Section 2: Optional Equipment

RCFM4014 Rotary Cutter 326-730M

12/11/18

21

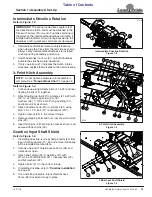

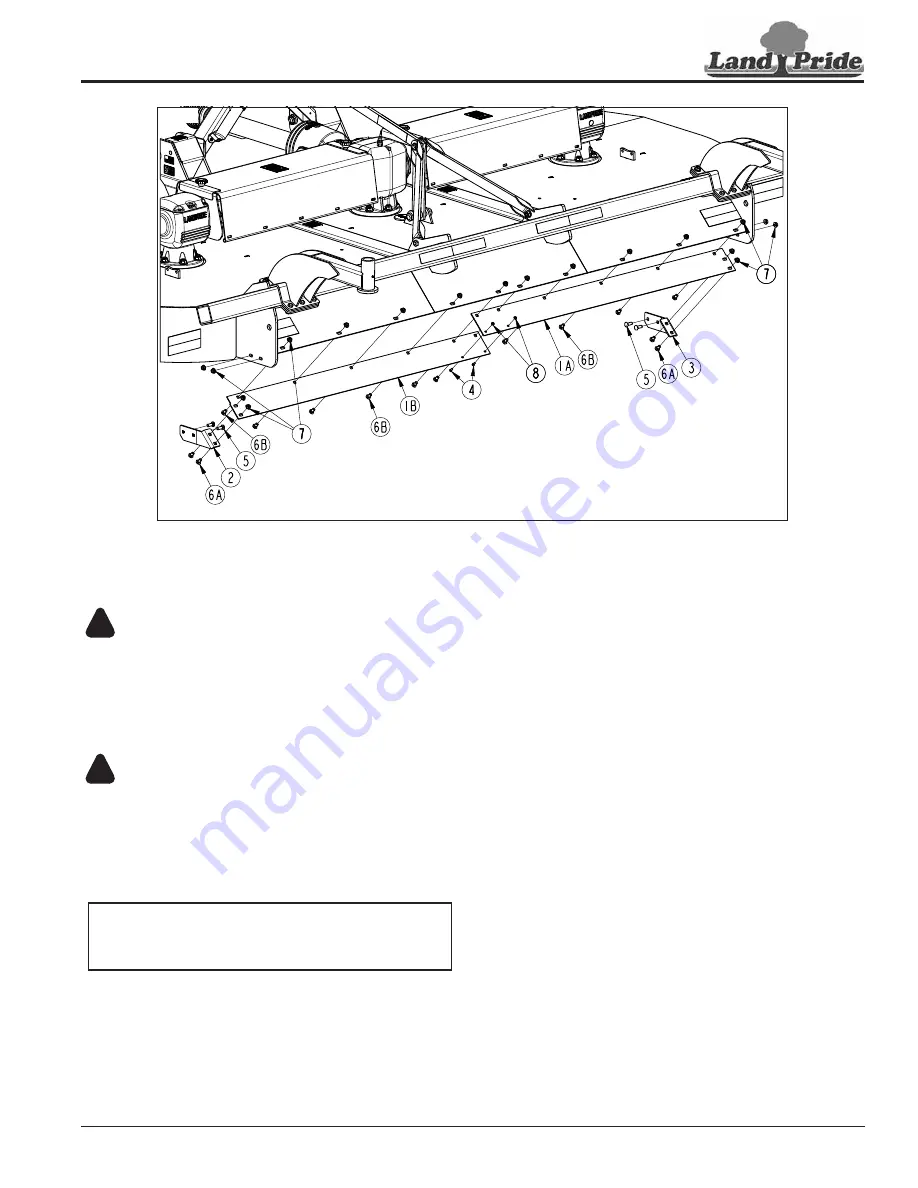

Rear Metal Guard

Figure 2-3

37162

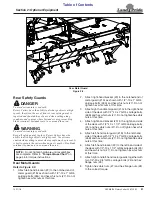

Rear Safety Guards

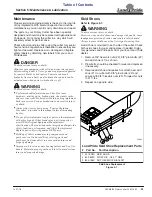

DANGER

!

To avoid serious injury or death:

Rotary Cutters have the ability to discharge objects at high

speeds; therefore, the use of front & rear safety guards is

required and should always be used when cutting along

roadways and in areas where bystanders are present. Stop

blade rotation if bystanders are in or around the area.

WARNING

!

To avoid serious injury or death:

Keep all safety guards in place. Rotary Cutters have the

ability to discharge objects at high speeds. Use extreme

caution when cutting in areas where people may be present. It

is best to operate the cutter when no one is nearby. Stop blade

rotation if someone is in or around the area.

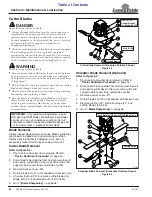

Rear Metal Guards

1.

Attach left-hand bracket (#2) to the notched end of

metal guard (#1B) as shown with 1/2"-13 x 1" GR5

carriage bolts (#6A) and hex whiz nuts (#7). Do not

tighten hex whiz nuts at this time.

NOTE:

Do not tighten hardware until assemblies

are complete. Refer to

“Torque Values Chart”

on

page 46 for torque instructions.

2. Attach right-hand bracket (#3) to the notched end of

metal guard (#1A) as shown with 1/2"-13 x 1" GR5

carriage bolts (#6A) and hex whiz nuts (#7). Do not

tighten hex whiz nuts at this time.

3. Attach right-hand metal guard (#1A) to the right-hand

side of the deck with 1/2"-13 x 1" GR5 carriage bolts

(#6B) and hex whiz nuts (#7). Do not tighten hex whiz

nuts at this time.

4. Attach right-hand bracket (#3) to the right-hand side

of the deck with 1/2"-13 x 1 1/2" GR5 carriage bolts

(#5) and hex whiz nuts (#7). Do not tighten hex whiz

nuts at this time.

5. Attach left-hand metal guard (#1B) to the left-hand

side of the deck with 1/2"-13 x 1" GR5 carriage bolts

(#6B) and hex whiz nuts (#7). Do not tighten hex whiz

nuts at this time.

6. Attach left-hand bracket (#2) to the left-hand side of

the deck with 1/2"-13 x 1 1/2" GR5 carriage bolts (#5)

and hex whiz nuts (#7). Do not tighten hex whiz nuts

at this time.

7.

Attach right and left-hand metal guards together with

two 1/4"-20 x 3/4" GR5 carriage bolts (#4) and hex

flange nuts (#8)

8. Tighten hex whiz nuts (#7) and hex flange nuts (#8)

to the correct torque.