Section 8: Troubleshooting

RCFM4014 Rotary Cutter 326-730M

12/11/18

45

Section 8:

Troubleshooting

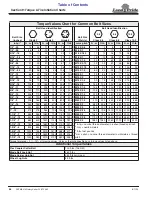

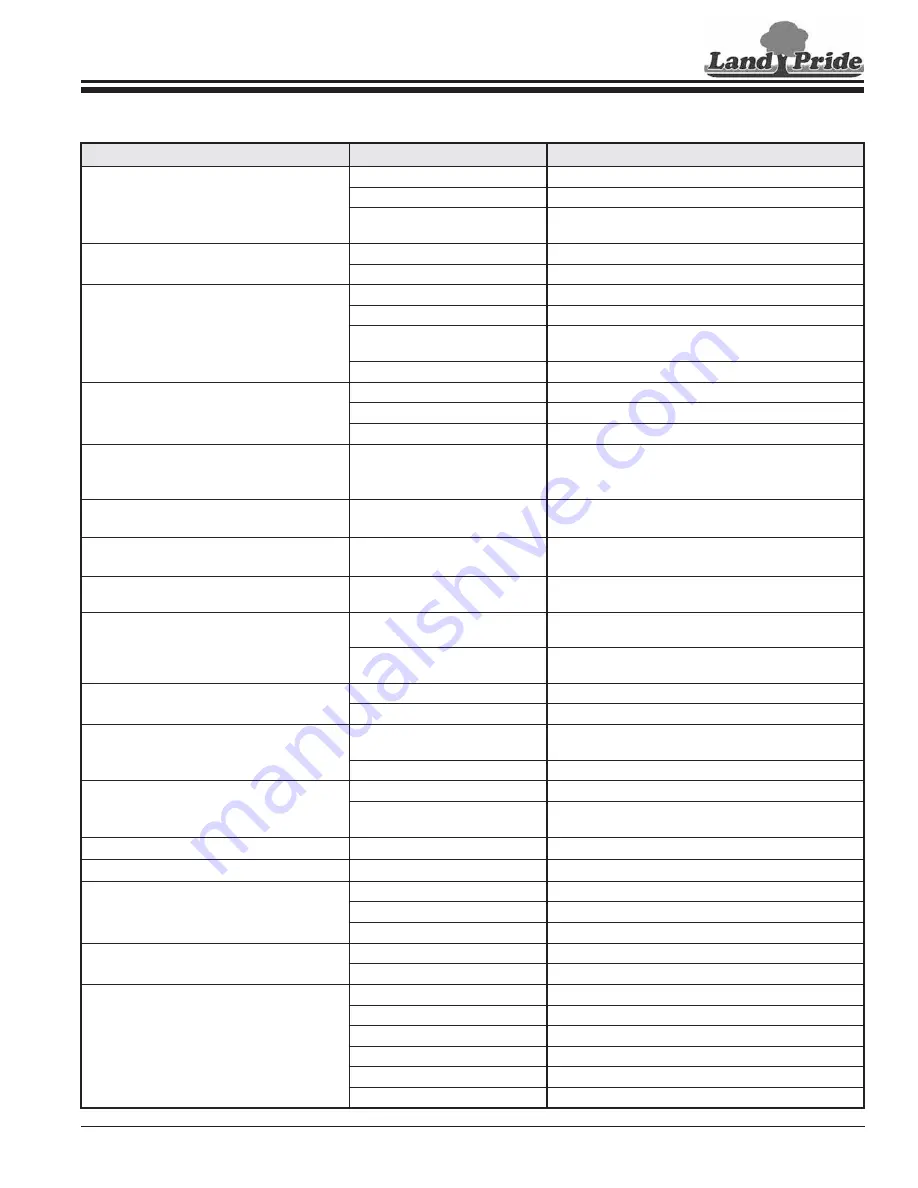

RCFM4014 Troubleshooting Chart

Problem

Cause

Solution

Oil seal leaking

Gearbox overfilled

Drain to bottom of side plug hole

Seals damaged

Replace seals

Grass or wire wrapped on shaft

in seal area

Check seal areas daily

Driveline yoke or cross failing

Shock load

Avoid hitting solid objects

Needs lubrication

Lubricate every 8 hours

Driveline clutch is slipping

Scalping the ground

Raise cutting height

Cutting too fast

Reduce travel speed

power take-off being engaged

too fast at high engine rpm

Slowly engage power take-off at low engine rpm

Cutting over solid objects

Avoid solid objects

Bent Driveline (NOTE: driveline should

be repaired or replaced if bent)

Contacting frame

Reduce lift height in transport position

Contacting drawbar

Reposition drawbar

Bottoming out

Shorten driveline

Driveline

telescoping tube failing

Shock load

Avoid hitting solid objects

Driveline

telescoping tube wearing

Needs lubrication

Lubricate every 40 hours

See “Intermediate Driveline Profile” on page 47

Shaft clamping cotter bolt on

intermediate driveline is not tight

Not maintaining intermediate

driveline

Re-tighten shaft clamping cotter bolt every 40

hours. See “Intermediate Drivelines” on page 38

Shaft clamping cotter bolt is shearing

Not greasing telescoping tubes Grease telescoping tubes every 40 hours.

See “Intermediate Drivelines” on page 38

Blades wearing excessively

Cutting on

sandy ground

Raise cutting height

Contacting

ground frequently

Raise cutting height

Blades breaking

Hitting solid objects

Avoid hitting solid objects

Blades hitting each other

Blade carriers need to be timed

Blades coming loose

Blades not

tightened properly

Tighten blade hardware.

Refer to “Service Cutting Blades” on page 34.

Improper deck attitude

Lower front of deck, see page 26.

Blade carrier becomes loose

Running loose in the past

Replace gearbox output shaft and blade carrier

Blade carrier hardware not tight

enough

Tighten to specified torque

Blade bolt holes worn

Blade hardware running loose

Replace blades and blade bolts if worn

Blade carrier bent

Hitting solid objects

Avoid hitting solid objects and replace blade carrier

Excessive side skid wear

Cutting height not level

Adjust cutter height

Soil abrasive

Adjust cutter height

Cutting too low

Adjust cutter height

Tail wheel support failing

Lowering too fast

Adjust rate of drop

Hitting objects when turning

Reduce speed on turns

Excessive vibration

Driveline bent

Replace driveline

Blades loose

Tighten blade bolts

Blade carrier bent

Replace blade carrier

Blade broken

Replace blades in sets

Blade will not swing

Remove and inspect blade

Blades have unequal weight

Replace both blades