2.

Align the front axle using the method

outlined in

Section 4-8.2a.

3.

After proper alignment has been obtained,

tighten the suspension pivot bolt nut to the

torque listed in the table in

Section 4-7.1

4.

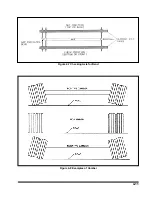

Align the rear axle to the front axle. Locate

the rear axle equalizer beam pivot bolt in

hanger at front end of driver’s side rear axle

equalizer beam. Loosen the suspension

pivot bolt lock nut. Rotate the head of the

pivot bolt. For axle alignment forward, rotate

bolt head clockwise. For axle alignment

rearward, rotate the bolt head

counter-clockwise. The rear axle should be

parallel with the front axle, with the

dimensions Y and Y1 being the same.

5.

Tighten the suspension pivot bolt nut to the

torque listed in the table in

Section 4-7.1

4-9 BRAKE SYSTEM MAINTENANCE

CAUTION

USE GREAT CARE IF WHEELS OR

BRAKE DRUMS MUST BE HANDLED.

THEY MAY BE VERY HOT AND CAN

CAUSE INJURY.

4-9.1

General

.

a.

Check air hoses for chafing, bends, kinks,

or damaged fittings. Replace defective hoses.

b.

Check the brake system for loose, missing,

deformed, or corroded fasteners. Replace

and tighten defective hardware.

c.

Check brake linings for excessive wear or

distortion.

d.

Drain air reservoir daily. A drain cock on the

bottom of each air reservoir vents the tank to

drain collected water and oil. If held open, air

pressure in the tanks is relieved, causing the

emergency or parking brakes to be applied

(See Figure 4-10).

4-9.2

Spring Air Brake

Check for faulty units. Check the condensation

holes on the underside of the brake chambers to

make sure they are open. The spring brake has

two brake chambers, a service chamber and and

an emergency chamber or spring chamber

(See

Figure 4-10).

Service brake chambers should be

disassembled and cleaned at 50,000 miles or

yearly. The diaphragm and any marginal parts

should be replaced. When replacing the service

diaphragm, replace the corresponding parts for the

other chamber on the same axle (to aid in even

brake application and release). Examine yoke pin

for wear and replace as necessary. The spring

chamber should not be serviced. Replace entire

unit (both service and spring chamber) if spring

chamber becomes faulty.

4-13

Figure 4-10 Drain Cock Locations

Summary of Contents for 336C

Page 3: ...MODEL 336C CAR CARRIER OPERATOR S MANUAL PURCHASED FROM DATE ADDRESS PHONE NO SERIAL NO...

Page 8: ......

Page 24: ...3 12 Figure 3 7 Lining Up the Over the Cab Deck Figure 3 8 Loading the Over the Cab Deck...

Page 28: ...3 16 Figure 3 11 Loading the Lower Deck...

Page 32: ...3 20 Figure 3 13 Rear Impact Guard and Antilock Brake System...

Page 40: ...4 6 Figure 4 3 336C Wiring Diagram...

Page 45: ...4 11 Figure 4 7 Checking Axle for Bend Figure 4 8 Examples of Camber...

Page 50: ...4 16 Figure 4 12 Axle and Brake Assembly...

Page 54: ...4 20 Figure 4 14 Outboard Mount Hub and Drum Figure 4 15 Inboard Mount Hub and Drum...

Page 59: ...4 25 Figure 4 19 Mounting Tires and Wheels Figure 4 20 Stud Tightening Sequence...

Page 70: ...NOTES 5 10...