Section 2: Operating Instructions

2/10/21

22

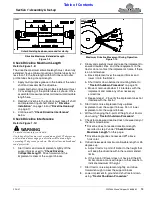

Slow Moving Vehicle Sign

Figure 2-2

Slow Moving Vehicle Sign

(Accessory)

Refer to Figure 2-2:

Land Pride offers the slow moving vehicle sign (#1) as an

accessory should your tractor not be equipped with a

removable sign that fits Land Pride’s SMV mounting

socket (#4). Also, mounting components (#2, #3, & #4)

can be purchased from your nearest Land Pride dealer

should you want to mount this sign on other equipment.

Item Part No.

Description

1

316-362S SMV Sign

2

802-092C RHSNB 5/16-18X3/4 GR5

3

803-177C NUT HEX FLG TP LK 5/16-18ZNYCR

4

890-401C SMV MOUNTING SOCKET

Detailed Operating Instructions

WARNING

!

To avoid serious injury or death: Allow only persons to

operate this implement who have fully read and

comprehended this manual, who have been properly trained in

the safe operation of this implement, and who are age 16 or

older. Serious injury or death can result from the inability to

read, understand, and follow instructions provided in this

The WC1504 Wood Chipper is designed to cut wood

products 4" in size and smaller such as brush, branches,

small trees, and lumber into small chips that can be

quickly turned into mulch or just to aid in decomposition.

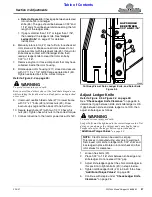

1. Park tractor with Wood Chipper outside on a level

solid surface. Make sure there is room to discharge

chips into a pile directed away from people, animals,

tractor, equipment, buildings, and operator.

2. Set tractor engine speed at an idle, place tractor gear

selector in park, and set park brakes.

3. Adjust skid extensions to support the Wood Chipper

at a height that will allow the driveline to operate as

level as possible. See

page 24 for detailed instructions.

37431

4. Lower Wood Chipper slowly onto its skid extensions.

5. Rotate discharge chute to discharge product in the

direction desired. See

page 25 for detailed instructions.

6. Rotate deflector chute to direct product being

discharged closer or farther away. See

on page 25 for detailed instructions.

7.

With engine speed at a low idle, engage

power take-

off and then slowly increase engine speed to

540 rpm.

8. Untangle product before inserting it into the feed

chute. Slowly slide one piece at a time into the feed

chute toward the rotor knives.

9. To protect oneself, do not reach past the rubber skirt

inside the feed chute. Instead use a stick or branch to

lightly push on the product as needed.

10. If tractor engine starts to slow, stop pushing on the

product. Once engine speed returns, continue push

lightly on product but at a slower speed.

Do not force

feed product into the chipper.

11. Once Wood Chipper starts to self-feed, release

product and allow rotor knives to pull product in at its

own speed. If knives will not pull product in, then refer

to

“Product self-feeds slowly or won’t self-feed at

in the

chart on page 37.

12. Make any necessary corrections to the discharge

chute angle and deflector chute to finalize direction

and location of chip pile.

13. Never leave Wood Chipper with unit running. Always

lower engine speed to an idle, disengage power take-

off, shut tractor engine off and remove switch key

before leaving the work area.

14. Disengage power take-off if foreign material such as

glass, metal, or rocks enters the chipper or if other

emergencies arise. Shut tractor engine off, remove

switch key, and wait for moving parts to come to a

complete stop before removing foreign material.

Inspect and make repairs before putting machine

back into service.

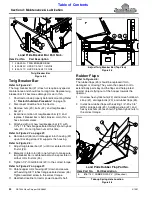

Helpful Operating Hints

The following hints will help keep the chipper running.

1. Be careful not to feed too much product at once, feed

oversize product, feed wet product, or feed product

too fast. Doing so can plug the Wood Chipper.

2. Alternate leafy material with a non leafy hardwood

piece. Hard wood pieces help clean out leafy

material. Keep alternating leafy material with

hardwood pieces until leafy material is processed.

3. Let leafy branches dry for a couple weeks before

chipping them. Dry leaves will process better.

4. Maintaining 1/32" gap between ledger bar and rotor

knives will keep knives wiped off, prevent plugging,

allow product to feed better, and keep wood chipping.