4-8 ALIGNMENT

4-8.1

Wheel Alignment

DANGER

TO PREVENT A POTENTIALLY LIFE

THREATENING ACCIDENT:

1. SUPPORT SEMITRAILER AND UN-

DERCARRIAGE SO TIRES ARE OFF

THE GROUND.

2. SUPPORT THE SEMITRAILER AND

UNDERCARRIAGE ON JACK STANDS

WITH SUFFICIENT CAPACITY TO SUP-

PORT THE TOTAL WEIGHT OF THE

SEMITRAILER AND ANY LOAD WHICH

IT MAY BE CARRYING.

When semitrailer tires show signs of scuffing,

feather-edging or uneven wear, examine the semi-

trailer for damaged suspension (frame, shocks,

linkage, etc.), axle, wheel bearings and wheels.

Proper wheel alignment and wheel bearing adjust-

ment is essential for proper tire wear. The simplest

form of checking wheel alignment “toe” is by run-

ning the semitrailer over a “SCUFF GAUGE”. A

scuff gauge reading of 16 feet or less per mile is

considered satisfactory. If a scuff gauge is not

readily available, or edge wear on one side of a

tire is occurring signifying positive or negative cam-

ber, alignment can be checked as follows:

a.

Remove wheel, hub and bearing assem-

blies.

b.

Place a 3-point axle gauge against the front

side of the axle, and adjust each axle gauge

point to the axle. (Double point end against

the inner and outer wheel bearing surfaces of

the spindle being checked and the other point

on the inner bearing surface on the other

spindle

(See Figure 4-7).

c.

Move the axle gauge and place against the

back side of the axle. If either of the points of

double point end fails to touch the axle sur-

face, a bent spindle is evident. A point gap of

.015" or more is considered excessive tire

“toe” and the axle must be replaced

(See Fig-

ure 4-7)

.

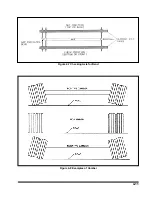

d.

Follow the same procedures as in

Section

, except place the axle gauge

above and below the axle. If gauge point gap

is found, the axle has positive or negative

camber. The semitrailer axle has no camber

from the factory. If it is found to have positive

or negative camber, axle replacement is nec-

essary

(See Figure 4-8

for examples of cam-

ber).

4-10

Figure 4-6 Air Ride Height Adjustment

Summary of Contents for 336C

Page 3: ...MODEL 336C CAR CARRIER OPERATOR S MANUAL PURCHASED FROM DATE ADDRESS PHONE NO SERIAL NO...

Page 8: ......

Page 24: ...3 12 Figure 3 7 Lining Up the Over the Cab Deck Figure 3 8 Loading the Over the Cab Deck...

Page 28: ...3 16 Figure 3 11 Loading the Lower Deck...

Page 32: ...3 20 Figure 3 13 Rear Impact Guard and Antilock Brake System...

Page 40: ...4 6 Figure 4 3 336C Wiring Diagram...

Page 45: ...4 11 Figure 4 7 Checking Axle for Bend Figure 4 8 Examples of Camber...

Page 50: ...4 16 Figure 4 12 Axle and Brake Assembly...

Page 54: ...4 20 Figure 4 14 Outboard Mount Hub and Drum Figure 4 15 Inboard Mount Hub and Drum...

Page 59: ...4 25 Figure 4 19 Mounting Tires and Wheels Figure 4 20 Stud Tightening Sequence...

Page 70: ...NOTES 5 10...