4-7.3

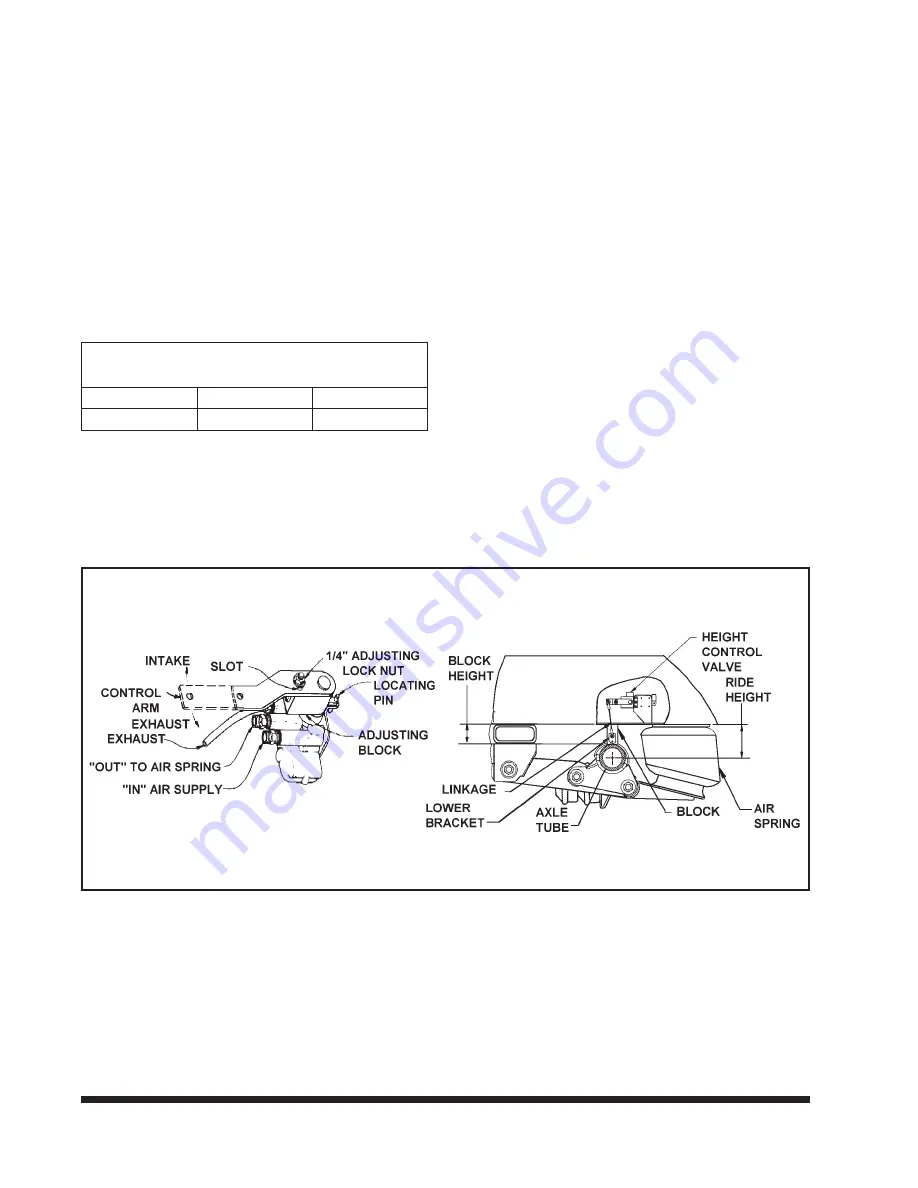

Air Ride Height Adjustment

.

(See Fig-

ure 4-11

for parts identification)

.

a.

Before adjusting, the vehicle must be empty

with the kingpin at operating height and have

air supplied to the trailer.

b.

Disconnect linkage at the control arm and

raise control arm to the “up” position, raising

the trailer until a block can be placed between

axle tube and undercarriage frame

(See Fig-

ure 4-11).

c.

Position the wood block between the axle

tube and frame according to table below.

Block height is dependent upon suspension

ride height and/or axle brake size.

AIR SUSPENSION

RIDE HEIGHT AND BLOCK

Brake Size

Ride Height

Block Height

16-1/2" Dia.

9"

6.5"

d.

Lower the trailer by exhausting air from the

air springs by moving the control arm to the

“down” position (about 45°) until the axle tube

is resting on the block.

e.

Check the ride height to make sure it is cor-

rect. Consult Landoll Service Center if correct

height cannot be obtained.

f.

Loosen the 1/4" adjusting lock nut located

on the adjusting block, allowing the control

arm to move approximately 1 inch. Move the

adjusting block until holes align, then insert

locating pin.

(See Figure 4-11)

.

g.

Align the control arm linkage to the control

arm lower bracket and re-tighten the 1/4" ad-

justing lock nut to 2-4 ft.lbs. The ride height

valve should now be correctly adjusted.

h.

Remove the locating pin.

i.

The block can now be removed by using the

height control valve as an improvised jack by

disconnecting the control arm at the lower

bracket and pushing the control arm to an

“up” position.

j.

Remove the block and reconnect the link-

age. This allows the Automatic Height Control

Valve to resume normal operation.

k.

Check the air ride height. If necessary, go

through the adjustment procedure again until

the proper air ride height is achieved.

l.

Check the air ride height periodically and

adjust as needed.

4-16

Figure 4-11 Air Ride Height Adjustment

Summary of Contents for 325C

Page 2: ......

Page 8: ......

Page 12: ......

Page 36: ......

Page 44: ...4 8 Figure 4 3 Models 325 326 327 329C Wiring Diagram...

Page 54: ...4 18 Figure 4 13 Checking Axle Alignment Figure 4 14 Examples of Camber...

Page 59: ...4 23 Figure 4 17 Axle and Brake Assembly...

Page 68: ......

Page 78: ...NOTES 5 10...

Page 79: ......