Section 5: Maintenance & Lubrication

RCFM4014 Rotary Cutter 326-730M

12/11/18

37

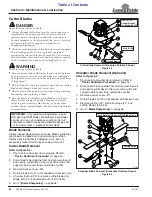

Clutch Disassembly, Inspection & Assembly

If clutch run-in procedure above indicated that one or more

friction disks did not slip, then the clutch must be

disassembled to separate the friction disks.

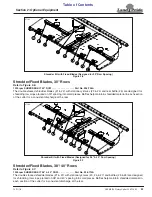

Disassembly

Disassembly of clutch is simply a matter of first removing

spring retainer nuts (#1), springs (#2), and bolts (#3) from

the assembly. Each friction disk (#4) must then be

separated from the metal surface adjacent to it.

Inspection

Inspect all parts for excessive wear and condition. Clean

all parts that do not require replacement.The original

friction disk thickness is 1/8" (3.2mm) and should be

replaced if thickness falls below 3/64" (1.1mm). If

clutches have been slipped to the point of “smoking”, the

friction disks may be damaged and should be replaced.

Heat build-up may also affect the yoke joints.

Assembly

Reassemble each friction disk (#4) next to the metal plate

it was separated from. Install bolts (#3) through the end

plates and intermediate plates as shown. Place springs

(#2) over the bolts and secure with nuts (#1).

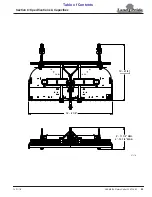

Refer to Figure 5-7 on page 37:

Progressively tighten each spring retainer bolt until

correct spring height “A” is reached.

Clutch Disassembly/Assembly

Figure 5-8

IMPORTANT:

Not all clutches are assembled the

23554

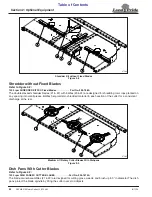

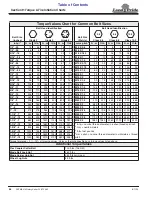

Intermediate Drivelines

Intermediate Driveline Maintenance

Figure 5-9

Intermediate Driveline Rotation Direction

Figure 5-10

Intermediate Driveline Rotations

Intermediate drivelines rotate counterclockwise when

viewing the T-box from the left side. Always verify

intermediate drivelines are installed correctly when

assembling them to the T-box.

IMPORTANT:

Shaft clamping cotter bolt (#1) must

be tightened after first 8 hours of use and thereafter

every 40 hours. Tighten nut to 100 ft-lbs or 136 Nm.

Driveline telescoping tubes must be greased every

40 hours through grease zerk (#2). Refer to

“Intermediate Driveline Profile”

detailed instructions. Excessive end thrust due to

lack of grease will shear clamping cotter bolt (#1).

37186

37214

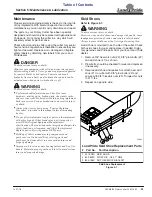

IMPORTANT:

The spring loaded flex couplers (#2)

are directional rotation and must be attached to the

T-box with arrows (#1) on end of clutches pointing in

the direction the intermediate drivelines will rotate. If

installed with indicator arrow rotating backwards, the

drivelines and/or gearboxes can become damaged.