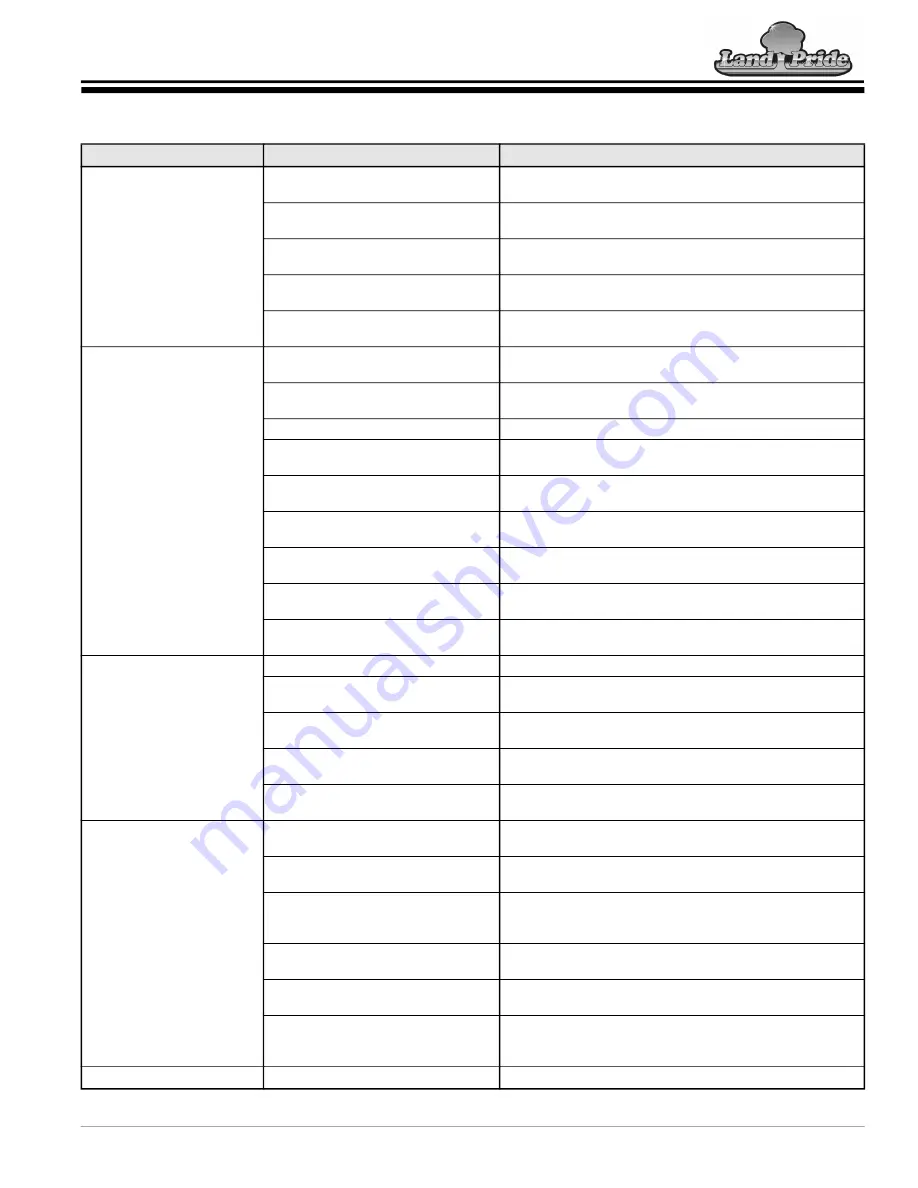

Section 7: Troubleshooting

2/10/21

37

Troubleshooting

Problem

Cause

Solution

Product self-feeds

slowly or won’t self-

feed at all

Rotor knives are worn

Rotate, sharpen, or replace rotor knives.

Tractor power take-off speed is below

540 rpm

Set tractor power take-off speed to 540 rpm.

Rotor knives are not sharpened at a

45

o

angle

Resharpen rotor knives to the proper angle.

Plugged rotor and/or discharge chute Clean discharge chute and rotor housing.

Clearance between rotor knife and

ledger knife is too large

Readjust ledger. See

Wood Chipper requires

excessive power to

operate, or stalls

Tractor horsepower is too low

Minimum 35 power take-off hp is required when operating

at maximum capacity.

Rotor knives are dull/worn

Rotate, sharpen, or replace rotor knives.

Overloading feed chute with product

Load feed chute with less product.

Loading feed chute with oversized

product

Feed only product 4" in diameter or smaller.

Product is too green or wet and sticks

to the internal surfaces.

Feed only dry product or alternate between dry and green

product to help keep internal surfaces clean.

Rotor housing is plugged

Clean rotor housing.

Discharge chute is plugged

Clean discharge chute.

Clearance between rotor knife and

ledger knife is too large

Readjust ledger. See

Ledger knife is dull/worn

Rotate ledger knife or replace ledger knife.

Rotor will not turn

Driveline is not engaged

Engage driveline.

Shear bolt in driveline is broken

Replace shear bolt.

Rotor housing is plugged

Clean rotor housing.

Rotor is plugged at the twig breaker

bar.

Clean Rotor around the twig breaker bar.

Bent twig breaker bar

Replace twig breaker bar.

Wood Chipper is

vibrating excessively

Loose rotor knife

Tighten rotor knife to rotor.

Broken or missing rotor knife

Replace broken or missing rotor knives in pairs.

Rotor knives don’t weigh the same

Re-sharpen the heaver rotor knife to remove material from

it until all rotor knives are the same.

Debris & dirt lodged in rotor

Clean rotor.

Bent rotor

Inspect straightness of rotor and rotor shaft. Replace as

rotor and/or rotor shaft if bent.

Bent twig breaker bar making contact

with rotor.

Replace twig breaker bar.

Driveline Vibrates

Worn Universal Joint

Replace Universal Joint.

Section 7:

Troubleshooting