Section 3: Operating Instructions

11/2/18

21

•

Operate only power machines equipped with a certified

Roll-Over Protective Structure (ROPS) and seat belt. Keep

folding ROPS in the “locked up” position when

appropriate. If ROPS is in the locked up position, fasten seat

belt snugly and securely to help protect against serious

injury or death from falling and machine overturn.

•

Do not operate a cutter with a hitch or hitch pin that is

excessively worn, bent, broken, or has structural cracks.

The hitch and/or hitch pin can break apart separating cutter

•

Perform scheduled maintenance. Check for loose

hardware, missing parts, broken parts, structural cracks,

and excessive wear. Make repairs before putting implement

back into service. Serious breakdowns can result in injury

•

Wait for blades to come to a complete stop before accessing

blade bolts through blade bolt access hole.

•

Do not use implement to tow other equipment unless it is

designed with a tow hitch. Doing so can result in loss of

control and damage the equipment.

•

Do not exceed rated cutting capacity of your cutter. See

specifications & capacities for specified cutting capacity.

Exceeding rated cutting capacity can damage drive

components, cutter blades, and deck components.

•

Buildup of debris around moving components and

gearboxes is a fire hazard. Keep rotating parts and

gearboxes free from debris to avoid serious injury and

•

Improper oil level can cause bearing failure and be a fire

hazard. Maintain proper gearbox oil level to avoid serious

•

Do not operate a broken or bent driveline. Such a driveline

will break apart while rotating at high speeds and can cause

serious injury or death. Always remove the implement from

use until the damaged driveline can be repaired or replaced.

•

The cutter must be operated with both wings attached.

Removing one wing will increase risk of rollover. Removing

one or both wings will expose blades. Blades rotating at

high speed will cut body extremities and throw objects.

CAUTION

!

To avoid minor or moderate injury:

Some tractors are equipped with two power take-off speeds.

Be certain your tractor’s power take-off is set at the

implement’s rated power take-off speed or equipment

breakage may result. RC models are rated for 540 rpm and

RCM models are rated for 1000 rpm.

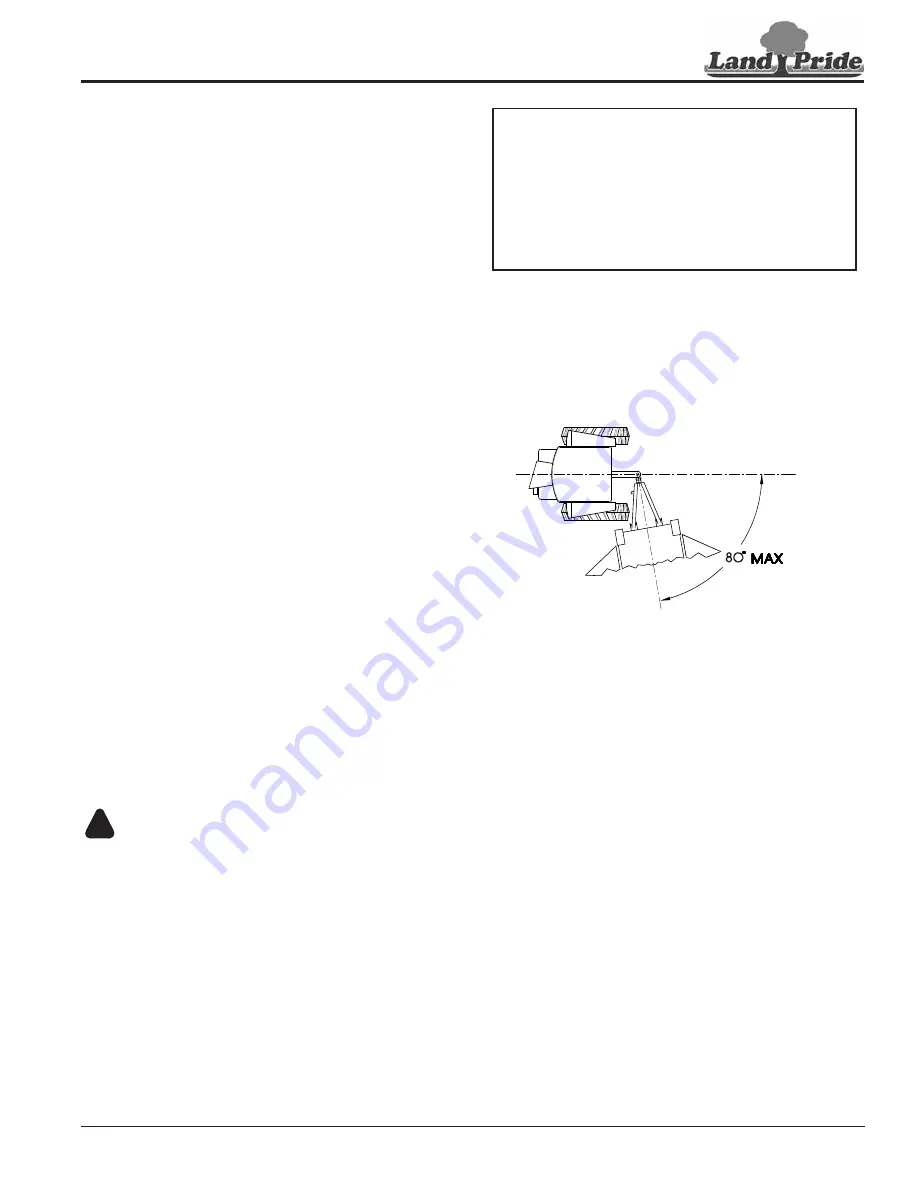

Tractor Turning Angle

Plan your field cutting to minimize number of turns,

especially extreme turning angles. Avoid tractor-to-cutter

turning angles that exceed 80

o

. If the turn cannot be

avoided, disengage power take-off and wait for the

driveline to stop rotating before making the turn.

Constant Velocity (CV) Driveline

Figure 3-3

IMPORTANT:

Maintain correct power take-off

IMPORTANT:

If wing driveline profile is bent or

20795