PAGE 7

Do not add salt to the brine tank yet. Do not plug the transformer into the receptacle yet. Make sure inlet and outlet valves are to their

closed positions. If using optional bypass, place in bypass position. Turn on main water supply. Open a cold water faucet. This will

clear the line of any debris (solder, pipe dope, etc.) that may be in the line. Let water run at faucet for a couple minutes, or until clear.

SLOWLY

turn the bypass to

NORMAL OPERATION MODE

(figure 1)

and allow the softener to fill with water. When water is once

again seen at the opened cold water faucet, turn off water faucet and place the bypass valve in

BYPASS OPERATION

(figure 2)

Manually add 1 ½ gallons of water to the brine tank. Now plug the transformer into a 120 volt receptacle (be certain the receptacle is

uninterrupted). Within 5 seconds the control display and buttons will illuminate and the time of day screen will appear.

•

Press and hold the

REGEN

button for approximately 5 seconds until the motor starts.

•

Wait until display reads

FILL

and numbers start counting down.

•

Momentarily press

REGEN

again. Valve is now in the

SOFTENING

position.

•

Momentarily press

REGEN

again. Valve is now in the

BACKWASH

position.

•

Momentarily press

REGEN

again. Valve is now in the

REGENERANT DRAW

position.

•

Momentarily press

REGEN

again. Valve is now in the

AIR RELEASE

position.

•

Momentarily press

REGEN

again. Valve is now in the second

BACKWASH

position.

If using optional bypass

SLOWLY

turn bypass valve to

DIAGNOSTIC

position (

See figure 3 on page 4

) or slowly open inlet valve to

allow water to slowly enter softener.

When water is flowing steadily to drain without the presence of air, momentarily press

REGEN

again. Display will read

RINSE

. Open the

outlet valve of the softener, or if using optional bypass place to

NORMAL OPERATION MODE

(

see figure 1 on page 4

). Allow control

to finish the

RINSE

cycle. Allow the control to automatically advance to the

SOFTENING

position. Now load the brine tank with salt.

Solar Salt is recommended. The brine tank salt level should be checked every couple of weeks to determine salt usage. Keeping the

brine tank salt level at least 1/2 full is recommended.

SANITIZING

:

Use 2 oz. of 5 ¼% unscented household chlorine bleach for each cubic foot of resin. Pour bleach directly into the 4”

diameter white brine well located inside the brine tank. Press and hold the

REGEN

for 5 - 6 seconds until the motor starts running. Allow

system to complete the regeneration automatically. Check for other local and state codes which may also specify sanitation methods.

Note: The first step of the regeneration process is to fill the brine tank with the proper amount of water. The brine tank will

only have a very slight amount of water in it after the regeneration cycles are completed.

PLACING SOFTENER INTO SERVICE

GENERAL OPERATION

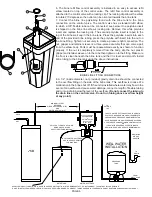

WATER SOFTENER

PRESSURE

TANK

BYPASS PLUMBING

RECOMMENDED

IF

OPTIONAL BP2000

BYPASS VALVE

IS NOT USED.

BRINE TANK

FROM

WELL PUMP

MINIMUM 10 FEET

BETWEEN

WATER SOFTENER OUTLET

AND

WATER HEATER INLET

WATER SOFTENER

BYPASS PLUMBING

RECOMMENDED

IF

OPTIONAL BP2000

BYPASS VALVE

IS NOT USED.

TO

DRAIN

TO

OUTSIDE

TAP

BRINE TANK

WATER

HEATER

DRAIN LINE

AIR GAP

ADAPTER

FROM

WATER MAIN

COLD

HOT

MINIMUM 10 FEET

BETWEEN

WATER SOFTENER OUTLET

AND

WATER HEATER INLET

LOCATE WATER SOFTENER

AS CLOSE AS POSSIBLE

TO BRINE TANK.

A SIX FOOT LENGTH OF 3/8" O.D.

