4-4

F-944-1017 Edition

MAINTENANCE AND LUBRICATION

Hitch, Frame, and Deck

Repairing Structural Defects

If any structural defect is found, the fault must be

corrected before further use of the vehicle. To continue

usage could endanger the trailer, its load, personnel,

traffic, and properties. If any cracks or breaks are found,

contact a Landoll authorized service center for repairs.

Wood Deck Care

Inspect the deck weekly for broken or missing planks or

missing attachments. Replace any defective parts

promptly.

Over time, the deck may become damaged from sunlight

and high temperatures. Prevention from weather damage

can be greatly minimized by applying a good water

repellent that contains a UV inhibitor to all visible

surfaces of the decking using a hand held roller, or more

preferred, hand held pump up sprayer.

Acceptable wood weather protection products to use

include Thompson’s and Baer’s Water Seal, boiled

linseed oil, and Penofin and Wood Guard by ISK

Biosciences of Memphis, Tennessee. Best results will be

obtained when applied twice annually - spring and fall.

Hydraulic System

General

1.

Check the oil level of the tractor wet kit or hydraulic

engine power hydraulic tank weekly, or after any

leakage.

for proper hydraulic oil.

Check the hydraulic oil level with hydraulic cylinders

in the retracted position and the hydraulic pump

disengaged.

2.

Overfilling can cause hydraulic fluid overflow during

operation.

3.

Check the lubricating oil level in the engine of the

hydraulic engine power option.

4.

Inspect hydraulic hoses for chafing or damage.

Replace if jacket or braid of hose is damaged.

5.

Replace hydraulic engine power filter as specified in

Electrical System

1.

Maintenance of the electrical system consists of

inspection and minor servicing. Any wire, connection

or electrical component showing signs of corrosion,

wear, breakage or unraveling must be repaired or

replaced.

2.

Frayed or unraveling wire must have the defective

section removed and replaced with wire of the same

color and gauge. Seal all connections and insulate.

3.

Corroded terminals must have the corrosion

removed, source of corrosion neutralized and the

terminals resealed, protected, and insulated.

4.

Fuse or circuit breaker burn-out or blow-out usually

indicates an electrical short-circuit, although a fuse

can occasionally fail from vibration. Insert a second

fuse or reset the breaker. If this fuse immediately

burns out or the breaker trips, locate the cause of the

electrical short and repair.

5.

A light that repeatedly burns-out usually indicates a

loose connection, poor system ground, or a

malfunctioning voltage regulator. Locate the source

of the problem and repair. System grounds must be

grounded to bare metal surfaces. Paint, grease, wax,

and other coatings act as insulators. Replacement

lamps must be equivalent to the factory installed

lamp.

Summary of Contents for 345F

Page 2: ......

Page 6: ......

Page 22: ...3 10 F 944 1017 Edition OPERATING INSTRUCTIONS Figure 3 4 Steps for Loading and Unloading...

Page 30: ...3 18 F 944 1017 Edition OPERATING INSTRUCTIONS Page Intentionally Blank...

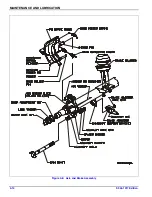

Page 44: ...4 14 F 944 1017 Edition MAINTENANCE AND LUBRICATION Figure 4 8 Axle and Brake Assembly...

Page 61: ......