Section 5: Maintenance & Lubrication

RCFM4014 Rotary Cutter 326-730M

12/11/18

35

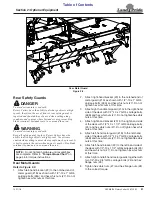

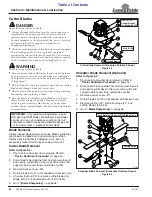

Fixed Blade Removal (Optional)

1.

Shut tractor and cutter down properly. Refer to

2. Disconnect main driveline from tractor power take-off

and secure cutter deck in the up position with solid

supports before servicing underside of cutter.

3. Remove hex whiz nut (#4) and bolt (#3).

4. Remove hex flange top locknut (#5), bolt (#2), and

fixed blade (#6).

5. Go to

Fixed Blade Components (Front Mount (#1) Shown)

Figure 5-4

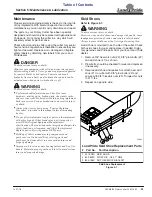

Blade Sharpening

Blades should be sharpened at the same angle as the

original cutting edge. Paired blades must be replaced or

re-ground at the same time to maintain proper balance.

Take the following precautions when sharpening blades:

1.

Do not remove more material than necessary.

2. Do not heat and/or pound out a cutting edge.

3. Do not grind blades to a razor edge. Leave a blunt

cutting edge approximately 1/16" thick.

4. Always grind cutting edge so end of blade remains

square to cutting edge and not rounded.

5. Do not sharpen back side of blade.

6. Both blades should weigh the same after sharpening

with not more than 1 1/2 oz. difference.

Blade Installation

WARNING

!

To avoid serious injury or death:

•

A locknut that has been removed can lose its thread locking

properties. Reusing a used locknut can result in a thrown

blade. Always use a new locknut when installing blades.

•

Cutter blades must be 90 deg. to each other to be in time or

blades will contact each other when hitting solid objects

such as tree stumps, rocks and earth.

