38

Section 4: Grass Seed Rate Adjustment

MPS2607, MPS2609, & MPS2611 Multi-Purpose Seeder 329-301M

Table of Contents

8/8/23

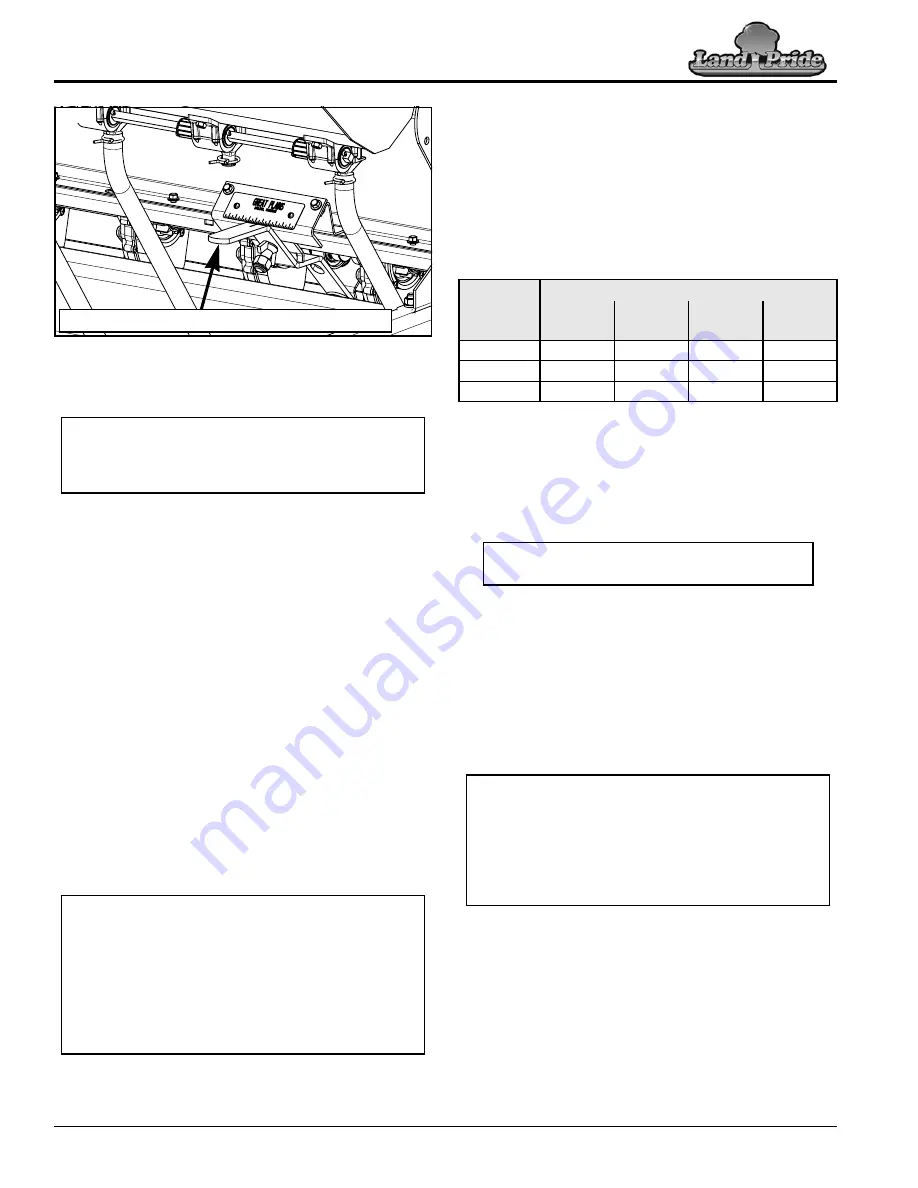

Grass Seed Rate Adjustment Lever

Figure 4-2

Grass Seed Rate Adjustments

1.

Use English seed charts on pages 40-42 and Metric

seed charts on pages 43-45 to help determine

seeding rate.

a. Decide which drive range is required (low or high

range). If necessary, change the grass seeds

transmission speed to accommodate correct

speed range. See

“Grass Seeds Transmission”

on page 32.

b.

Refer to

Figure 4-2:

Move seed rate adjustment

lever to cup setting number obtained from the

seed rate charts. For best results, first move

adjustment lever all the way to the left and then to

the desired setting. Increase setting if seed is

lighter than average. Decrease setting if seed is

heavier than average.

2.

Refer to

Figure 2-13 on page 33:

Disengage small

seeds with lock in/out pin (#5) and native seeds with

lock in/out pin (#3).

3.

Continue with

“Calibrate Grass Seed Dispersal”

below.

Calibrate Grass Seed Dispersal

1.

Attach seed rate crank to the all seeds drive sprocket.

Refer to

“Seed Rate Crank Instructions”

on

page 39.

Grass Seed Rate Adjustment Lever (Cup Setting)

73481

NOTE:

To determine seed rates for seeds not listed

in the charts, compare weight and size to those

listed and use a similar setting. Follow steps 1 to 11

to calibrate seed rate.

IMPORTANT:

Seed rates provided in the charts may

be inconsistent with actual seeding rates due to

seed size, weight, treatment, moisture content, ratio

of inert material to seed, different seed mixtures,

humidity, and ground preparation. Minor

adjustments to the cup setting may be needed to

compensate. We recommend that you test and adjust

your seeder using the calibration procedures listed

below to help ensure an accurate seeding rate.

2.

Partition off three of the seed discharge openings

located inside the grass seeds seedbox.

3.

Pour seed over the three discharge openings.

Do not

allow any seed to reach any of the other openings.

4.

Crank rear roller clockwise to make sure the drive

system is working properly and the seed cups are

free from foreign matter.

5.

Place a drop cloth under the seeder to collect all of

the seeds that are metered out.

6.

Crank rear roller clockwise the number of rotations

noted in the table above. Be sure to check the three

feed cups to make sure each cup has plenty of seed

coming into it.

7.

Weigh the seed which has been metered out and

divide that weight by three to get the number of

pounds or kilograms per seed cup.

8.

Next, multiply number of pounds or kilograms per

seed cup by the number of seed cups on the grass

seeds seedbox to arrive at weight “A”.

9.

If Weight “A” is calculated based on:

1/10 acre, then “A” x 10 = lbs/acre

1000 sq ft, then “A” x 43.56 = lbs/acre

1000 sq ft, then “A” x 1 = lbs/1000 sq ft

1/20 hectare, then “A” x 20 = kgs/hectare

100 sq meters, then “A” x 100 = kgs/hectare

100 sq meters, then “A” x 10 = kgs/1000 sq m

10. If calculated grass seed rate is different than the

suggested settings in the charts, then increase or

decrease the seed cup adjustment lever shown in

Figure 4-2.

11. Repeat calibration procedure if seed cup adjustment

lever position was moved in the step above.

12. Remove and store seed rate crank. For detailed

instructions, refer to

“Store Seed Rate Crank”

on

page 39.

Model

No

No. of Rear Roller Rotations to Cover

1/10

Acre

1000 Sq.

Ft.

1/20

Hectare

100

Sq. M

MPS2607

266

61

329

66

MPS2609

207

48

256

52

MPS2611

169

39

209

42

NOTE:

If total weight for 3 seed cups is in

ounces, divide that weight by 48 instead of 3.

NOTE:

Field conditions will affect seeding rates.

Check amount of seed being used by noting size of

area being seeded, amount of seed added to the

seeder, and level of seed in the seedbox.

Minor adjustments to the seed rate adjustment lever

may be necessary if the seeder is seeding more or

less seed than desired.