Installation

Treadbelt Tracking

26

2.8.

Treadbelt Tracking

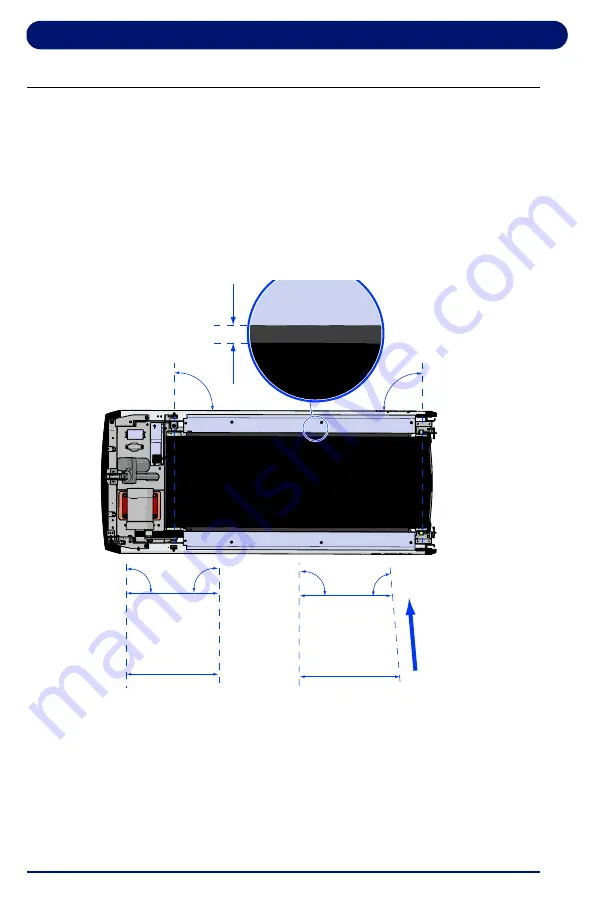

1. Ensure that the Treadbelt tracks properly. Treadbelt tracking is

maintained by ensuring that the drive and take-up rollers are

parallel, each is at right angles to the frame, so that the treadbelt

tension from side to side is equal as shown in the following figure. If

the treadbelt is running diagonally, with unequal gaps between the

treadbelt and sides then the rollers must be adjusted (see Figure 2-

30).

Figure 2-30. Tracking Setup

Adjustment is performed using the two adjustment screws (6mm

Allen wrench) located at rear of treadmill, see Figure 2-30. The

following provides a tracking adjustment example: Treadbelt tracks

to the right:

90°

90°

Belt tension equal

on both sides

90°

90°

90°

<90°

Belt tension

greater on left

side

Belt tension, right side

Belt tension, left side

Belt tension, right side

Belt tension, left side

Treadbelt to side gap.

Check both sides,

front and rear.

Belt forced to

the right side,

belt running

diagonally,

gaps unequal

from front to

rear.

Belt

running

true due

to equal

belt

tension.

Front,

drive

roller

Rear, take-

up roller