17

Section 1: Assembly and Set-Up

8/15/12

RCR3596, RCRM3596, RCR3510 & RCRM3510 Rotary Cutters 312-517M

Table of Contents

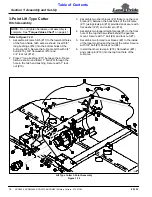

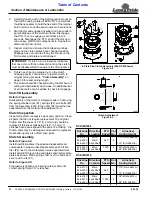

3-Point Hook-Up

Refer to Figure 1-9 on page 15:

!

DANGER

A Crushing Hazard exists when hooking-up equipment to a

tractor. Do not allow anyone to stand between tractor and

implement while backing-up to implement. Do not operate

hydraulic 3-Point lift controls while someone is directly

behind tractor or near implement.

!

WARNING

Always disengage PTO, engage parking brake, shut off

tractor, remove ignition key, and wait for all moving parts to

come to a complete stop before dismounting from tractor.

1.

Locate the cutter on a flat level surface.

2.

Determine the hitch category of the tractor that will

be used:

a. Category I tractors will have a lower hitch link

hole diameter of 7/8". The top link hole diameter

(cutter end) will be 3/4".

b. Category II tractors will have a lower hitch link

hole diameter of 1 1/8". The top link hole diameter

(cutter end) will be 1".

c. Category III tractors will have a lower hitch link

hole diameter of 1 7/16". The top link hole

diameter (cutter end) will be 1 5/16".

Refer to Figure 1-9 on page 15:

3.

Remove lower linch pins (#3) and hitch pins (#1) from

the deck. Remove upper cotter pin, flat washer and

hitch pin (#5) from the deck.

4.

Slowly back tractor up to the cutter while using the

tractor’s 3-point hydraulic control to adjust the lower

link arms up or down to match the tractor’s lower arm

pin holes to the cutter hitch pin holes. The lower lift

arms of a Category 2 tractor will be positioned to the

outside of the cutters lower hitch lugs on RCR35596

& RCRM35596 cutters.

5.

Insert hitch pins (#1) and secure with linch pins (#3).

6.

Connect the top link (#4) to the upper pivot hitch

using 1" clevis pin (#5), washer and cotter pin

supplied. Bend cotter pin after inserting to prevent it

from falling out.

7.

The lift link rods on your tractor’s 3- point hitch should

be adjusted to allow for lateral float. Please consult

you tractor’s manual for adjusting instructions.

Driveline Installation

!

DANGER

Do not engage tractor PTO while hooking-up and unhooking

driveline or while someone is standing near the driveline. A

person’s body and/or clothing can become entangled in the

driveline resulting in serious injury or death.

!

DANGER

All guards and shields must be installed and in good working

condition at all times during cutter operation.

!

WARNING

Always disengage PTO, engage parking brake, shut tractor

engine off, remove switch key, and wait for blades to come to

a complete stop before dismounting tractor.

!

WARNING

Do not over-speed PTO or machine breakage may result.

Some tractors are equipped with multispeed PTO ranges. Be

certain your tractor’s PTO is set for the cutter’s rated PTO

speed. See Specifications & Capacities for rated PTO speed.

!

WARNING

Do not use a PTO adaptor with a quick hitch. A PTO adapter

will increase strain on the tractor’s PTO shaft resulting in

possible damage to shaft and driveline.

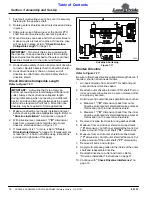

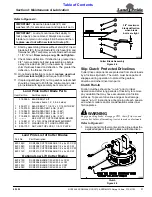

1.

Park tractor on a level surface. Slowly engage tractor

3-point lift lever to raise cutter until gearbox shaft is in

line (level) with tractor PTO shaft.

2.

Support cutter deck at this height with support jacks

or blocks to keep cutter from drifting down.

3.

Place gear selector in park, set park brake, shut

tractor off and remove switch key.

4.

Remove rubber protective sleeve from gearbox input

shaft and discard.

5.

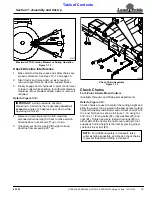

Unsnap one end of gearbox shield access doors and

rotate doors open.

6.

Attach slip-clutch end of driveline (#16) to gearbox

input shaft. Make certain that the slip-clutch is fully

onto the shaft splines. Tighten conical dog pin on

back side of slip-clutch to 45-50 ft-lb torque.

IMPORTANT: An additional driveline may be

required if cutter is to be used on more than one

tractor, especially if a Quick Hitch is used.

The driveline must be lubricated before putting it into

service. Refer to “Lubrication” on page 35.

The tractor’s PTO shaft and cutter gearbox shaft

must be aligned and level with each other during

installation of driveline.