Section 1: Assembly & Set-Up

RCFM4014 Rotary Cutter 326-730M

8/11/14

14

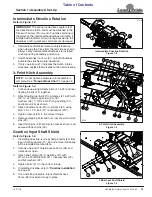

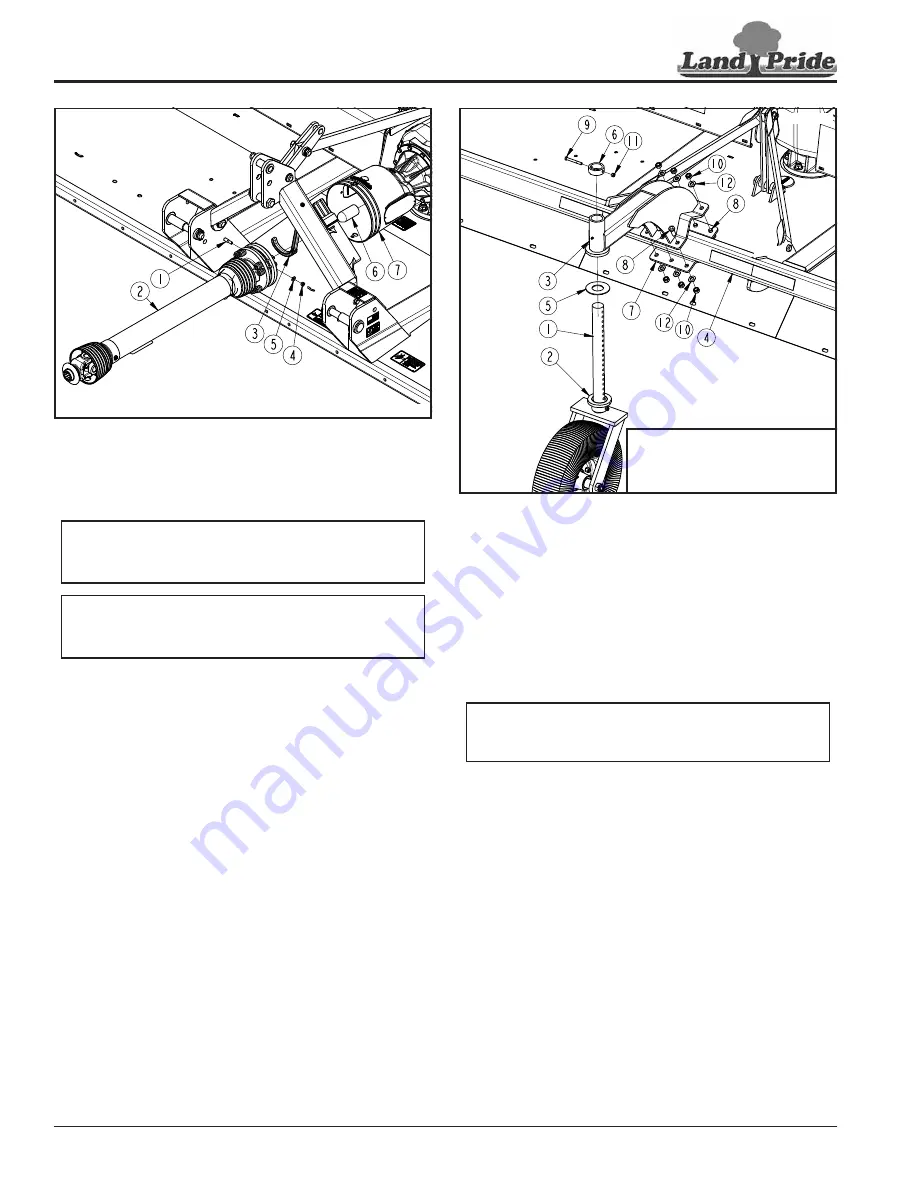

Installation of Center Tailwheel

Figure 1-7

Center Tailwheel Assembly

Depending on which option was purchased, the cutter

will be set-up with two or three tailwheels. If there are

three tailwheels, the third tailwheel is installed in the

middle of toolbar (#4). If only two tailwheels are provided,

skip to

“End Tailwheels for 38" & 40" Rows”

1.

Attach trailing arm (#3) to rear tool bar (#4) with

4" tube clamp (#7), 5/8"-11 x 2" GR5 bolts (#8), flat

washers (#12), and hex locknuts (#10). Make sure

trailing arm is centered on the rear tool bar and draw

all six nuts up snug. Do not tighten nuts until step #2.

2. Tighten the center two hex locknuts (#10) and then

the four corner locknuts (#10) in a crisscross pattern.

3. Repeat step 2 making sure all six nuts are tightened

to the correct torque.

4. Install large washer (#5) over tailwheel spindle (#1).

5. Insert tailwheel spindle (#1) into trailing arm (#3).

Push tailwheel up until adjusting collar (#2) is against

the trailing arm (#3).

6. Lower top collar (#6) over tailwheel spindle (#1) until

against trailing arm (#3).

7.

Secure top collar (#6) with 3/8"-16 x 3 1/4" GR8

bolt (#9) and nylock nut (#11). Tighten nylock nut to

the correct torque.

37160

IMPORTANT:

below must be followed when

tightening Lock nuts (#10).

IMPORTANT:

Discard hardware mounting tailwheel

to shipping crate. Use bolts, flat washers, and

locknuts in bolt bag to mount tailwheel to cutter axle.

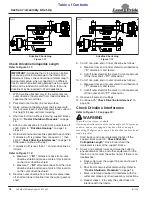

Driveline Installation

Figure 1-6

Driveline Installation

1.

If not already done, remove shaft protector (#6) from

gearbox input shaft and discard.

2. If not already done, unsnap one end of gearbox

shield access doors (#7) and rotate doors open.

3. Remove existing nut (#4), flat washer (#5), and

conical dog pin (#1) from slip-clutch end of

driveline (#2).

4. Slide u-joint on slip-clutch end of driveline (#2) onto

gearbox input shaft. Make certain the slip-clutch is

fully onto the shaft splines.

5. Attach slip-clutch end of driveline to gearbox input

shaft with removed conical dog pin (#1), flat

washer (#5), and nut (#4). Tighten conical dog

pin (#1) to 45-50 ft-lb torque.

6. Push/pull on driveline yoke to ensure it is securely

fastened to the gearbox shaft.

7.

Rotate driveline support (#3) down and place

driveline (#2) in driveline support (#3).

8. Rotate gearbox shield access doors (#7) closed and

snap in place.

37157

IMPORTANT:

The drivelines must be lubricated

before putting them into service. Refer to

NOTE:

If preferred, the front guards may be

assembled first. See