Section 5: Maintenance & Lubrication

RCF2784 & RCR2684 S/N Rotary Cutters 326-364M

7/26/19

41

Lubrication Points

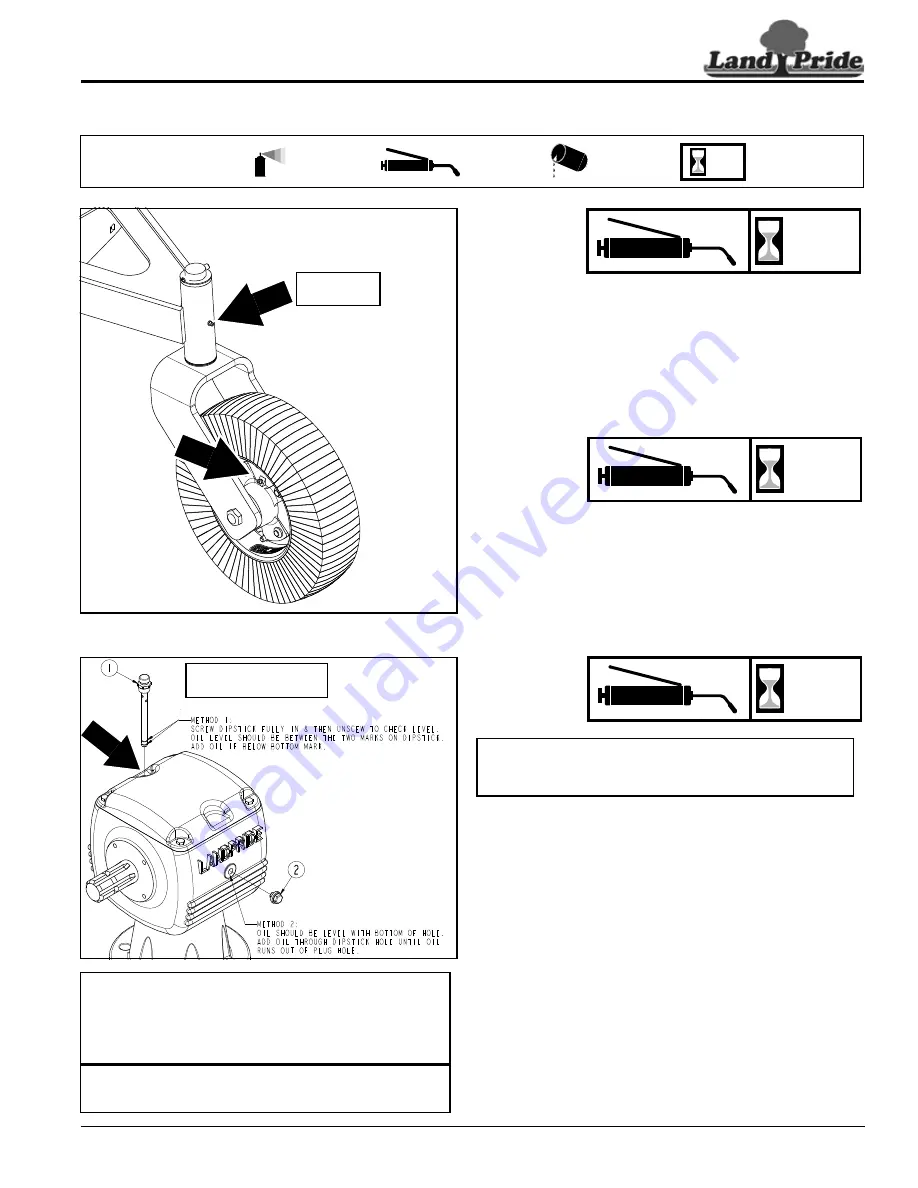

Gauge Wheel Spindle Tube (3-Point Cutters)

Type of Lubrication: Multi-purpose Grease

Quantity = 6 pumps

Gauge Wheel Hub

Type of Lubrication: Multi-purpose Grease

Quantity = 2 pumps

Gearbox

Method 1:

Unscrew top vented dipstick (#1). Wipe oil from

dipstick and screw dipstick in without tightening. Unscrew

dipstick and check oil on dipstick. If below bottom level

mark, add recommended gear lube through dipstick hole

until oil reaches top mark on dipstick. Reinstall vented

dipstick and tighten.

Method 2:

Remove side oil plug (#2). If oil is below bottom

of plug hole, add recommended gear lube through top

dipstick hole until oil flows out of side plug hole. Reinstall

and tighten side oil plug (#2) and vented dipstick (#1).

Type of Lubrication: 80-90W EP Gear Lube

Quantity = Fill until oil reaches top mark on dipstick or

begins to flow out side plug hole in gearbox.

NOTE:

Do not overfill! Cutter should be level when

checking oil. Oil expands when hot, therefore, always

check oil level when cold.

24

Hours

8

Hours

8

Hours

50

Hrs

Multi-purpose

spray lube

Multi-purpose

grease lube

Multi-purpose

oil lube

Intervals in hours at which

lubrication is required

Lubrication

Legend

33035

On 3-Point

Cutters Only

30215

Do Not Overfill

IMPORTANT:

This implement is shipped with a

NOTE:

Use a suction or siphon pump to drain

gearboxes of oil when there is not an oil drain plug.