Section 1: Assembly & Set-up

7/13/20

RCD1884 Rotary Cutters 326-355M

11

Section 1:

Assembly & Set-up

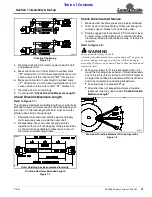

Vented Breather Plug Installation

Refer to Figure 1-1:

The right angle gearbox is shipped with vented breather

plug factory installed. The other gearbox is shipped with

vented breather plug packaged with the Operator’s

Manual in the manual tube. Remove temporary solid plug

from top of gearbox and replace with vented breather

plug. See your nearest Land Pride dealer if breather plug

is missing.

Vented Breather Plug Installation

Figure 1-1

IMPORTANT:

Gearboxes are shipped with solid

plugs in them to prevent oil loss during shipping and

handling. The solid plug on top of the gearbox must

be replaced with a vented dipstick before operating

33060

Remove

Solid Plug

Install Breather Plug During Assembly & Set-up

Factory Installed

Breather Plug

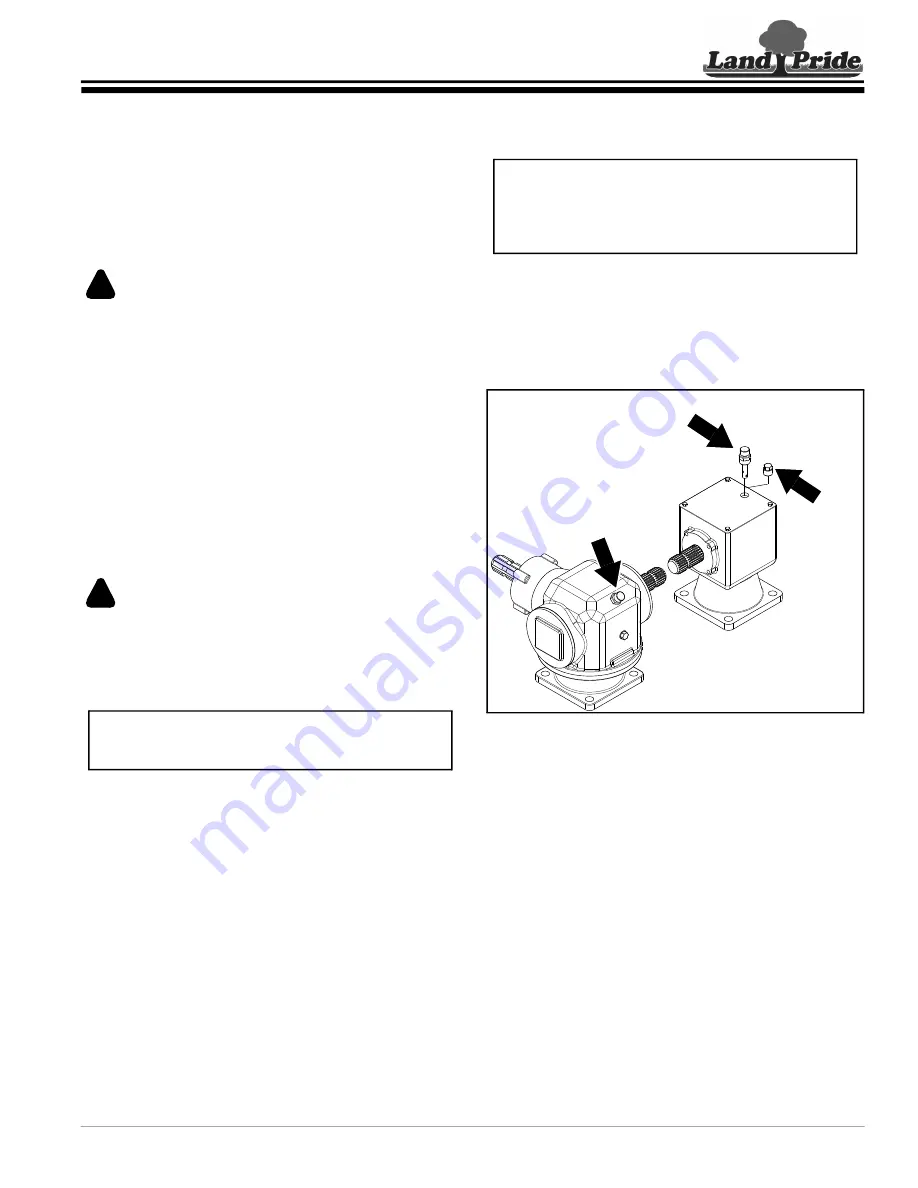

Tractor Requirements

Tractor horsepower and hitch category should be within

the range noted below. Tractors outside the horsepower

range must not be used.

Tractor Horsepower Rating. . . . . 35 to 60 horsepower

Hitch Category . . . . . . . . . . . . . . . . . . . . . . . . . Cat I

power take-off Speed . . . . . . . . . . . . . . . . . . .540 rpm

power take-off Shaft Type . . . . . . . . . .1 3/8"-6 Spline

WARNING

!

To avoid serious injury or death:

Lightweight tractors with rear attached implements may need

weights added to the front to maintain steering control.

Consult your tractor Operator’s Manual to determine proper

weight requirements and maximum weight limitations.

Torque Requirements

“Torque Values Chart for Common Bolt Sizes”

on page 37 to determine correct torque values when

bottom of chart for exceptions to common torque values.

Uncrating Instructions

WARNING

!

To avoid serious injury or death:

Always secure cutter with an overhead crane, fork lift, or

other suitable lifting device before removing hardware bags,

shipping components, bands, lag screws, or hitch pins. The

1. Secure cutter with a hoist or other lifting device

before removing shipping hardware.

2. Remove lag screws securing front face of cutter to

the crate.

3. Using lifting device, remove tension on hitch pins

securing clevis plates to shipping crate.

4. Remove hitch pins from clevis plates and lift cutter

from shipping crate. Gently lower unit onto the floor.

IMPORTANT:

Do not attach hoist to gauge wheel