Section 1: Assembly & Set-Up

10/26/17

10

Section 1:

Assembly & Set-Up

Tractor Requirements

Tractor horsepower rating should be between 15 & 30

PTO horsepower. Tractors outside this horsepower range

must not be used.

The rear power take-off (PTO) speed must be capable

540 RPM and have a 1 3/ 8"-6 spline.

A 3-Point Category I hitch is required. The lower 3-Point

arms must be stabilized to prevent side-to-side

movement. Most tractors have sway blocks or adjustable

chains for this purpose.

The tractor

MUST

be equipped with protective equipment

designed to shield the operator from thrown objects and

from tractor roll over. An enclosed tractor cab with a Roll

Over Protective Structure (ROPS) may qualify. See

tractor’s manual for type of protection your tractor has.

Torque Requirements

Refer to

“Torque Values Chart”

determine correct torque values for common bolts.

Dealer Preparations

This Grooming Mower has been partially assembled at

the factory. Some assembly and preparation are still

required before the mower is ready for operation and can

be attached to the customer tractor.

Make sure that the intended tractor conforms to the

Tractor Requirements stated above. Also, read and

understand the Operator’s Manual for the Grooming

Mower. An understanding of how it works will aid in its’

assembly and setup.

Go through the

Pre-Assembly Checklist

before

assembling the mower. To speed up your assembly task

and make the job safer, have all needed parts and

equipment readily at hand.

