9

A

B

C

A. Agitator Clip/Pin

B. Hub

C. Agitator Bar

17. Remove the Agitator bar and Hub from the Ice Bin.

18. Remove the plastic Ice Shroud from Ice Bin and set aside.

19. Using the Cleaning Solution (page 7) and a clean cloth or

soft brush, clean the Ice Chute Assembly, Ice Shroud, Auger,

all sides of the Ice Bin, and surface of the aluminum casting.

20. Using the Cleaning Solution and the sponge brush provided,

clean all interior surfaces of the ice chute and the ice chute

feed through.

21. Repeat Step 20 for all exterior surfaces of the dispenser.

22. Using hot water, thoroughly rinse away the cleaning solution.

23. Wearing sanitary gloves, use a clean cloth or towel and the

Sanitizing Solution (page 12) to wash all surfaces of remov

-

able parts, sides of the Ice Bin, and surface of the aluminum

casting.

24. Using the Sanitizing Solution and the sponge brush

provided, clean all interior surfaces of the ice chute and the

ice chute feed through.

14. Remove the Ice Chute Assembly by removing four (4)

screws that secure to unit and set aside.

15. Remove Auger by pulling straight out from unit and set aside.

16. Remove Agitator Clip and Pin from Agitator bar in Ice Bin.

Cleaning and Sanitizing Syrup Lines - Bag in Box

1. Disconnect syrup lines from BIB’s

2. Place syrup lines, with BIB connectors, in a bucket of warm

water.

3.

Activate each valve to fill the lines with warm water and flush

out syrup remaining in the lines.

4. Prepare Cleaning Solution described on previous page.

5. Place syrup lines, with BIB connectors, into cleaning

solution.

6.

Activate each valve until lines are filled with cleaning

solution then let stand for ten (10) minutes.

7. Flush out cleaning solution from the syrup lines using clean,

warm water.

8. Prepare Sanitizing Solution described on previous page.

9. Place syrup lines into sanitizing solution and activate each

valve to fill with sanitizer. Let sit for ten (10) minutes.

10.

Reconnect syrup lines to BIB’s and draw drinks to flush

solution from the dispenser.

11.

Taste the drink to verify that there is no off-taste. If off-taste

is found, flush syrup system again.

Following sanitization, rinse with end-use product

until there is no aftertaste. Do not use a fresh water

rinse. This is a NSF requirement. Residual sanitizing

solution left in the system creates a health hazard.

!

CAUTION

25. Repeat Step 24 for all exterior surfaces of the dispenser.

26. Wearing sanitary gloves, reassemble all removable parts.

Ensure agitator clip is locked.

27. Fill unit with ice and replace Top Cover.

28. Reconnect Dispenser to power source.

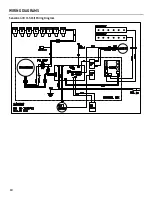

PLUMBING DIAGRAM