Section 1: Assembly & Set-Up

RTR0542 & RTR0550 Rotary Tillers 311-464M

3/2/22

13

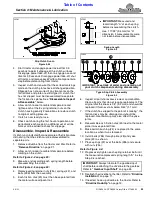

Park Stand in Transport Position

Figure 1-6

2. Remove wire retaining pin (#2) and parking

stand (#1).

3. Invert park stand (#1) upside down and reinsert it in

park stand mounting bracket (#3) as shown. Secure

park stand with wire retaining pin (#2).

3-Point Hitch Checks

1. Ensure that the lower arms are blocked to prevent

excessive side movement.

2. Slowly raise tiller with tractor hydraulics until the tines

are 1" to 2

"

(2.5 to 5 cm) above ground.

3. Adjust the tractor's lower lift arms to level the tiller

from left to right.

Final leveling adjustments will be

made in

the Adjustment Section on page 20.

4. Adjust the top-link so that the tiller is approximately

level from front to rear.

Final leveling adjustments

will be made in

the Adjustment Section on page 20.

5. Slowly operate the tractor's 3-Point hydraulic control

up and down to check for clearance between the

tires, frame, drawbar etc.

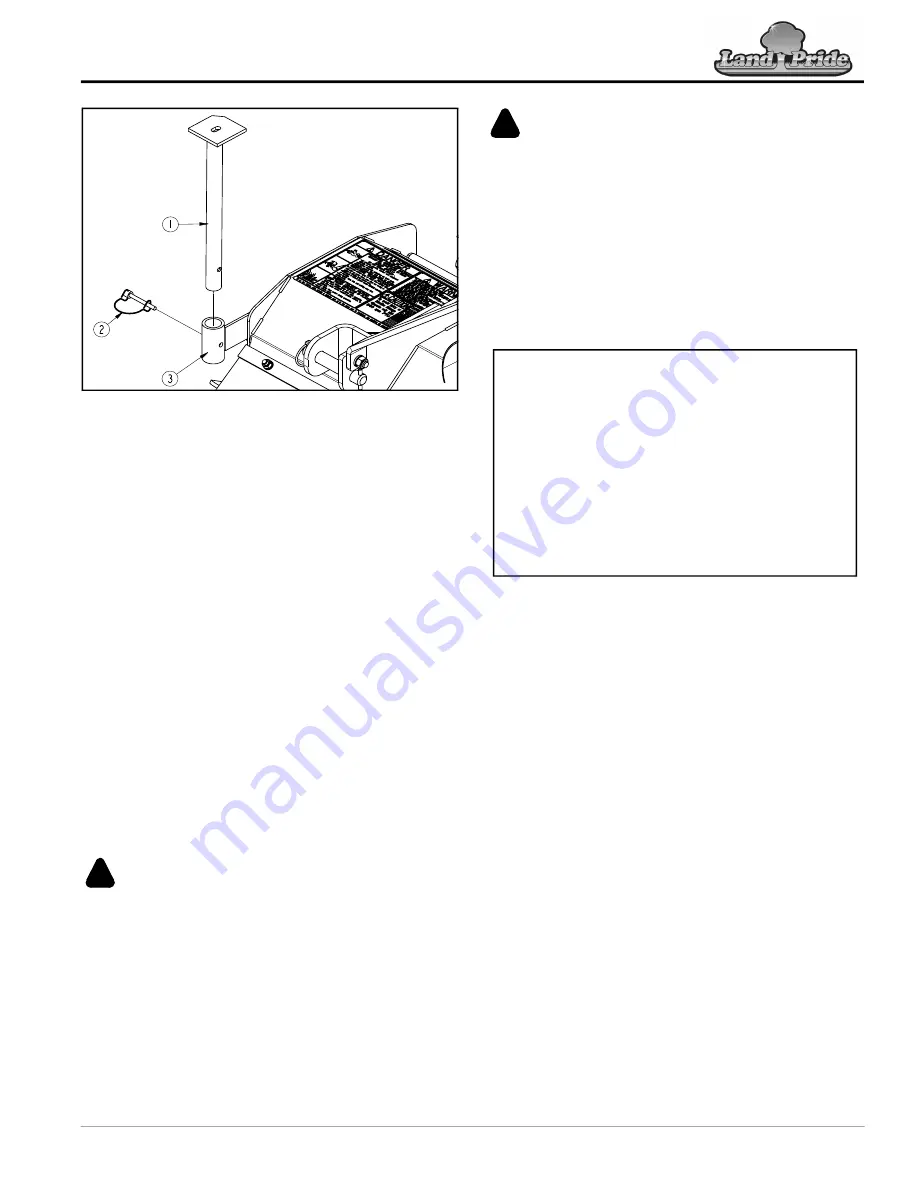

Driveline Hook-Up

Refer to Figure 1-5:

DANGER

!

To avoid serious injury or death:

•

Do not engage power take-off while hooking-up or

unhooking the driveline, or while someone is standing near

the driveline. A person’s body and/or clothing can become

•

All guards and shields must be installed and in good

working condition while operating the implement.

•

Do not use a power take-off adapter. The adapter will

increase strain on the tractor’s power take-off shaft causing

possible damage to shaft and driveline. It will also defeat

the purpose of the tractor’s power take-off shield.

23794

WARNING

!

To avoid serious injury or death:

•

Always follow “Tractor Shutdown Procedure” provided in

this manual before dismounting the tractor.

•

Select a safe ground speed that will allow adequate control

of steering and stopping. Never exceed 20 mph (32 km/h)

with attached equipment. Rough terrain requires a slower

•

Check driveline when lowering tiller into the ground to

make sure it does not interfere with the tractor drawbar at

maximum depth. If needed, shut tractor off and move or

remove drawbar to prevent damage to the driveline.

The driveline (#3) fastens to the tractor power take-off

shaft with a pull collar yoke (#4).

1. If driveline collapsible length has not been checked,

go to

“Check Driveline Collapsible Length”

page 14. Otherwise, continue with step 2 below.

2. Park tractor and implement on a level surface.

3. Shut tractor down before dismounting. Refer to

4. If tractor drawbar interferes with the driveline during

hook-up, disconnect driveline and move drawbar

forward, to the side, or remove.

5. Pull back on driveline pull collar (#4) and push the

driveline yoke onto the tractor’s power take-off shaft.

Release pull collar and continue to push the driveline

yoke forward until the pull collar pops out and locks in

place.

6. Pull on both ends of the driveline to make sure it is

secured to the tractor and implement.

7.

“Check Driveline Interference”

IMPORTANT:

An additional driveline may be

required if implement is attached to more than one

tractor or if a Quick Hitch is used.

IMPORTANT:

Drivelines with friction clutches must

go through a “run-in” prior to initial use and after long

periods of inactivity. For detailed instructions, see

IMPORTANT:

Check driveline collapsible and

maximum length before completing

. Structural damage to the equipment can