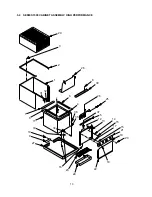

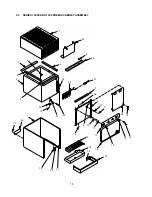

ITEM PART NO. DESCRIPTION

1

30-5107

Shroud, Fan, Bottom

2

30-5106

Shroud, Fan, Top

3

04-0504

Screw, 8 - 18 x 0.375

4

23-0985

Condenser

5

47-0344

Tube, Process

6

23-0982

Dryer Cap Assy

7

25-0048

Transformer, 220V/50-60Hz

-

25-0047

Transformer, 115V/50-60Hz

8

02-0041

Seal

9

02-0040

Seal, Extrusion

10

11-0118

Connector, Ground

11

47-1269/01 Tube, Suction

12

50-0041

Insulation, 31.385

13

04-0537

Washer, 0.467 ID x 0.923 OD x 0.060,

THK

14

03-0150

Retainer, Clip

15

07-0268

Handle

16

50-0029

Insulation, 2.500

17

50-0026

Insulation, 8.125

18

51-0061

Accumulator

19

50-0028

Boot

20

02-0114

Grommet

21

03-0049

Clip, Cord

22

06-0666

Label, 240V/60Hz

-

06-0460

Label, 230V/50Hz

-

06-0430

Label, 115V/60Hz

23

04-0032

Nut, 1/4 - 20, ST, NYLOCK

24

04-0063

Washer, Flat, 0.260 ID x 0.687 OD,

SS

25

04-0518

Rivet, 0.125 DIA x 0.328, LG

26

47-1337

Tube, Outlet

27

06-1532

Label, Wiring Diagram, EIBC

28

52-1369

Fan Motor Assy, 115V/60Hz

-

52-1378

Fan Motor Assy, 220-240V/50-60Hz

28A 04-0060

Nut, Fan Blade

28B 02-0413

Silencer, Fan Blade

28C 91-0009

Motor, Fan, 220V/50-60Hz

-

91-0007

Motor, Fan, 115V/60Hz

28D 30-5845

Bracket, Fan Motor

28E 07-0354

Fan Blade

28F 06-0670

Label, 230V/50-60Hz

-

06-0433/01 Label, 115V/60Hz

28G 04-0059

Screw, 8 - 36 x 0.375

29

52-1259

Agitator Motor Assy, 115V/60Hz

-

52-1379

Agitator Motor Assy,

220-240V/50-60Hz

29A 91-0086

Motor, Agitator, 220V/50-60Hz

-

91-0084

Motor, Agitator, 115V/60Hz

29B 02-0032

Washer, Rubber, 1.0 Inch OD

29C 06-0634

Label, 230V/50Hz

-

06-0633

Label, 115V/60Hz

29D 05-0502

Propeller, 2.250 DIA

29E 30-5113/01 Bracket, Agitator Motor

29F 05-0424/01 Propeller, 2.625 DIA

29G 04-0059

Screw, 8 - 36 x 0.375

30

06-0856/01 Label, Fill Hole

31

52-2014

Electronic Ice Bank Control (EIBC)

32

47-2025

Tube, High Side

33

04-0394

Screw, 6 - 32 x 0.500

34

52-2008

Harness Assy, Trans, Sec

35

52-2027

Harness Assy, Ground

36

52-1773

Probe Assy

37

30-7007

Retainer Strip

38

50-0302

Baffle, Rubber, Right

39

50-0303

Baffle, Rubber, Left

40

83-0038

Compressor, 240V/60Hz

40A 12-0028

Relay

40B 12-0253

Overload

40C 12-0260

Start Capacitor

-

- - - - - - -

Refrigerant, R-134A Only, 6.5 Ounces

-

83-0034

Compressor, 230V/50Hz

A

12-0031

Relay

B

12-0032

Overload

-

- - - - - - -

Refrigerant, R-134A Only, 6.5 Ounces

-

83-0033

Compressor, 115V/60Hz

A

12-0005

Relay

B

12-0223

Overload

-

- - - - - - -

Refrigerant, R-134A Only, 6.5 Ounces

41

04-0538

Cap Plug

42

23-1203/01 Evaporator

43

23-0993/02 Deck Assy

44

04-0260

Screw, 10 - 16 x 0.625

5.3

SERIES 1500 REFRIGERATION DECK ASSEMBLY, R-134A, WITH LANCER ELECTRONIC ICE

BANK CONTROL (EIBC); PN 82-2050E, 115V/60HZ; PN 82-2099E, 230V/50HZ; PN 82-2048E,

240V/60HZ; EXPORT ONLY (CONTINUED)

12

ITEM PART NO. DESCRIPTION