28

RTR0542 and RTR0550 Rotary Tillers 311-464M

11/01/11

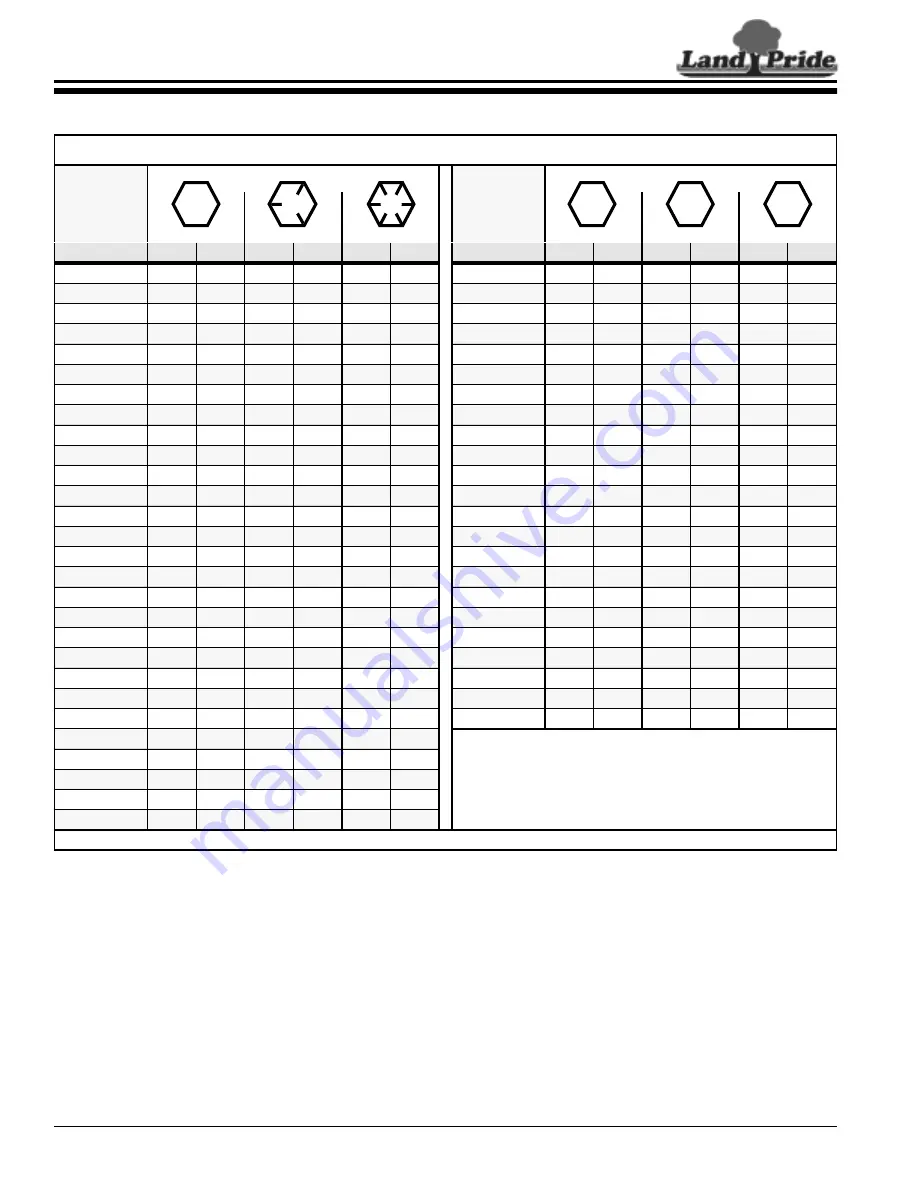

Section 8: Torque Values Chart

Table of Contents

Section 8: Torque Values Chart

Torque Values Chart for Common Bolt Sizes

in-tpi

1

N·m

2

ft-lb

3

N·m

ft-lb

N·m

ft-lb

mm x pitch

N·m

ft-lb

N·m

ft-lb

N·m

ft-lb

1/4" - 20

7.4

5.6

11

8

16

12

M 5 X 0.8

4

3

6

5

9

7

1/4" - 28

8.5

6

13

10

18

14

M 6 X 1

7

5

11

8

15

11

5/16" - 18

15

11

24

17

33

25

M 8 X 1.25

17

12

26

19

36

27

5/16" - 24

17

13

26

19

37

27

M 8 X 1

18

13

28

21

39

29

3/8" - 16

27

20

42

31

59

44

M10 X 1.5

33

24

52

39

72

53

3/8" - 24

31

22

47

35

67

49

M10 X 0.75

39

29

61

45

85

62

7/16" - 14

43

32

67

49

95

70

M12 X 1.75

58

42

91

67

125

93

7/16" - 20

49

36

75

55

105

78

M12 X 1.5

60

44

95

70

130

97

1/2" - 13

66

49

105

76

145

105

M12 X 1

90

66

105

77

145

105

1/2" - 20

75

55

115

85

165

120

M14 X 2

92

68

145

105

200

150

9/16" - 12

95

70

150

110

210

155

M14 X 1.5

99

73

155

115

l215

160

9/16" - 18

105

79

165

120

235

170

M16 X 2

145

105

225

165

315

230

5/8" - 11

130

97

205

150

285

210

M16 X 1.5

155

115

240

180

335

245

5/8" - 18

150

110

230

170

325

240

M18 X 2.5

195

145

310

230

405

300

3/4" - 10

235

170

360

265

510

375

M18 X 1.5

220

165

350

260

485

355

3/4" - 16

260

190

405

295

570

420

M20 X 2.5

280

205

440

325

610

450

7/8" - 9

225

165

585

430

820

605

M20 X 1.5

310

230

650

480

900

665

7/8" - 14

250

185

640

475

905

670

M24 X 3

480

355

760

560

1050

780

1" - 8

340

250

875

645

1230

910

M24 X 2

525

390

830

610

1150

845

1" - 12

370

275

955

705

1350

995

M30 X 3.5

960

705

1510

1120

2100

1550

1-1/8" - 7

480

355

1080

795

1750

1290

M30 X 2

1060

785

1680

1240

2320

1710

1 1/8" - 12

540

395

1210

890

1960

1440

M36 X 3.5

1730

1270

2650

1950

3660

2700

1 1/4" - 7

680

500

1520

1120

2460

1820

M36 X 2

1880

1380

2960

2190

4100

3220

1 1/4" - 12

750

555

1680

1240

2730

2010

1

in-tpi = nominal thread diameter in inches-threads per inch

1 3/8" - 6

890

655

1990

1470

3230

2380

2

N· m = newton-meters

1 3/8" - 12

1010

745

2270

1670

3680

2710

3

ft-lb= foot pounds

1 1/2" - 6

1180

870

2640

1950

4290

3160

4

mm x pitch = nominal thread diameter in millimeters x thread

pitch

1 1/2" - 12

1330

980

2970

2190

4820

3560

Torque tol 0%, -15% of torquing values. Unless otherwise specified use torque values listed above.

Grade 2

Grade 5

Grade 8

Bolt Head Identification

Bolt Size

(Inches)

Class 5.8

Class 8.8

Class 10.9

Bolt Head Identification

Bolt Size

(Metric)

5.8

8.8

10.9