4-11 TIRE MAINTENANCE

4-11.1

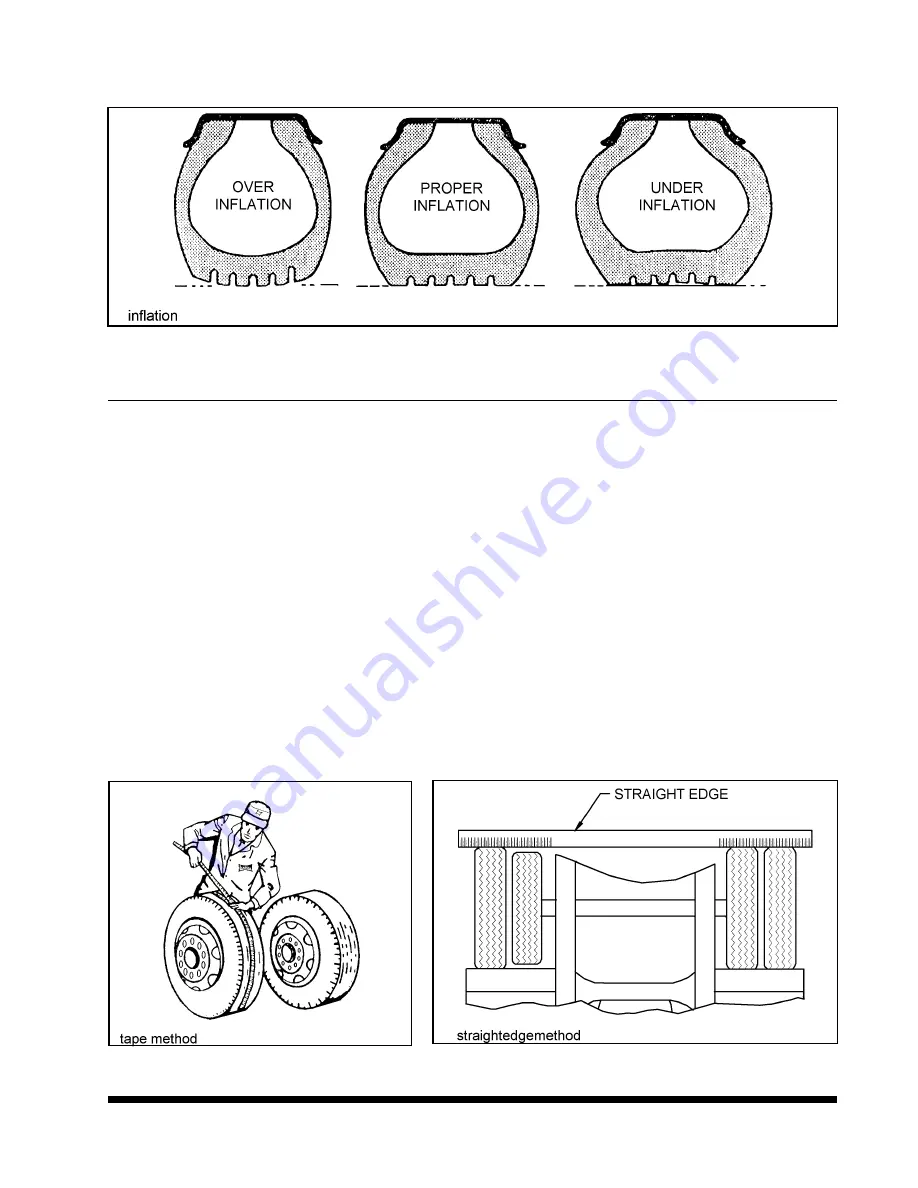

Tire Inflation

. Tire inflation will cause

tire to ground contact characteristics as

shown in

Figure 4-13

. Tire inflation should

be checked daily while the tire is cold, and

during road stops. Checking the tire pres-

sures while tires are hot will give a faulty in-

creased pressure reading. Adjusting tire air

pressure to the specified amount while tires

are hot will produce improper tire to road

contact and thus abnormal wear. Do not ex-

ceed cold inflation pressure listed on the

semitrailer VIN plate located on the front of

the trailer. Exceeding cold inflation pressure

will result in damaged tire bodies, rims, and

wheels. Replace all valve stem caps when

pressure checking/adjusting has been com-

pleted. Remove any foreign objects from be-

tween duals.

4-11.2

Tire Matching

. Both tires on the same

spindle must be the same size in order to

properly distribute the load and braking forces

between them. The tire must be mounted on a

rim and properly inflated before measuring. If

there is an allowable difference in size the

smaller tire should be mounted to the inside

position of the duals.

a. Tape Measuring Method

: Measure around

each tire on the tread surface. A maximum

difference of 3/4" is allowed between the two

mating tires of a dual

(See Figure 4-14).

b. Straight Edge or String Method

: (This

method cannot be used if tire and wheel as-

semblies are not mounted on the axle.) Jack

trailer up until the wheels are off of the

ground. Hold a straight edge against the tires

of both ends of an axle. A gap at one tire indi-

cates a smaller tire. A maximum of 1/8" gap is

allowed

(See Figure 4-15)

.

4-25

Figure 4-13 Tire Inflation Examples

Figure 4-14 Measuring Tape Method

Figure 4-15 Straight Edge Method

Summary of Contents for 317C

Page 8: ......

Page 14: ...3 2 Figure 3 1 Front Trailer Terminology Figure 3 2 Rear Trailer Terminology...

Page 18: ......

Page 24: ...3 12 Figure 3 5 Steps for Loading and Unloading...

Page 30: ...3 18 Figure 3 10 Dock Leveler Operation...

Page 34: ...3 22 Figure 3 12 Front Extension Bulkhead...

Page 36: ...3 24 Figure 3 13 Rear Impact Guard and Antilock Brake System...

Page 40: ...4 2 Figure 4 1 Lubrication Points...

Page 45: ...4 7 Figure 4 2 317C 318C 319C Wiring Diagram...

Page 46: ...4 8 Figure 4 3 Remote Wiring Diagram...

Page 52: ...4 14 Figure 4 6 Checking Axle Alignment Figure 4 7 Examples of Camber...

Page 56: ...4 18 Figure 4 10 Axle and Brake Assembly...

Page 64: ...4 26 Figure 4 16 Mounting Tires and Wheels Figure 4 17 Stud Tightening Sequence...

Page 67: ...4 29 Figure 4 18 Dock Leveler Leg Assembly...

Page 68: ......

Page 78: ...5 10 NOTES...