MAINTENANCE AND LUBRICATION

4-13

6.

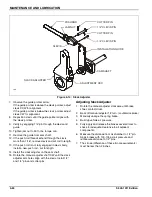

Loosen the 1/4” adjusting lock nut located on the

adjusting block, allowing the control arm to move

approximately 1 inch. Move the adjusting block until

holes align, then insert locating pin.

7.

Align the control arm linkage to the control arm lower

bracket and re-tighten the 1/4” adjusting lock nut to

2-4 ft. lbs. The ride height valve should now be

correctly adjusted.

8.

Remove the locating pin.

9.

The block can now be removed by using the height

control valve as an improvised jack by disconnecting

the control arm at the lower bracket and pushing the

control arm to an “up” position.

10. Remove the block and reconnect the linkage. This

allows the Automatic Height Control Valve to resume

normal operation.

11. Check the air ride height. If necessary, go through

the adjustment procedure again until the proper air

ride height is achieved.

12. Check the air ride height periodically and adjust as

needed.

Triple Axle Air Ride Height

Adjustment for Transport

1.

Before adjusting, the vehicle must be empty with the

kingpin at operating height and have air supplied to

the trailer.

2.

Disconnect linkage at all three control arms and raise

the center axle control arm to the “up” position,

raising the trailer until a spacer block (3” for 12-1/4

brake) (5” for 16-1/2 brake) can be placed between

axle tube and undercarriage frame.

3.

Lower the trailer by exhausting air from the air

springs by moving the control arm to the “down”

position (about 45

o

) until the axle tube is resting on

the block.

4.

Return the control arms slowly to the center position,

then insert wood locating pins into the adjusting block

and bracket on the height control valves. Loosen the

1/4” adjusting lock nuts located on the adjusting

blocks. This will allow the control arms to oscillate

approximately 1”. Reconnect the linkages. Torque to

24-48 inch lbs.

5.

Retighten the 1/4” adjusting lock nuts at the adjusting

blocks to 24-48 in. lbs.

6.

Remove the locating pin.

7.

The block can now be removed by using the height

control valve as an improvised jack by disconnecting

the control arm at the lower bracket and pushing the

control arm to an “up” position.

8.

Move control arms to “down” position, completely

exhausting system. Then reconnect lower linkages

and torque to 24-48 in. lbs. The suspension system

will return to and maintain the proper ride height.

Triple Axle Height Control Adjustment

for Loading

1.

Pull undercarriage out of pockets 18”, dump air, and

tilt trailer up.

2.

Disconnect center axle height control linkage and

dowel pin control arm not to move. Put block between

top of axle and frame, 3-1/2” set ride height.

3.

Disconnect front and rear axle height control linkages

at lower brackets. Move control arms to the center

position. Inserting wood locating pins into the

adjusting block and bracket on height control valves.

4.

On the front axle,

loosen the 1/4” adjustment lock

nuts located on the adjusting block. Connect linkage

to top hole of lower bracket for proper adjustment.

On

the rear axle,

loosen the 1/4” adjustment lock nuts

located on the adjusting block. Connect linkage to

bottom hole of lower bracket for proper adjustment.

5.

Retighten the 1/4” adjusting locknuts at front and rear

adjusting blocks to 24-48 in. lbs.

6.

Disconnect front and rear axle linkages from lower

brackets and remove the wood locating pins.

7.

On the front axle,

reconnect linkage to bottom hole

of lower bracket for normal operation. Torque to

24-48 in. lbs.

On the rear axle,

reconnect linkage to

top hole of lower bracket for normal operation. Torque

to 24-48 in. lbs.

8.

Return undercarriage to transport position.

9.

Remove wood locating pin from center axle height

control valve and spacer block between axle and

frame. Reattach linkage to bottom hole of lower

bracket. Torque to 24-48 in. lbs.

CAUTION

Insure suspension air cylinders are inflated on all

axles. Failure to do so can cause excessive tire

wear.

Summary of Contents for 425B Series

Page 2: ......

Page 6: ...iv F 543 1011 Edition...

Page 14: ...2 6 F 543 1011 Edition STANDARD SPECIFICATIONS...

Page 26: ...3 12 F 543 1011 Edition OPERATING INSTRUCTIONS Figure 3 7 Steps for Loading and Unloading...

Page 32: ...3 18 F 543 1011 Edition OPERATING INSTRUCTIONS Figure 3 12 Dock Leveler Operation...

Page 61: ...MAINTENANCE AND LUBRICATION 4 21 Figure 4 13 Axle and Brake Assembly...

Page 76: ...4 36 F 543 1011 Edition MAINTENANCE AND LUBRICATION Page Intentionally Blank...

Page 86: ...5 10 F 543 1011 Edition TROUBLESHOOTING GUIDE...

Page 87: ......