BRINE LINE POLYTUBE

SUPPLIED WITH BRINE TANK.

OVERFLOW GRAVITY DRAIN - ONLY USED IN CASE OF MALFUNCTION IN THE BRINE SHUTOFF. DO NOT CONNECT TO CONTROL VALVE DRAIN LINE.

IF UNIT IS INSTALLED WHERE OVERFLOW COULD CAUSE WATER DAMAGE, CONNECT TUBING AND RUN TO FLOOR DRAIN. DO NOT RUN TUBING ABOVE OVERFLOW HEIGHT.

WELL WATER

INSTALLATION

CITY WATER

INSTALLATION

WATER

METER

TO

DRAIN

TO

OUTSIDE

TAP

WATER

HEATER

DRAIN LINE

AIR GAP

ADAPTER

COLD

HOT

LOCATE WATER SOFTENER

AS CLOSE AS POSSIBLE

TO BRINE TANK.

A SIX FOOT LENGTH OF 3/8" O.D.

BRINE LINE POLYTUBE

SUPPLIED WITH BRINE TANK.

LOCATE WATER SOFTENER CLOSE TO A DRAIN.

AVOID OVERHEAD DRAIN LINES IF POSSIBLE TO

PREVENT BACK PRESSURE ON BRINE INJECTOR.

IF OVERHEAD DRAIN LINE IS USED AND EXCEEDS

5 FEET ABOVE CONNECTION ON CONTROL VALVE

OR

IF DRAIN LINE EXCEEDS 20 FEET IN LENGTH,

DRAIN LINE PIPE SIZE SHOULD BE MINIMUM 3/4".

OVERFLOW GRAVITY DRAIN - ONLY USED IN CASE OF MALFUNCTION IN THE BRINE SHUTOFF. DO NOT CONNECT TO CONTROL VALVE DRAIN LINE.

IF UNIT IS INSTALLED WHERE OVERFLOW COULD CAUSE WATER DAMAGE, CONNECT TUBING AND RUN TO FLOOR DRAIN. DO NOT RUN TUBING ABOVE OVERFLOW HEIGHT.

LOCATE WATER SOFTENER CLOSE TO A DRAIN.

AVOID OVERHEAD DRAIN LINES IF POSSIBLE TO

PREVENT BACK PRESSURE ON BRINE INJECTOR.

IF OVERHEAD DRAIN LINE IS USED AND EXCEEDS

5 FEET ABOVE CONNECTION ON CONTROL VALVE

OR

IF DRAIN LINE EXCEEDS 20 FEET IN LENGTH,

DRAIN LINE PIPE SIZE SHOULD BE MINIMUM 3/4".

Click to buy NOW!

PD

F-XCHANGE

w

ww

.docu-track.c

om

Click to buy NOW!

PD

F-XCHANGE

w

ww

.docu-track.c

om

User Displays

When the system is in normal service mode, one of up to five

available User Displays will be shown. Pressing

NEXT

will

alternate between the following displays:

• Current time of day

• Treated water flow rate

• Service contact name and phone number (if entered)

• Remaining Capacity of treated water available

• Remaining days to regeneration (if Day Override is

programmed)

Pressing the

button while in the Capacity Remaining or

Days Remaining displays will decrease the capacity remaining

in ten gallon increments or the days remaining in one day

increments.

To clear the Service Call reminder

, press the

and

buttons simultaneously while the number and banner text

screen is displayed.

If the system has called for a regeneration that will occur at

the preset time of regeneration, the words REGEN TODAY will

alternate with the header on the display.

Utilizing the control valve’s built-in water meter, a water drop

flashes on the display when water is being treated (i.e. water is

flowing through the system).

Drop will flash while water

is being treated.

NEXT

NEXT

NEXT

Contact Screen

NEXT

Note: As an energy saving feature, the control will automatically turn off all SOLID BLUE or SOLID GREEN display

illumination and keypad illumination after about 5 minutes of the last keypad button push. Any further keypad touch will

cause the re-illumination of the display and keypad, and re-activate keypad control.