4-6.3

Gooseneck Lock Rebuilding Procedure:

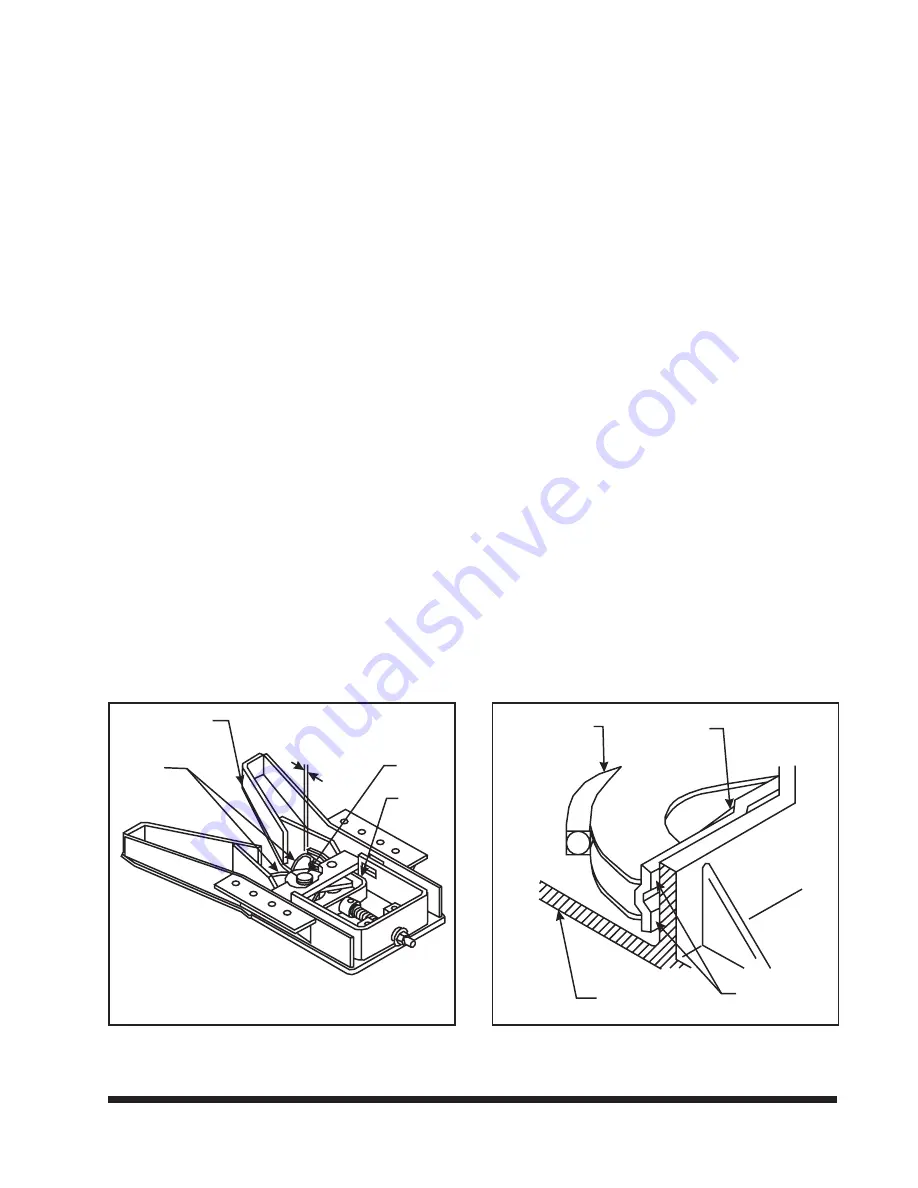

Refer to

Figure 4-8

for parts identification and

proper parts orientation.

a.

Disassemble the lock and inspect the top

plate for cracks or elongated holes. Cracked

top plates must be discarded, but a top plate

with elongated holes may be rebuilt after

building the holes up and reboring them.

b.

Lubricate the lock pin holes with Neverseez

or its equivalent.

c.

Insert the lock jaws into the top plate with

the 2-7/8" bore toward the face of the top

plate.

d.

Drive the lock pins through the top plate and

the lock jaw pin holes until the lock pins are

flush with the face of the top plate.

e.

Secure the lock pins with cotter pins.

f.

Check to be sure the lock jaws can move

freely and install a 2" diameter plug in the lock

jaws.

g.

The yoke must fit precisely for maximum

service life and proper lock function. Bend the

tips of the yoke slightly outward.

h.

Slide the yoke into the top plate with the

threaded hole in the yoke facing upward and

tap it into position.

i.

Check the position of the yoke tips. They

must be flush with the ends of the locks or

must not extend more than 1/32" beyond the

ends of the locks

(See Figure 4-6).

If the

yoke are short of the ends of the locks, it will

be necessary to grind the outside surfaces of

the yoke with a belt sander or grinder until it

fits precisely into place

(See Figure 4-6).

If

the yoke extends beyond the ends of the

locks, it will be necessary to build up the con-

tact surface of the yoke with weld using a low

hydrogen E70XX welding rod and grind the

surfaces back down to the proper fit

(See Fig-

ures 4-6 and 4-7).

IMPORTANT

NEVER GRIND OR WELD ON THE INSIDE SUR-

FACE OF THE YOKE OR ON THE LOCKS.

j.

There are two contact surfaces

(See Figure

4-7)

on the outside of each yoke tip. All four

surfaces must have full area contact with the

top plate ribs. Continue the weld, grind, and fit

process until the yoke has full contact and the

yoke tips are flush with the ends of the locks.

k.

Lube both the inside and outside friction

surfaces of the yoke and then slide it into the

top plate with the threaded hole facing up.

l.

Install the spring between the yoke and the

top plate. Insert the yoke shank through the

top plate, spring, and into the yoke. Make

sure that the predrilled recess in the yoke

shank aligns with the threaded hole in the

yoke.

4-11

TOP PLATE

LOCK

JAW

PLUG

YOKE

checking yoke position

0”

1/32

+

-

Figure 4-6 Checking Yoke Position

LOCK JAW

YOKE

TOP PLATE

CONTACT

SURFACE

yoke contact surfaces

Figure 4-7 Yoke Contact Surfaces

Summary of Contents for 325C

Page 2: ......

Page 8: ......

Page 12: ......

Page 36: ......

Page 44: ...4 8 Figure 4 3 Models 325 326 327 329C Wiring Diagram...

Page 54: ...4 18 Figure 4 13 Checking Axle Alignment Figure 4 14 Examples of Camber...

Page 59: ...4 23 Figure 4 17 Axle and Brake Assembly...

Page 68: ......

Page 78: ...NOTES 5 10...

Page 79: ......