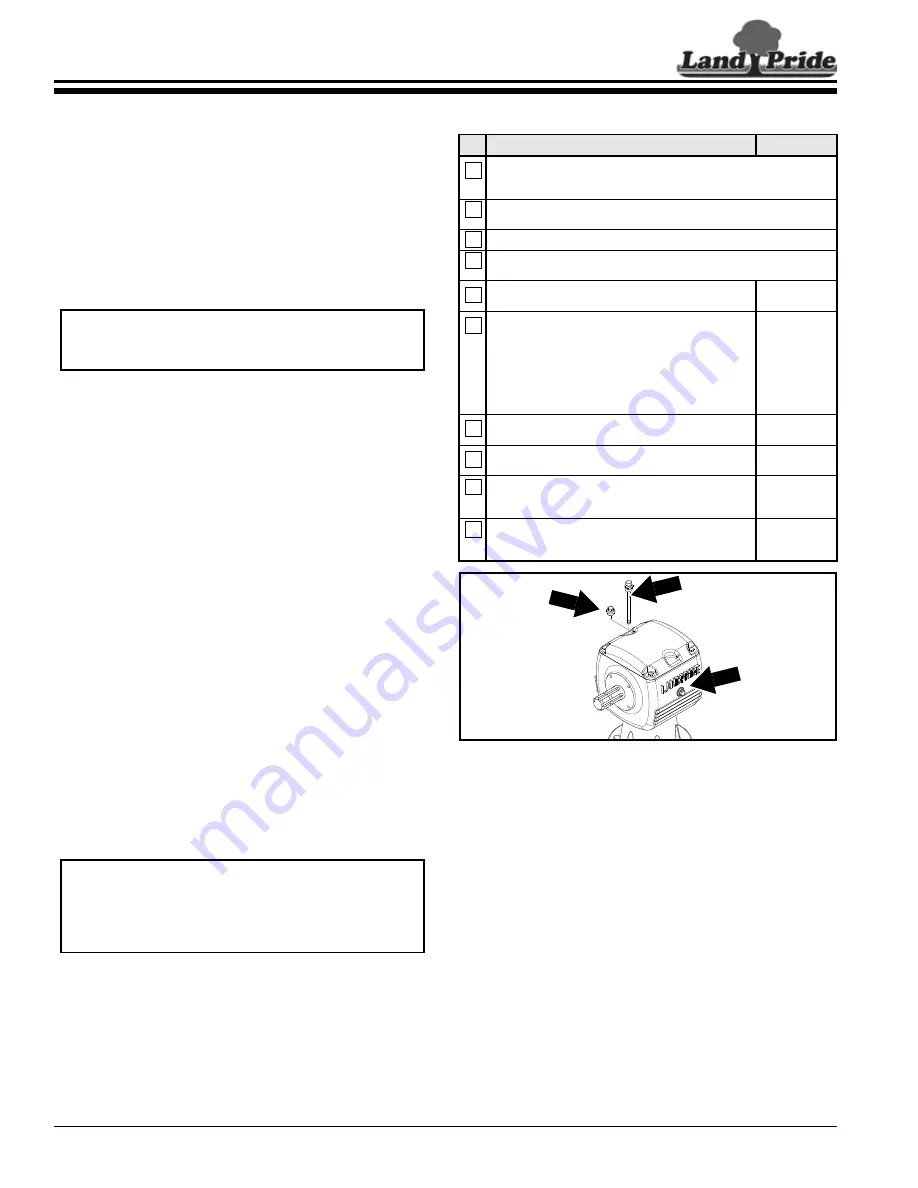

Vented Dipstick Installation

Refer to Figure 1-1:

A vented dipstick for the gearbox is included in a bag with

the manual. See your nearest Land Pride dealer if

dipstick is missing. Remove temporary red plug from top

of splitter gearbox and replace with supplied dipstick.

NOTE:

The tractor may need additional ballast to

maintain steering control. See tractor’s Operator’s

Manual to determine if additional ballast is required.

IMPORTANT:

Gearboxes are shipped with solid

Installation of Vented Dipstick

Figure 1-1

Upper 3-Point Hitch Assembly

Refer to Figure 1-2 on page 11:

1.

Remove angle shipping brackets (not shown) with

gauge wheel assemblies (#4) from mower frame.

2.

Remove rear hitch braces (#1), A-Frame hitch braces

(#2), and clevis hitches (#3) from shipping crate.

3.

Attach rear hitch braces (#1) to hole “A1” inside of

rear hitch mounting plates (#5) with 5/8" bolts and

flanged lock nuts (#6) provided in rear hitch plates.

Do not tighten nuts.

4.

Attach A-Frame hitch braces (#2) to holes “A2” inside

front hitch mounting plates (#7) with 5/8" bolts (#8)

and hex flanged lock nuts (#8) shipped holding rear

hitch braces (#1) together. Do not tighten nuts.

5.

Remove 5/8" x 5 1/2" lg. bolt, lock washer, and

nut (#11) from upper pivoting hitch (#9). Don’t let

spacer tube (#10) fall from upper pivoting hitch.

Pre-Assembly Checklist

Check

Reference

Make sure miscellaneous assembly tools are on hand: Hammer,

tape measure, hacksaw, assortment of wrenches & sockets,

3/8" drill, drill bits and spirit level.

Have a forklift or hoist with properly sized chains and safety

stands on hand capable of lifting 2500 lbs.

Have a minimum of two people available during assembly.

Check to see if auxiliary tractor weights are needed.

See Specifications on page 27 for mower weights.

Make sure all major components and loose parts

are shipped with the implement.

Operator’s

Manual

Double check to make sure all fasteners & pins are

installed in the correct location. Refer to the Parts

Manual if unsure.

NOTE:

All assembled hardware from the factory

has been installed in the correct location.

Remember location of a part or fastener if

removed. Keep parts separated.

Operator’s

Manual &

Parts Manual

Make sure working parts move freely, bolts are

tight & cotter pins are spread.

Operator’s

Manual

Make sure all grease fittings are in place and

lubricated.

Section 5

Page 25

Make sure all safety labels are correctly located

and legible. Replace if damaged.

Important

Safety

Information

Make sure all red reflectors are correctly located

and visible when implement is in transport

position.

30216

DO NOT

OVERFILL!

Oil Level

Plug

Solid

Plug

Vented Dipstick