CAUTION

THE AUXILIARY (BLUE) CIRCUIT IS

FOR POWERING THE SEMITRAILER

ABS. THIS CIRCUIT MUST BE HOT

WHEN THE TRACTOR KEY SWITCH IS

ON. NO OTHER ELECTRICAL DEVICES

MAY BE POWERED BY THIS CIRCUIT

WHILE THE SEMITRAILER IS MOVING

FORWARD.

Malfunction in the ABS is signaled by illumina-

tion of the ABS warning lamp located at the left

rear side of the semitrailer. The warning lamp will

come on and stay on while power is supplied to

the ABS on a moving vehicle, if there is a fault. If a

fault in the ABS exists, normal braking will still oc-

cur, but wheels may lock. The semitrailer is still op-

erable, but the system should be serviced as soon

as possible.

CAUTION

IF A FAULT EXISTS IN THE SEMI-

TRAILER ABS, NORMAL BRAKING

WILL OCCUR, BUT WHEELS MAY

LOCK. SERVICE THE ABS AS SOON

AS POSSIBLE.

The ABS is also equipped with a Blink Code

Diagnostic Tool mounted at the right rear corner of

the undercarriage or at the very rear of the trailer.

This tool is used to identify faults that may occur in

the ABS so that they may be repaired.

Refer to ABS maintenance manual supplied

with trailer to answer basic questions for the anti-

lock brake system, obtain outline procedures on

how to adjust, test, remove, and install ABS com-

ponents, as well as how to test for faults in the

system by using “Blink Code Diagnostics”; and il-

lustrates ABS components, wiring, and plumbing

installation diagrams.

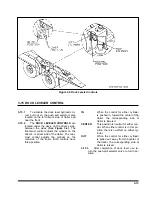

3-18 REMOTE OPERATION

3-18.1

The wired remote control plugs into an

electrical receptacle usually located by the

Hydraulic Control Panel. Optional receptacle

locations are on the rear street side or both

rear street and rear curb sides. The wired re-

mote is available as a single, dual, or triple

function.

(See Figure 3-8).

3-18.2

A wireless radio remote control is also

available as a dual, or triple function.

3-18.3

The remotes operate any of the hydrau-

lic functions that are desired. The remote

components are connected to the hydraulic

valve section that the remote is desired to

operate. The electrical switches operate the

functions of the hydraulic spool valve instead

of operating the control levers on the valve.

3-19 COLD WEATHER OPERATION

3-19.1

Cold weather causes lubricants to con-

geal, insulation and rubber parts to become

hard, which may lead to problems found in

bearings, electrical systems, and air systems.

Moisture attracted by warm parts can con-

dense, collect and freeze to immobilize

equipment. The truck/trailer operator must al-

ways be alert for indicators of cold weather

malfunctions.

3-19.2

During any extended stop period, nei-

ther the service nor parking brake should be

used as they can freeze up. Use wheel

chocks to secure the vehicle from moving.

3-19.3

Check all structural fasteners, air sys-

tem fittings, gaskets, seals and bearings for

looseness that can develop due to contrac-

tion with cold. Do not over-tighten.

3-19.4

Check tire inflation. Tire inflation de-

creases when the temperature decreases.

3-19.5

Periodically check drain holes in the bot-

tom of the relay valve (for trailers with air

brakes) and storage compartments. They must

be open at all times to avoid moisture en-

trapment.

3-16

Summary of Contents for 345B

Page 3: ...MODEL 345B TRAILER OPERATOR S MANUAL PURCHASED FROM DATE ADDRESS PHONE NO SERIAL NO ...

Page 8: ......

Page 12: ......

Page 22: ...3 10 Figure 3 4 Steps for Loading and Unloading ...

Page 26: ...3 14 Figure 3 7 Rear Impact Guard and Antilock Brake System ...

Page 30: ......

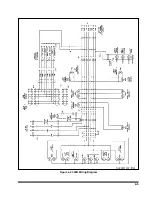

Page 35: ...4 5 Figure 4 2 345B Wiring Diagram ...

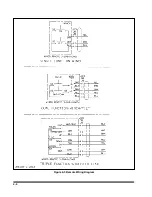

Page 36: ...4 6 Figure 4 3 Remote Wiring Diagram ...

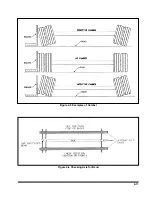

Page 41: ...4 11 Figure 4 5 Examples of Camber Figure 4 6 Checking Axle for Bend ...

Page 46: ...4 16 Figure 4 10 Axle and Brake Assembly ...

Page 50: ...4 20 Figure 4 13 Outboard Mount Hub and Drum Figure 4 14 Inboard Mount Hub and Drum ...

Page 54: ...4 24 Figure 4 18 Mounting Tires and Wheels Figure 4 19 Stud Tightening Sequence ...

Page 65: ...5 9 NOTES ...