PAGE 12

Drop will flash while water

is being treated.

NEXT

NEXT

Contact Screen

NEXT

GENERAL OPERATION

User Displays

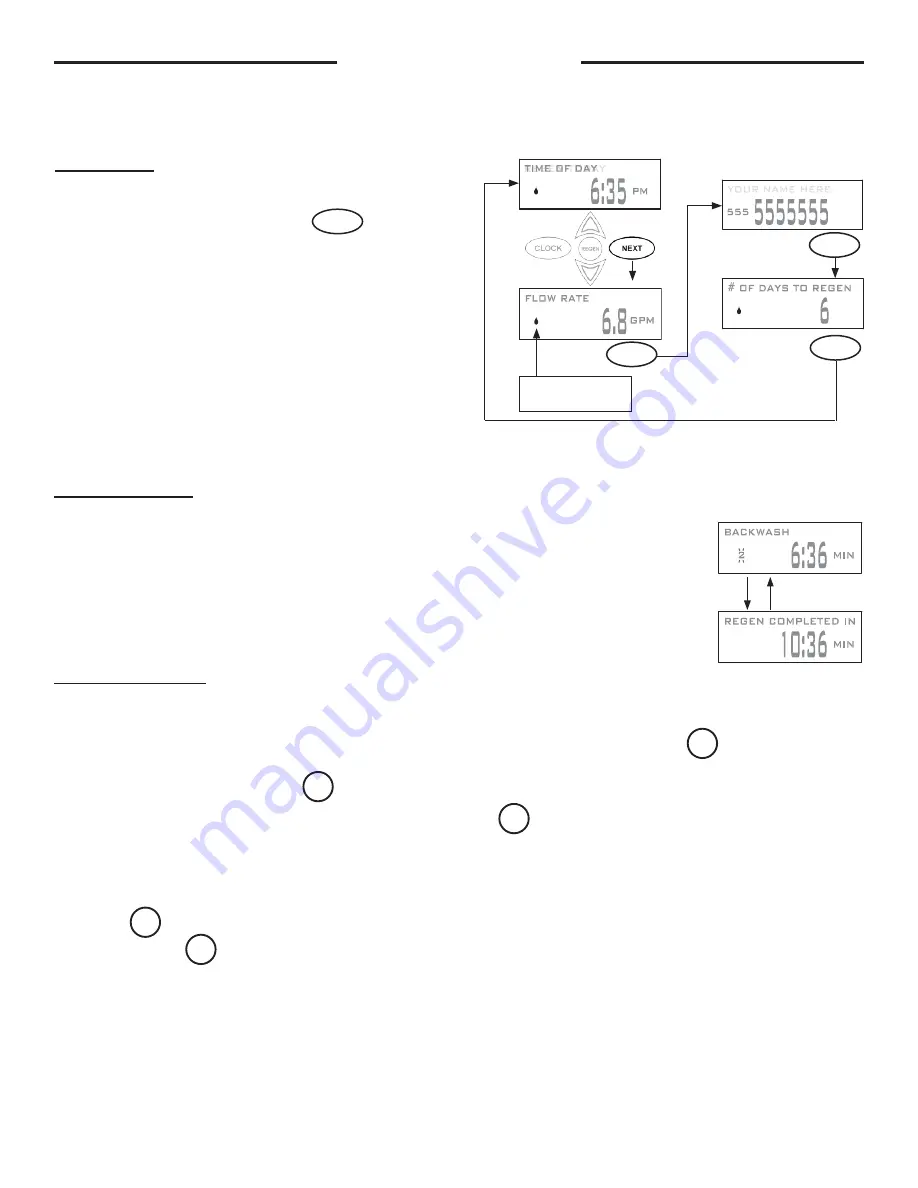

When the system is in normal service mode, display

illumination is SOLID BLUE and one of up to four available

User Displays will be shown. Pressing

NEXT

will alternate

between the following displays:

• Current time of day

• Treated water flow rate

Utilizing the control valve’s built-in water meter,

a water drop flashes on the display when water

is being treated (i.e. water is flowing through the

system).

• Service contact name and phone number (if entered)

• Remaining days to regeneration (if Day Override is

programmed)

Note: As an energy saving feature, the control will automatically turn off all SOLID BLUE or SOLID GREEN

display illumination and keypad illumination after about 5 minutes of the last keypad button push. Any further

keypad touch will cause the re-illumination of the display and keypad, and re-activate keypad control.

DISPLAYS

ALTERNATE

BEING VIEWED

If the system has called for a backwash that will occur at the preset time of backwash, the words REGEN

TODAY will alternate with the header on the display.

Regeneration Mode

Typically a system is set to regenerate at a time of low water usage. An example of a time with low water usage is when

a household is asleep. If there is a demand for water when the system is regenerating, untreated

water will be used. Factory preset delayed regeneration time: 12:00 AM (midnight).

When the system begins to regenerate, the display will change to SOLID GREEN when

illuminated, and include information about the step of the regeneration process and the time

remaining for that step to be completed. The current cycle display will alternate with the regen

time remaining screen. The system runs through the steps automatically and will reset itself to

provide treated water when the regeneration has been completed.

Manual Regeneration

Sometimes there is a need to regenerate the system sooner than when the system calls for it, usually referred to as

manual regeneration. There may be a period of heavy water usage because of guests or a heavy laundry day.

To initiate a manual regeneration

at the preset delayed regeneration time

, press and release

REGEN

. The words “REGEN

TODAY” will periodically be shown on the display to indicate that the system will regenerate at the preset delayed

regeneration time. If you pressed the

REGEN

button in error, pressing the button again will cancel the request.

To initiate a manual regeneration

immediately

, press and hold the

REGEN

button for three seconds. The system will begin to

regenerate immediately. The request cannot be cancelled.

Sometimes it is desirable to have the valve initiate and complete two regenerations within 24 hours and then return to the

preset regeneration procedure. To do a double regeneration:

1. Press the

REGEN

button once. REGEN TODAY will flash on the display.

2. Press and hold the

REGEN

button for three seconds until the valve regeneration initiates.

Once the valve has completed the immediate regeneration, the valve will regenerate one more time at the preset regen

-

eration time.

Summary of Contents for 7-LXDAN-1B

Page 38: ...PAGE 38...

Page 39: ...PAGE 39...