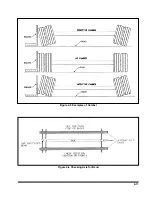

d.

Follow the same procedures as in

Section

except place the axle gauge

above and below the axle. If gauge point gap

is found, the axle has positive or negative

camber. The trailer axle has no camber from

the factory. If it is found to have positive or

negative camber, axle replacement is neces-

sary

(See Figure 4-5

for examples of cam-

ber).

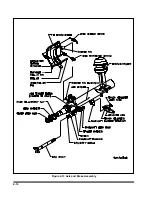

4-7.2

Axle Alignment

Proper axle to pintle eye alignment is neces-

sary to obtain straight tracking. If axle alignment is

off, “dog-tracking” occurs. Check alignment manu-

ally or by using a semitrailer alignment machine. In

either case, a thorough inspection of the complete

suspension must be performed and all defects cor-

rected before aligning.

a. Manual Alignment Procedure

1.

Position semitrailer on a firm and level

surface. Insure that the undercarriage is in

the rear most position. Eliminate any

suspension binding due to sharp turns or

unusual maneuvers.

2.

Detach tractor from the semitrailer and jack

the trailer up sufficiently to permit

measuring from the underside of the trailer.

3.

Suspend a plumb bob at axle height from

the center of the pintle eye.

4.

Measure (D) from the plumb bob to the

center point on one end of the axle. Record

this measurement

(See Figure 4-7

5.

Measure (D1) to the other end of the axle in

the same manner as in

Step 4.

. Record this

measurement

(See Figure 4-7).

6.

Set D about 1/8" shorter than D1 to insure

proper trailer tracking on slope of road.

7.

The suspensions must be in good repair

with no binding or other restrictions before

aligning. All defective parts of the

suspension or axles must be replaced

immediately.

b. Air Ride Suspension Axles

The air ride suspension is aligned and ad-

justed at the factory and it should not be necessary

to align the axles. If, however it does become nec-

essary to align the axles, the procedure is as fol-

lows:

1.

To align air ride suspension axles, locate

the front axle equalizer beam pivot bolt in

front hanger at front end of lock nut. Rotate

the head of the pivot bolt. For axle

alignment forward, rotate bolt head

clockwise. For axle alignment rearward,

rotate the bolt head counter-clockwise.

Loosen the suspension pivot bolt lock nut.

4-12

Figure 4-7 Checking Axle Alignment

Summary of Contents for 345B

Page 3: ...MODEL 345B TRAILER OPERATOR S MANUAL PURCHASED FROM DATE ADDRESS PHONE NO SERIAL NO ...

Page 8: ......

Page 12: ......

Page 22: ...3 10 Figure 3 4 Steps for Loading and Unloading ...

Page 26: ...3 14 Figure 3 7 Rear Impact Guard and Antilock Brake System ...

Page 30: ......

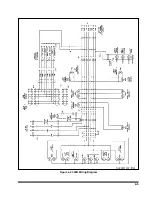

Page 35: ...4 5 Figure 4 2 345B Wiring Diagram ...

Page 36: ...4 6 Figure 4 3 Remote Wiring Diagram ...

Page 41: ...4 11 Figure 4 5 Examples of Camber Figure 4 6 Checking Axle for Bend ...

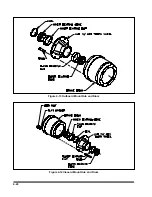

Page 46: ...4 16 Figure 4 10 Axle and Brake Assembly ...

Page 50: ...4 20 Figure 4 13 Outboard Mount Hub and Drum Figure 4 14 Inboard Mount Hub and Drum ...

Page 54: ...4 24 Figure 4 18 Mounting Tires and Wheels Figure 4 19 Stud Tightening Sequence ...

Page 65: ...5 9 NOTES ...