37189

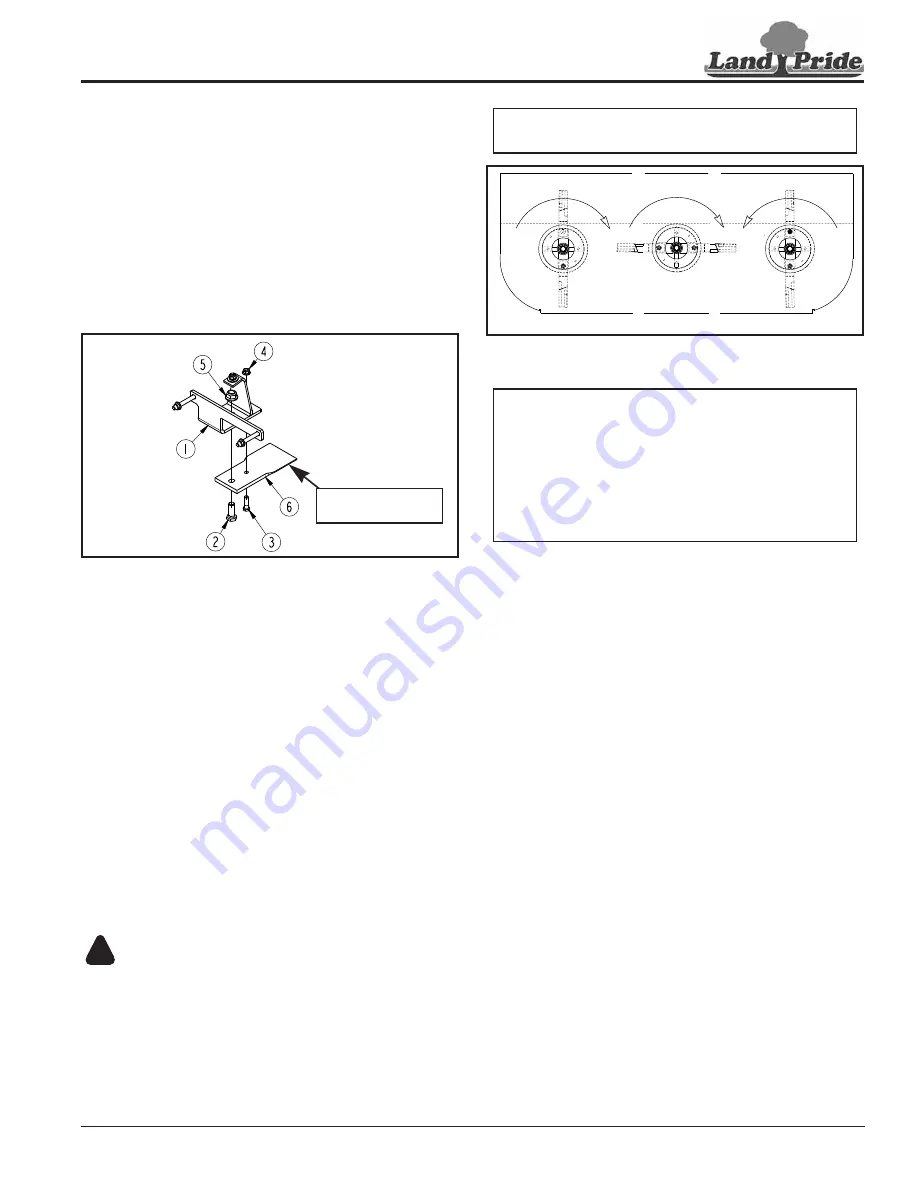

Face Beveled Edges

of Flat Blade Down

Blade Position and Direction of Rotation

Figure 5-5

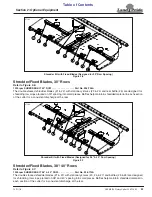

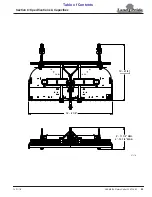

Cutter Blade & Dish Pan Installation

Refer to Figure 5-2 on page 35:

1.

Be sure to read Important Notes under

on this page before installing blades.

2. Insert blade bolt (#1) through blade (#6), dish

pan (#4), and flat washer (#2). Secure blade with a

new 1 1/8"-12 hex top locknut (#3)

. Torque hex top

locknut to 450 ft-lbs.

3. If replacing dishpan (#4), castle nut (#7) on gearbox

output shaft should be torqued to 550 ft-lbs minimum

and secured with cotter pin (#8) with both legs bent

opposite directions around the nut.

4. Replace access rubber plug (#5) and reconnect main

driveline to tractor power take-off shaft.

Shredder Blade & Blade Bar Installation

Refer to Figure 5-3 on page 35:

1.

Be sure to read instructions under

on this page before installing blades.

2. Insert bolt (#3) through blade bushing (#1), cutter

blade (#5), blade bar (#2), flat cutter blade (#6), and

blade bushing (#1). Secure blade with a

new 1"-8

hex top locknut (#4)

and torque to 450 ft-lbs.

3. If installing blade bar (#2), torque castle nut (#8) on

gearbox output shaft to 550 ft-lbs minimum and

secure by bending both legs of cotter pin (#9)

opposite directions around the castle nut.

IMPORTANT:

Examine blade bolts, washers, and

bushings for excessive wear and replace if worn.

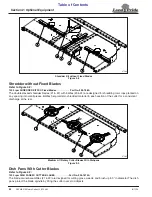

CW ROTATION

CCW ROTATION

CW ROTATION

REAR OF CUTTER VIEWED FROM THE TOP

37173

IMPORTANT:

Make certain when installing cutter

blades that they are rotated 90 degrees to the

adjacent blades as shown in Figure 5-5.

IMPORTANT:

To ensure correct blade placement,

carefully check cutting edges of blades in relation to

blade rotation shown in Figure 5-5. Cutting edge

must lead in rotation and airfoil (lift) must be oriented

towards the top of the deck.