4-6.2

Periodic Maintenance of the Gooseneck

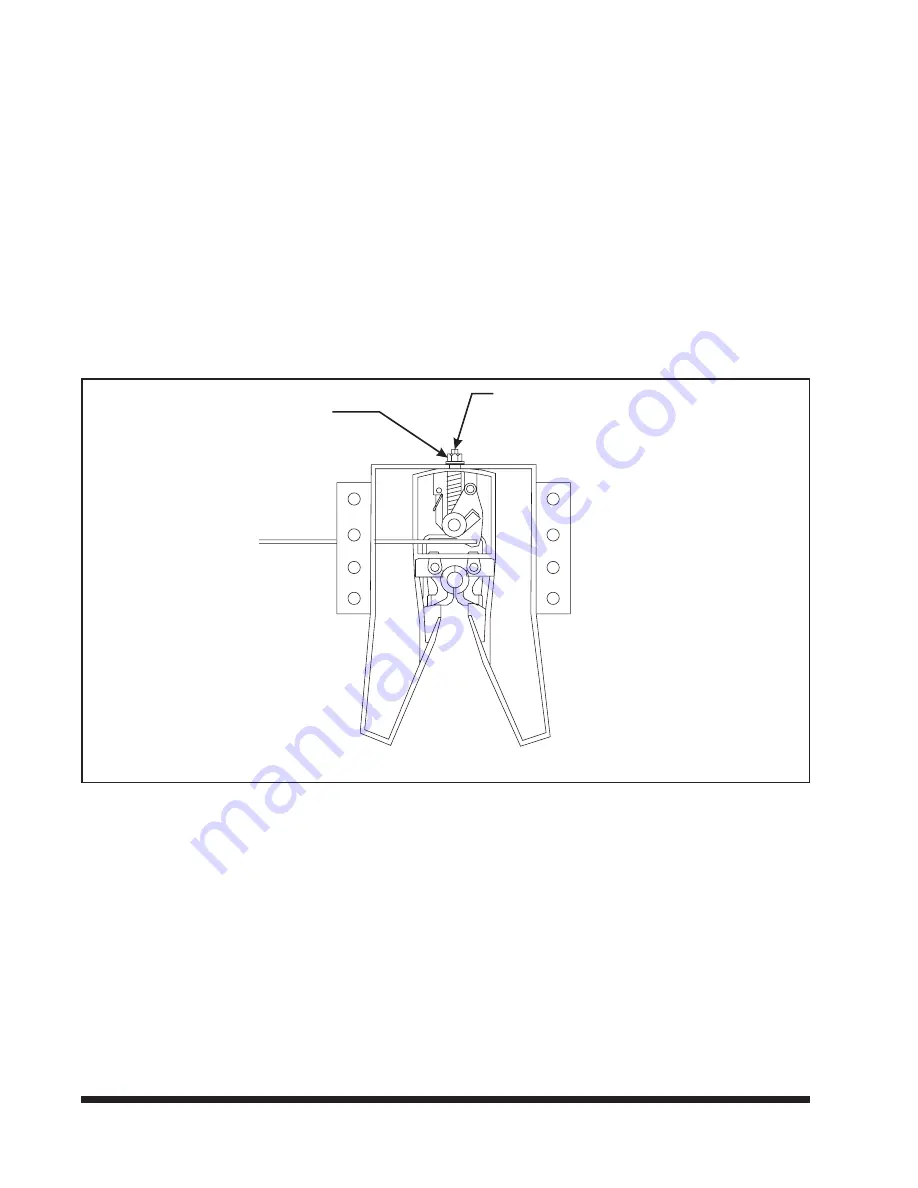

Lock Mechanism:

a.

The gooseneck lock mechanism should be

inspected and adjusted as necessary or every

30,000 miles. The inspection should include a

check for cracks in the top plate, elongated

attachment holes, and excessive wear or fail-

ure of component parts. Any defective parts

must be replaced before the lock mechanism

is used.

b.

Close the locks and insert a 2"

"

.005 plug in

the locks.

c.

Check for a tight fit. The plug should be

snug, but you should be able to rotate it by

applying some force.

d.

If the plug fits loosely, tighten by rotating the

nut on the shank counterclockwise. It may be

necessary to tap the end of the yoke shank

lightly to allow the nut to seat against the top

plate

(See Figure 4-5).

e.

Repeat this procedure until the plug fits

snug, but can still be rotated.

f.

Use a lock tester to verify the proper opera-

tion of the locking mechanism.

4-10

YOKE SHANK

NUT

YOKE SHANK

fifth wheel adjustment

Figure 4-5 Fifth Wheel Adjustment

Summary of Contents for 325C

Page 2: ......

Page 8: ......

Page 12: ......

Page 36: ......

Page 44: ...4 8 Figure 4 3 Models 325 326 327 329C Wiring Diagram...

Page 54: ...4 18 Figure 4 13 Checking Axle Alignment Figure 4 14 Examples of Camber...

Page 59: ...4 23 Figure 4 17 Axle and Brake Assembly...

Page 68: ......

Page 78: ...NOTES 5 10...

Page 79: ......