4-22

F-543-1011 Edition

MAINTENANCE AND LUBRICATION

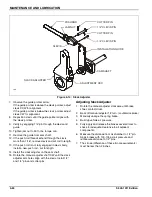

Reassembly for 12-1/4” X 7-1/2” Brakes

1.

Install new camshaft bushing and seals into the

spider.

IMPORTANT

When installing camshaft seals, the seal on the slack

adjuster side is installed facing into spider. This

allows grease to purge outside the brake assembly

when greasing the camshaft bushing.

2.

Install cam roller assemblies onto the brake shoes.

3.

Install “D” shaped camshaft washer onto the

camshaft.

4.

Install the camshaft into the spider. Install spacer

washer and lock ring retainer on camshaft before

sliding the camshaft through the camshaft support

bracket. Install the slack adjuster, washer and lock

ring retainer.

5.

Install shoes, anchor pin bushings, anchor pins, and

spacers onto spider. Install anchor lock rings.

IMPORTANT

Always use all new springs when servicing brakes.

6.

Install brake return spring.

7.

Connect slack adjuster to brake chamber pushrod.

8.

Adjust automatic slack adjuster as outlined in

“Adjusting Slack Adjuster” on page 4-24.

Disassembly for 16-1/2” x 7" Brakes

1.

Release brakes and back off slack adjuster

2.

Remove slack adjuster lock ring and slack adjuster.

3.

Remove drum assembly

4.

Disengage the roller retainers from the rollers.

5.

Press down on the bottom brake shoe and remove

the lower cam roller. Lift the top shoe and take out

the top cam roller.

6.

Lift out the shoe retractor spring, which is now free of

tension.

7.

Swing the lower shoe back approximately 180

o

to

relieve the tension on the shoe keeper springs.

Remove the springs and slip the shoes off the anchor

pins.

8.

Remove camshaft lock ring, spacer washer(s) and

camshaft.

9.

After removing the shoes, completely inspect all

brake components, servicing as necessary.

Reassembly for 16-1/2 x 7" Brakes

1.

Install new anchor pin bushings, camshaft bushing

and camshaft seals into the spider.

IMPORTANT

When installing camshaft seals, the seal on the slack

adjuster side is facing into spider. This allows grease

to purge outside the brake assembly when greasing

the camshaft bushing.

2.

Install cam roller, retainer clip and retractor spring

retainers onto the camshaft.

3.

Install 1/8” thick camshaft washer onto the camshaft.

4.

Install the camshaft into the spider. Install spacer

washer and lock ring retainer on camshaft before

sliding the camshaft through the camshaft support

bracket. Install the slack adjuster, washer and lock

ring retainer.

5.

Install the brake keeper onto the shoes. Install shoes

onto the spider by placing shoes in place on the

anchor pins, then “wrap” the two shoes into place

about the spider.

6.

Install the shoe retractor spring onto the shoes.

7.

Connect slack adjuster to brake chamber pushrod.

8.

Adjust automatic slack adjuster as outlined in

Summary of Contents for 425B Series

Page 2: ......

Page 6: ...iv F 543 1011 Edition...

Page 14: ...2 6 F 543 1011 Edition STANDARD SPECIFICATIONS...

Page 26: ...3 12 F 543 1011 Edition OPERATING INSTRUCTIONS Figure 3 7 Steps for Loading and Unloading...

Page 32: ...3 18 F 543 1011 Edition OPERATING INSTRUCTIONS Figure 3 12 Dock Leveler Operation...

Page 61: ...MAINTENANCE AND LUBRICATION 4 21 Figure 4 13 Axle and Brake Assembly...

Page 76: ...4 36 F 543 1011 Edition MAINTENANCE AND LUBRICATION Page Intentionally Blank...

Page 86: ...5 10 F 543 1011 Edition TROUBLESHOOTING GUIDE...

Page 87: ......