS1 Piston Down ow ASY

1

5

V3174

WS1 Regenerant Piston

1

6

V3135

O-ring 228

1

7

V3180

O-ring 337

1

8

V3105

O-ring 215 (Distributer Tube)

1

Not Shown

V3001

WS1 Body ASY Down ow

1

V3001-02

WS1 Mixing Valve Body ASY

Note: The regenerant piston is not used in backwash only applications.

Black Plug

4

Grey plug on all

WS1.25 bodies

*Grey Ring

*Grey Distributor

O-ring retainer

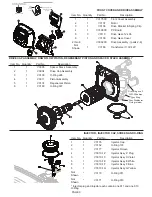

FRONT COVER AND DRIVE ASSEMBLY

Item No.

Quantity

Part No.

Description

1

1

V3175CC

Front Cover Assembly

2

1

V3107

Motor

3

1

V3106

Drive Bracket & Spring Clip

4

1

V3108CC

PC Board

5

3

V3110

Drive Gear 12 x 36

6

1

V3109

Drive Gear Cover

2 thru 6

V3002CC

Drive Assembly - (parts 2-6)

Not

Shown

1

V3186

Transformer 110V-12V

DRIVE CAP ASSEMBLY, DOWNFLOW PISTON, REGENERANT PISTON AND SPACER STACK ASSEMBLY

Item No.

Quantity

Part No.

Description

1

1

V3005

Spacer Stack Assembly

2

1

V3004

Drive Cap Assembly

3

1

V3135

O-Ring 228

4

1

V3011

Piston Assembly

5

1

V3174

Regenerant Piston

6

1

V3180

O-Ring 337

INJECTOR, INJECTOR CAP, SCREEN AND O-RING

Item No.

Quantity

Part No.

Description

1

1

V3176

Injector Cap

2

1

V3152

O-Ring 135

3

1

V3177

Injector Screen

4

1

V3010-1Z

Injector Assy Z Plug

5

1

V3010-1C

Injector Assy C Violet

5

1

V3010-1E

Injector Assy E White

5

1

V3010-1F

Injector Assy F Blue

5

1

V3010-1G

Injector Assy G Yellow

Not

Shown

*

V3170

O-Ring 011

Not

Shown

*

V3171

O-Ring 013

* Injector plug and injector each contain one 011 and one 013

O-Ring

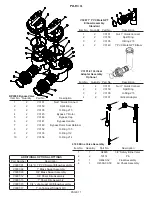

WS1 & WS1.25 Drawings & Service Manual

Page 5

Injector Cap, Injector Screen, Injector, Plug and O-Ring

1

2

3

4

5

Drawing No.

Order No.

Description

Quantity

1

V3176

INJECTOR CAP

1

2

V3152

O-RING 135

1

3

V3177-01

INJECTOR SCREEN CAGE

1

4

V3010-1Z

WS1 INJECTOR ASY Z PLUG

1

5

V3010-1A

WS1 INJECTOR ASY A BLACK

1

V3010-1B

WS1 INJECTOR ASY B BROWN

V3010-1C

WS1 INJECTOR ASY C VIOLET

V3010-1D

WS1 INJECTOR ASY D RED

V3010-1E

WS1 INJECTOR ASY E WHITE

V3010-1F

WS1 INJECTOR ASY F BLUE

V3010-1G

WS1 INJECTOR ASY G YELLOW

V3010-1H

WS1 INJECTOR ASY H GREEN

V3010-1I

WS1 INJECTOR ASY I ORANGE

V3010-1J

WS1 INJECTOR ASY J LIGHT BLUE

V3010-1K

WS1 INJECTOR ASY K LIGHT

GREEN

Not Shown

V3170

O-RING 011

*

Not Shown

V3171

O-RING 013

*

* The injector plug and the injector each contain one 011 (lower) and 013 (upper) o-ring.

Note: For up

ow position, injector is located in the up hole and injector plug is in the

other hole. WS1 up

ow bodies are identi

ed by having the DN marking removed.

Up

ow option is not applicable to EE, EI, or TC control valves.

For a

lter that only backwashes, injector plugs are located in both holes.

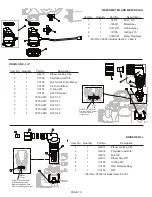

CC Man u al

Page 3

1

2

3

5

6

Battery replacement is

3 volt lithium coin cell

type 2032.

Correct

Battery

Orienta-

tion

Battery Fully Seated

When replacing the battery, align

positives and push down to fully seat.

4

AC Adapter

U.S.

International

Supply Voltage

120 V AC

230V AC

Supply Frequency

60 Hz

50 Hz

Output Voltage

12 V AC

12 V AC

Output Current

500 mA

500 mA

CC Front Cover and Drive Assembly

Drawing No.

Order No.

Description

Quantity

1

V3175CC-01

WS1CC FRONT COVER ASSEMBLY

1

2

V3107-01

WS1 MOTOR

1

3

V3106-01

WS1 DRIVE BRACKET & SPRING CLIP

1

4

V3108CC-02BOARD*

WS1 THRU2L CC PCBRD ALT REPLACE

1

V3108CC-03BOARD*

WS1 THRU2L/2 CC PCB REPLACE

5

V3110

WS1 DRIVE REDUCING GEAR 12X36

3

6

V3109

WS1 DRIVE GEAR COVER

1

Not Shown

V3186

WS1 AC ADAPTER 110V-12V

1

V3186EU

WS1 AC ADAPTER 220-240V-12V EU

V3186UK

WS1 AC ADAPTER 220-240V-12V UK

V3186-01

WS1 AC ADAPTER CORD ONLY

Not Shown

V3178

WS1 DRIVE BACKPLATE

1

*Note: The V3108CC-02BOARD can be used on all valves except for WS2 valves.