MAINTENANCE AND LUBRICATION

4-5

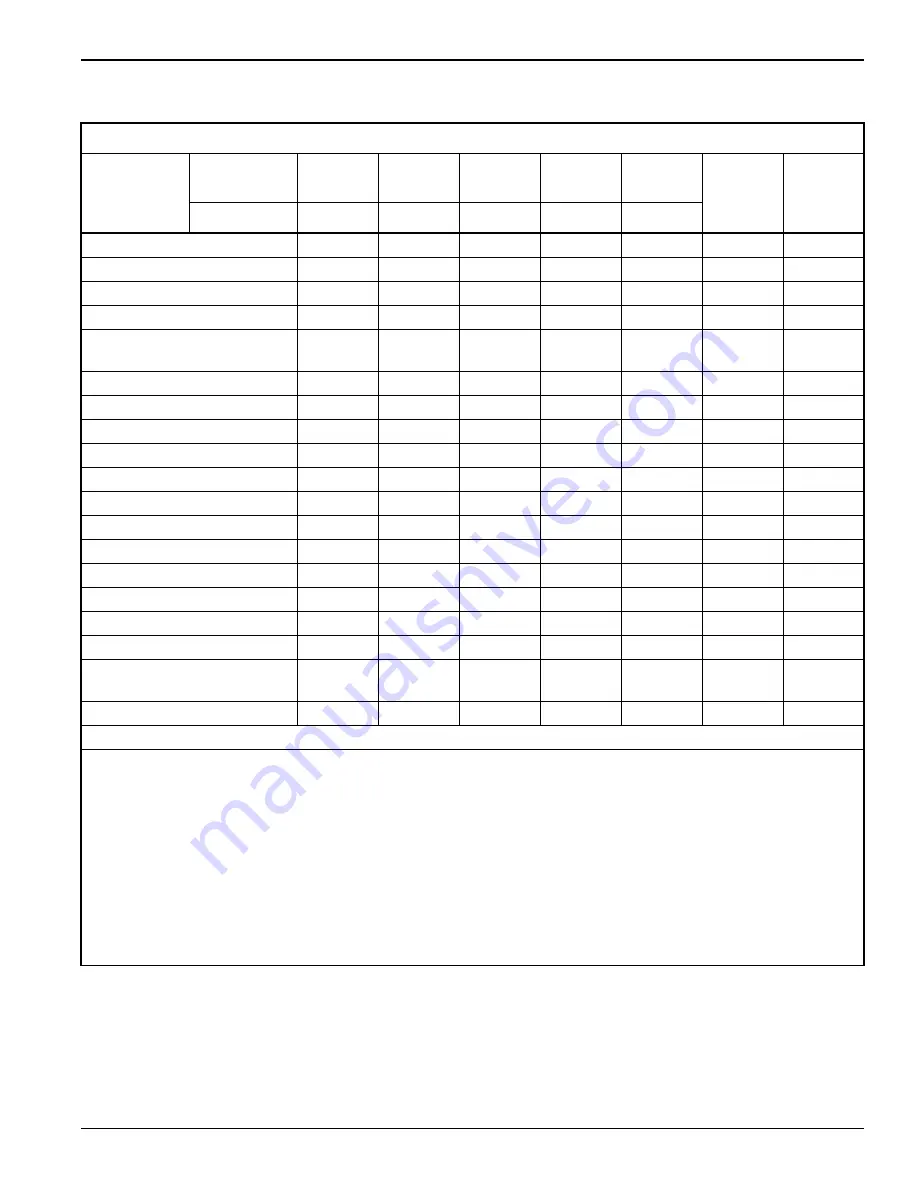

Table 4-2: Maintenance Schedule

NORMAL OPERATING SERVICE INTERVALS

SERVICE

INTERVAL:

TIMES

1st 5

Hours

Weekly

Monthly

6 Months

Yearly

LUBE #

NOTES

MILES

50

500

2,000

12,000

25,000

LIGHTS

I

I

WIRING AND CONNECTIONS I

I

FASTENERS

I, T

I

b

WOOD DECK

I

A

h

PIVOT PIN, LIFT PINS, AND

LOCK PINS

I

I, L

3

WINCH CABLE ASSEMBLIES I

I, L

4

g

BRAKE AIR SYSTEM

I

I

I

ABS VALVES

I, C

BRAKE ADJUST AND WEAR

I

I, T

d

SLACK ADJUSTERS

I

I

L

3

c

CAMSHAFT ASSEMBLIES

I

I

L

3

c

HUB OIL

I

I, L

R

5

c

WHEEL BEARINGS

I

I, T

5

c

TIRE INFLATION AND WEAR

I

I

e

WHEEL LUG NUTS

I, T

I

I, T

f

HYDRAULIC OIL

I

I

R

1

c

HYDRAULIC FILTER

R

R

HOSES

(Inspect & Replace

as needed)

I

I

I,R

WINCH GEAR CASE

I

I

2

c

I - Inspect, R - Replace, T - Tighten/Adjust Torque, L - Lubricate, C - Clean, A - Apply

NOTES:

a.

Perform at the time shown. Shorten service intervals when operating in severe or dirty conditions.

b.

(Torque Specifications) for correct torque.

c.

(Lube Specification Chart) for recommended lubricant.

d.

Call Landoll Customer Services for procedures to replace.

e.

See Serial Number Plate on the front of the trailer for proper inflation requirements.

f.

See Figure 4-15

, Stud Tightening Sequence

g.

Inspect prior to and after each use.

h.

Apply water repellent w/ UV inhibitor

Summary of Contents for 345F

Page 2: ......

Page 6: ......

Page 22: ...3 10 F 944 1017 Edition OPERATING INSTRUCTIONS Figure 3 4 Steps for Loading and Unloading...

Page 30: ...3 18 F 944 1017 Edition OPERATING INSTRUCTIONS Page Intentionally Blank...

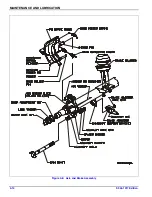

Page 44: ...4 14 F 944 1017 Edition MAINTENANCE AND LUBRICATION Figure 4 8 Axle and Brake Assembly...

Page 61: ......