7

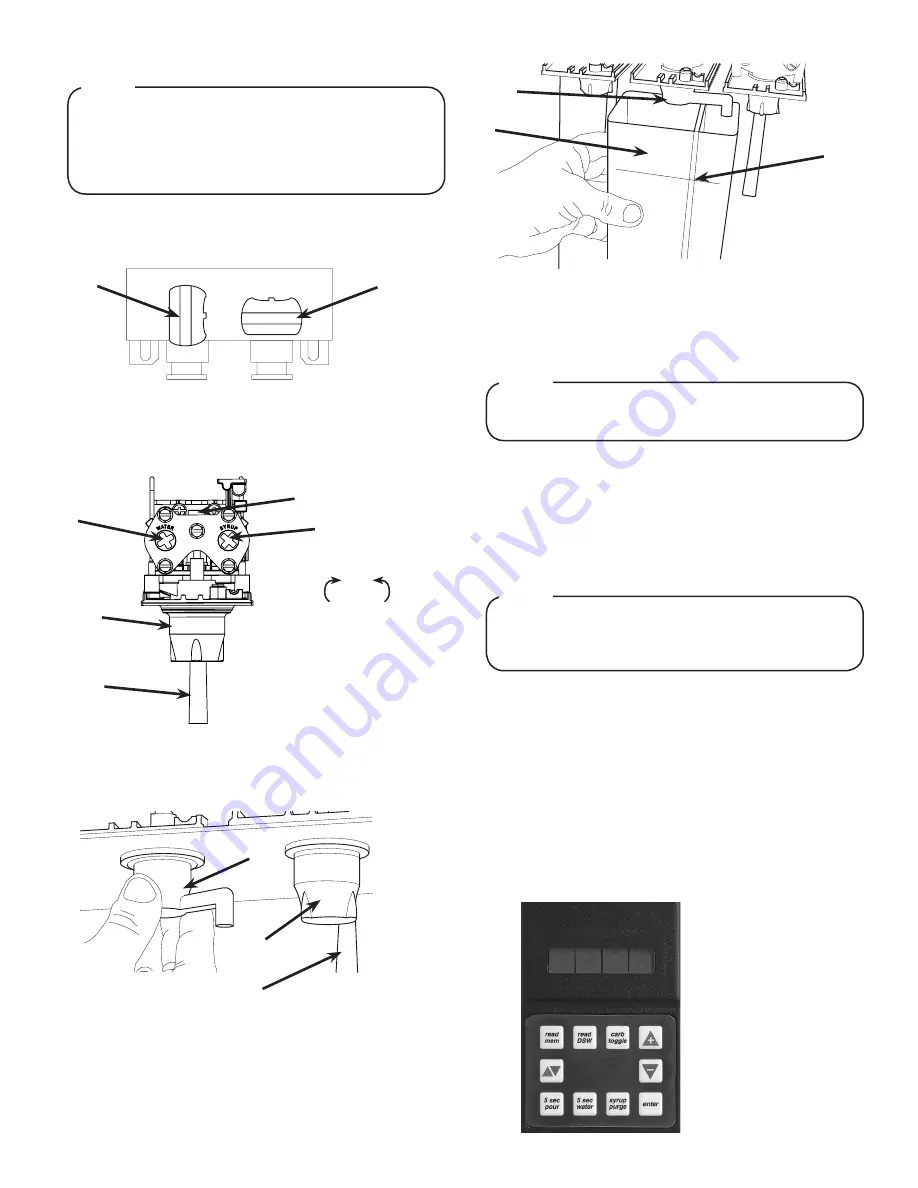

Adjust Water Flow Rate & Syrup/Water Ratio

The refridgeration unit should have been running for at

least one (1) hour before attempting to set flow rates

on valves. The drink temperature should be no higher

than 40°F (4.4°C) when flow rates are set. This is best

done after the unit has already made an ice bank.

NOTE

1. Set the three (3) way back block to dispense plain water or

carbonated water, depending on the type of syrup installed

on the previous page, for each valve.

2. Close syrup shut-off at mounting block for first valve.

3. Using a Lancer brix cup verify water flow rate (5 oz. in 4

sec.). Use a screwdriver to adjust if needed.

4. Remove nozzle by twisting counter clockwise and pulling

down, then remove diffuser by pulling down.

5. Install Lancer (yellow) syrup separator

(PN 54-0031)

in place

of nozzle.

A

B

Increase

Decrease

C

E

A. Flow Control, Water

B. Flow Control, Syrup

C. Nozzle (Diffuser inside)

D. Mounting Block (not shown)

E. Soda Lever

D

A

B

C

A. Syrup Separator

B. Nozzle

C. Soda Lever

6. Re-open syrup shut-off at mounting block.

7. Activate valve to purge syrup until steady flow is achieved.

8. Using a Lancer brix cup, activte the valve and capture a

sample. Verify that the syrup level is even with the water

level. Use a screwdriver to adjust if needed.

A

B

A. Plain Water ON

B. Syrup Closed

9. Repeat process for each valve.

10. Re-install the merchandiser, splash plate, cup rest, and drip

tray then reattach bonnet using the top bonnet screw.

A

B

C

A. Syrup Separator

B. Brix Cup

C. Verify Soda/

Water Level

Volumetric Valve Adjustment

The Volumetric Valve is an optional valve for the

CED-06 dispenser

NOTE

1. Remove the ID panel from the front of the first valve.

2. Insert the programmer’s 10-pin connector into the ID panel

plug located on the front of the circuit board.

3. When properly connected, the programmer will run a self

diagnostic test. The display will show all “8’s” with the

decimal points lighted. After about three (3) seconds, the

display indicates the setting of the dip switches.

If the programmer does not run its diagnostic test

properly, disconnect it and try plugging it in again. If

the programmer still fails, replace the programmer

NOTE

4. After the programmer is connected, Press the “Read Mem”

button.

5. Press the “Ratio +” or the “Ratio -” key until the desired ratio

is displayed.

6. Verify the drink type by pressing “Carb Toggle” to select “C”

for carbonated or “n” for non-carbonated.

7. Press the “Enter” button to program the valve with the setting

on the display.

8. Verify Ratio by pressing “Read Mem”.

9. Disconnect the programmer and repeat steps 4-9 for each

valve.

- Handheld Programmer

Volumetric Valve