102

WARNING

If electric breakaway brakes do not operate

when trailer is uncoupled from the tow

vehicle, death or serious injury can occur.

Check emergency breakaway brake system

BEFORE each tow.

Tow Vehicle Operated Electric Brakes

The electric brakes that operate in conjunction with

the tow vehicle brakes must be “synchronized” so

that braking is properly distributed to the tow vehicle

brakes and the trailer brakes. For proper operation

and synchronization, read and follow the axle/brake

and the brake controller manufacturers’ instructions.

Magnets for all Electric Brakes

To make certain an electrically-operated braking sys-

tem will function properly; you must have your dealer

inspect the magnets at least once a year, or each

12,000 miles. See the brake manual for wear and cur-

rent inspection instructions.

Trailer Connection to Tow Vehicle

Coupler and Ball

The coupler on the trailer connects to the ball at-

tached to the hitch on the tow vehicle. The coupler,

ball and hitch transfer the towing forces between the

tow vehicle and the trailer. Before each tow, coat the

ball with a thin layer of automotive bearing grease to

reduce wear and ensure proper operation; and check

the locking device that secures the coupler to the ball

for proper operation.

If you see or feel evidence of wear, such as flat spots,

deformations, pitting or corrosion, on the ball or

coupler, immediately have your dealer inspect them

to determine the proper action to prevent possible

failure of the ball and coupler system. All bent or

broken coupler parts must be replaced before towing

the trailer.

The coupler handle lever must be able to rotate freely

and automatically snap into the latched position. Oil

the pivot points, sliding surfaces, and spring ends

with SAE 30W motor oil. Keep the ball pocket and

latch mechanism clean. Dirt or contamination can

prevent proper operation of the latching mechanism.

When replacing a ball, the load rating must match or

exceed the GVWR of the trailer.

Fifth Wheel Kingpin

Before each tow, inspect the fifth wheel and kingpin

for wear, and coat the contact surface of the fifth

wheel plate with water-resistant Lithium-base grease.

If you see evidence of wear on the fifth wheel or king-

pin, immediately have your dealer inspect them to

determine the proper action to prevent failure of the

fifth wheel and kingpin system.

Landing Leg or Jack

If a grease fitting is present, you must use a grease

gun to lubricate the jack mechanism.

Grease the gears in the top of hand-cranked jacks

once a year, by removing the top of the jack and

pumping or hand packing grease into the gears.

Lights and Signals

Before each tow, check the trailer taillights, stoplights,

turn signals and any clearance lights for proper opera-

tion. This also includes your tow vehicle’s lighting. A

burned out bulb can create an unsafe condition by

reducing your ability to signal your intentions to other

drivers. When replacing exterior bulbs, take care that

the sealant around the light fixture is not disturbed.

This can cause a potential water leak. Refer to the bulb

replacement chart for the proper replacement bulbs.

WARNING

To avoid collisions, taillights, stoplights and

turn signals must work.

Wiring

Make sure the connector-plug prongs and recep-

tacles are clean. Lightly coat all electrical terminal

connections with non-conducting (dielectric), light

waterproof grease. Clean the prongs with very fine

sandpaper, being careful not to damage the contact

area.

Battery

Your trailer may be outfitted with a battery that oper-

ates lighting, electric landing gear, slide-outs or

other accessories. The battery may be kept charged

either by the tow vehicle or by the generator or shore

power.

A disconnect switch may be provided to disconnect

the battery when you do not plan to be using the

trailer for an extended period, such as seasonal stor-

age. If there is no disconnect switch, then remove the

cables from the battery terminals.

The battery must be kept in a charged condition

during storage. The battery could freeze and break if

it becomes discharged.

Summary of Contents for 1130

Page 6: ...6 This page intentionally left blank ...

Page 8: ...8 This page intentionally left blank ...

Page 10: ...10 This page intentionally left blank ...

Page 12: ...12 This page intentionally left blank ...

Page 22: ...22 This page intentionally left blank ...

Page 28: ...28 This page intentionally left blank ...

Page 34: ...34 This page intentionally left blank ...

Page 48: ...48 This page intentionally left blank ...

Page 54: ...54 This page intentionally left blank ...

Page 60: ...60 This page intentionally left blank ...

Page 68: ...68 This page intentionally left blank ...

Page 76: ...76 This page intentionally left blank ...

Page 86: ...86 This page intentionally left blank ...

Page 89: ......

Page 94: ...94 This page intentionally left blank ...

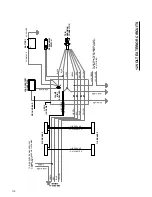

Page 113: ...113 SCHEMATICS ...

Page 120: ...120 ...

Page 121: ...121 ...

Page 123: ...123 ...

Page 131: ...131 ...

Page 132: ...132 ...