OPERATING INSTRUCTIONS

3-21

CAUTION

7.

When the engine starts, release the key. Gradually

push the choke lever in until the engine runs

smoothly.

IMPORTANT

Black smoke from the exhaust and a rough engine

indicate overchoking.

8.

To adjust the speed, turn the throttle control in or out,

as needed, until the engine runs smoothly at a speed

capable of withstanding use of the hydraulic controls.

The hydraulic controls should now be functional.

9.

Before shutting it off, allow the engine to cool down

by running at a slow idle for thirty seconds.

10. Once the engine is cool, turn or push the throttle

completely in and turn the ignition switch key to the

OFF position.

Air Ride Operation

1.

Trailer air pressure must be maintained above 90 PSI

before operating. PROTECTION VALVES are used to

maintain 65 PSI air brake pressure during

suspension or remote system air loss.

2.

The Models 425/440 tandem axle semitrailer is

equipped with a ride control valve located on front

axle. When moving the undercarriage from transport

to load position, the front axle is raised off ground,

causing suspension air bags to deflate achieving low

load angle.

CAUTION

3.

The Model 455 triple axle semitrailer, with 10’-1”

spread between front and rear axles is equipped with

additional height control valves to adjust the

suspension during loading and unloading operations.

When moving the undercarriage from transport to

load position, the undercarriage is tilted with the

center axle air bags inflated and rear axle

suspension air bags deflated to achieve low load

angle. This function positions the center axle for

added undercarriage support to the semitrailer and

payload when tilted for loading/unloading.

CAUTION

4.

Different tractor fifth wheel heights may affect proper

operation of the triple axle suspension air system. In

the event front and rear axle suspension air bags are

not inflated or feel soft by the time the undercarriage

has reached transport position, adjustment to the

front and rear axle control valve linkage may be

required

(See “Triple Axle Air Ride Height

Adjustment for Transport” on page 4-13.)

Do not crank engine for more than 10 seconds. If

engine does not start, consult the owner’s

manual supplied with the engine.

If suspension air loss should occur, completely

deflate suspension and temporarily operate on

the air springs internal rubber bumpers. Carefully

proceed to the nearest semitrailer service facility.

To deflate the air suspension, disconnect the

lower connection on the linkage of the automatic

air valves. Rotate the valve control arms down

about 45

o

to exhaust the air. To restore to normal

operation, simply reverse the procedure.

Insure suspension air bags are inflated on all

axles when moving undercarriage from load to

transport position. Failure to do so can cause

excessive tire wear.

Summary of Contents for 425B Series

Page 2: ......

Page 6: ...iv F 543 1011 Edition...

Page 14: ...2 6 F 543 1011 Edition STANDARD SPECIFICATIONS...

Page 26: ...3 12 F 543 1011 Edition OPERATING INSTRUCTIONS Figure 3 7 Steps for Loading and Unloading...

Page 32: ...3 18 F 543 1011 Edition OPERATING INSTRUCTIONS Figure 3 12 Dock Leveler Operation...

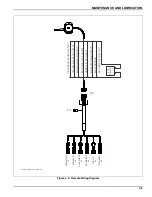

Page 61: ...MAINTENANCE AND LUBRICATION 4 21 Figure 4 13 Axle and Brake Assembly...

Page 76: ...4 36 F 543 1011 Edition MAINTENANCE AND LUBRICATION Page Intentionally Blank...

Page 86: ...5 10 F 543 1011 Edition TROUBLESHOOTING GUIDE...

Page 87: ......