Section 4: Options and Accessories

PD10, PD15, PD25 & PD35 Post Hole Diggers 317-048M

8/9/19

33

Alignment Handle, PD10

Part No. 317-162A

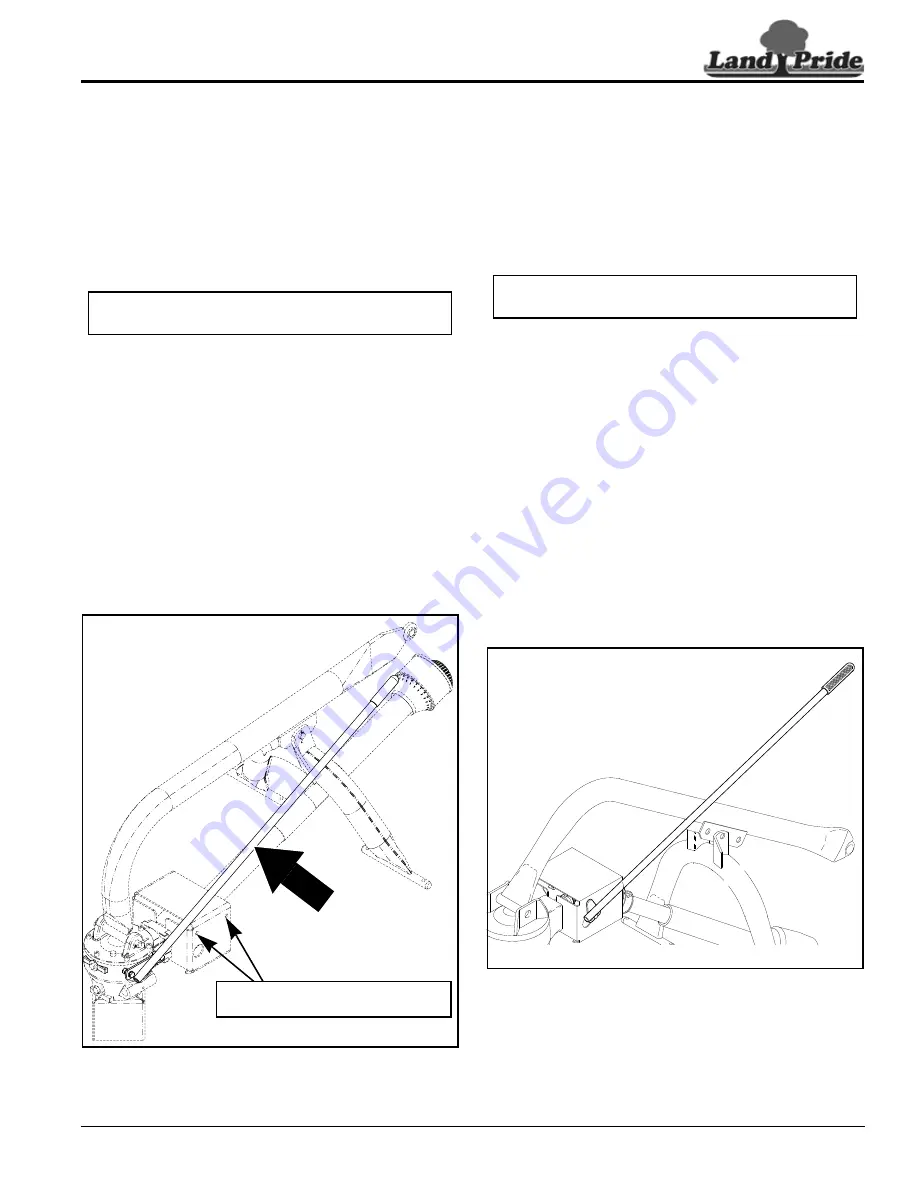

Refer to Figure 4-22:

The alignment handle, mounted to the gearbox or power

take-off shield, enables the operator to position the auger

tip on the ground from the tractor seat. Mount handle in

location suitable to the operator. Raise handle to move

auger tip toward the tractor or lowering handle to move

auger tip away from the tractor.

The alignment handle is bolted to the gearbox as shown

below with two hex head bolts and lock washers. Tighten

according to the

“Torque Values Chart for Common

Before using, check alignment handle for interferences

with the tractor and tractor operator. Its height, due to

various tractor sizes and configurations, may need to be

adjusted. If necessary, bend alignment handle arm up or

down to a height that will accommodate the tractor

operator.

Also, the arm may need to be cut-off at the grip end to

prevent it from interfering with the tractor operator and

tractor. First remove handle grip and then cut arm off to

an acceptable length. Remove all burs and replace grip.

PD10 Alignment Handle

Figure 4-22

NOTE:

Only the tractor operator should position the

auger tip.

20857

Alignment Handle

Alternate Mounting Location

Alignment Handle, PD15, 25, & 35

Part No. 317-042A

Refer to Figure 4-23:

The alignment handle, mounted to the driveline guard,

enables the operator to position the auger tip from the

tractor seat. Raise handle to move auger tip toward the

tractor or lowering handle to move auger tip away from

the tractor.

The alignment handle is bolted to the power take-off

guard as shown below with two hex head bolts and lock

washers. Tighten according to the

Before using, check alignment handle for interferences

with the tractor and tractor operator. Its height, due to

various tractor sizes and configurations, may need to be

adjusted. The adjustment, if necessary, is made by

removing the bottom fasteners and rotating the handle

either up or down to the desired position. Reinstall

fasteners and tighten according to the

Also, the arm may need to be cut-off at the grip end to

prevent it from interfering with both the tractor operator

and tractor. First remove handle grip and then cut arm off

to an acceptable length. Remove all burs and replace

grip.

PD15, 25, and 35 Alignment Handle

Figure 4-23

NOTE:

Only the tractor operator should position the

auger tip.

10436