4-7

ALIGN MENT

4-7.1

Wheel Align ment

DAN GER

TO PRE

VENT A LIFE THREAT

EN

ING

AC CI DENT:

1. SUP

PORT TRAILER AND UN

DER

-

CAR

RIAGE SO TIRES ARE OFF THE

GROUND.

2. SUP

PORT THE TRAILER AND UN

-

DER

CAR

RIAGE ON JACK STANDS

WITH SUF FI CIENT CA PAC ITY TO SUP -

PORT THE TO

TAL WEIGHT OF THE

TRAILER AND ANY LOAD WHICH IT

MAY BE CAR RY ING.

When trailer tires show signs of scuff

ing,

feather- edging or un even wear, ex am ine the trailer

for dam

aged sus

pen

sion (frame, shocks, link

age,

etc.), axle, wheel bear

ings and wheels. Proper

wheel align

ment and wheel bear

ing ad

just

ment is

es sen tial for proper tire wear. The sim plest form of

check

ing wheel align

ment “toe” is by run

ning the

trailer over a “SCUFF GAUGE”. A scuff gauge

read

ing of 16 feet or less per mile is con

sid

ered

sat

is

fac

tory. If a scuff gauge is not read

ily avail

-

able, or edge wear on one side of a tire is oc cur -

ring sig ni fy ing posi tive or nega tive cam ber, align -

ment can be checked as fol lows:

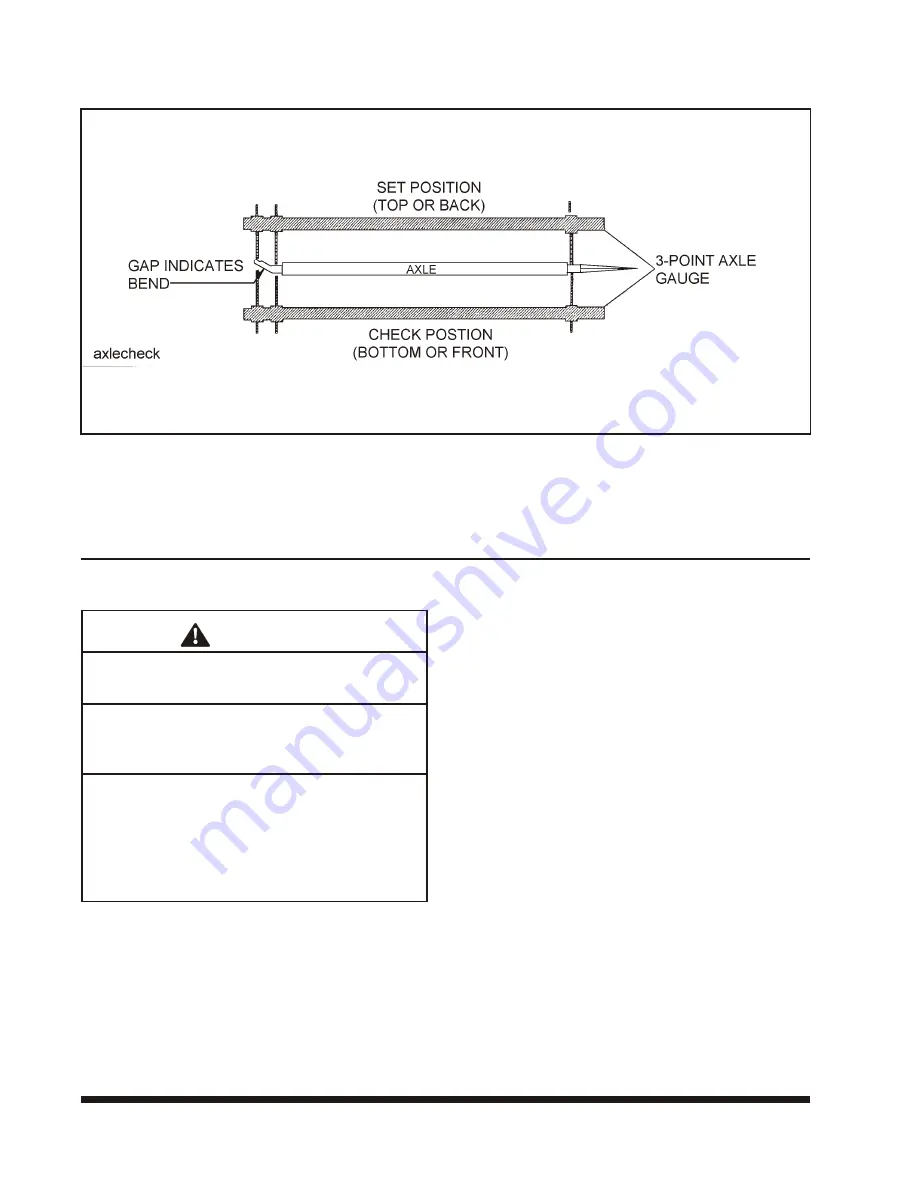

a.

Re

move wheel, hub and bear

ing as

sem

-

blies.

b.

Place a 3- point axle gauge against the front

side of the axle, and ad just each axle gauge

point to the axle. (Dou

ble point end against

the in ner and outer wheel bear ing sur faces of

the spin dle be ing checked and the other point

on the in

ner bear

ing sur

face on the other

spin dle.)

(See Fig ure 4-5).

c.

Move the axle gauge and place against the

back side of the axle. If ei ther of the points of

dou ble point end fails to touch the axle sur -

face, a bent spin dle is evi dent. A point gap of

.015" or more is con

sid

ered ex

ces

sive tire

“toe” and the axle must be re placed

(See Fig -

ure 4-5)

.

4-12

FIG URE 4-5 CHECK ING AXLE FOR BEND

Summary of Contents for 318C

Page 3: ...MODELS 318C BOEING TRAILER OPERATOR S MANUAL PURCHASED FROM DATE ADDRESS PHONE NO SERIAL NO i...

Page 8: ......

Page 12: ......

Page 32: ...3 20 FIGURE 3 6 STEPS FOR LOADING AND UNLOADING...

Page 36: ...3 24 FIGURE 3 8 REAR IMPACT GUARD AND ANTILOCK BRAKE SYSTEM...

Page 52: ...4 14 FIGURE 4 6 CHECKING AXLE ALIGNMENT FIGURE 4 7 EXAMPLES OF CAMBER...

Page 56: ...4 18 FIGURE 4 10 AXLE AND BRAKE ASSEMBLY...

Page 64: ...4 26 FIGURE 4 16 MOUNTING TIRES AND WHEELS FIGURE 4 17 STUD TIGHTENING SEQUENCE...

Page 76: ...5 10 NOTES...