TROUBLESHOOTING GUIDE

5-5

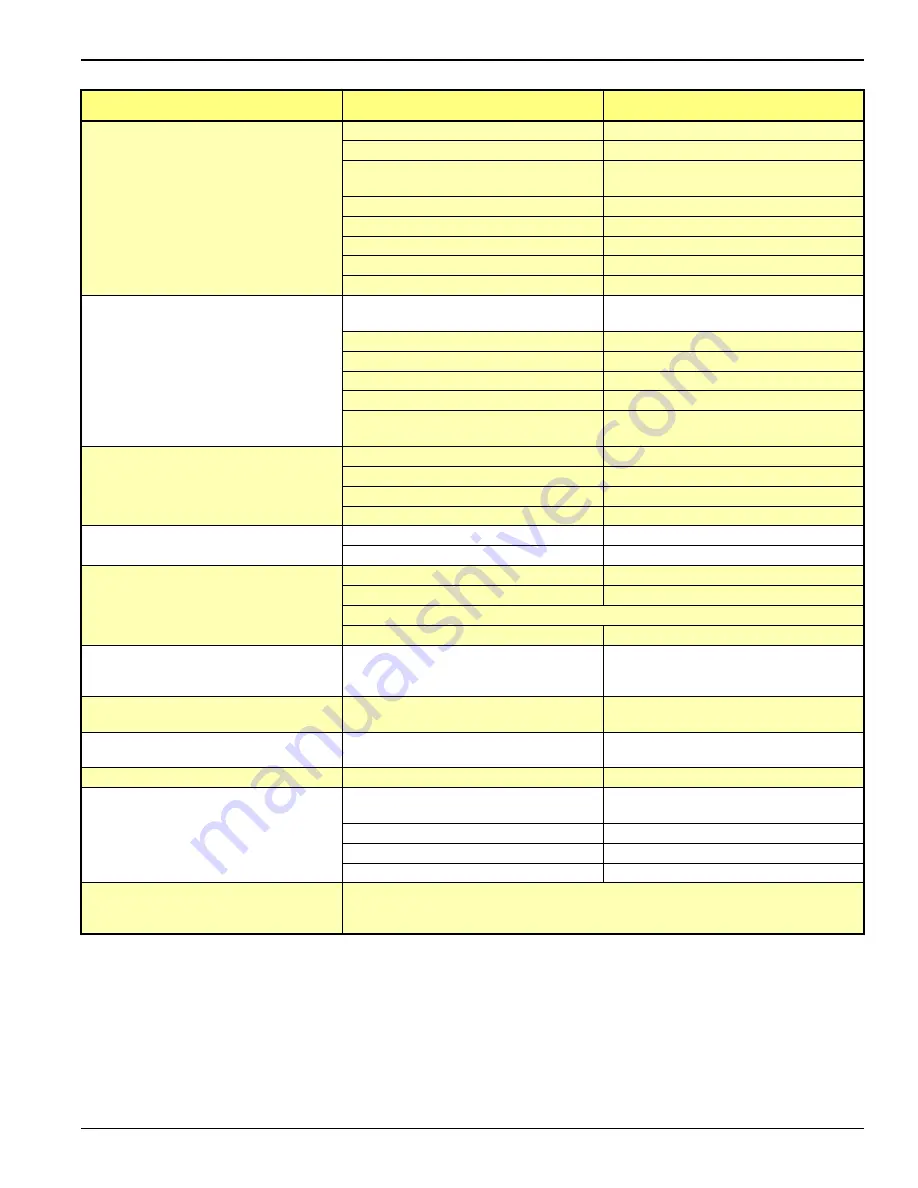

ALL BRAKES DO NOT RELEASE

Air system improperly connected to tractor

Tighten or adjust connections.

Brake valve on tractor is applied

Release brake

Relay emergency valve in emergency

position

Check line pressure and check valve

Restricted tubing or line

Locate restriction and remove

Defective tractor protection valve

Troubleshoot tractor air system.

Parking brakes locked

Troubleshoot air system

Moisture in air system

Check air system

Tractor pressure too low

Adjust to provide 105 psi min.

INSUFFICIENT BRAKES

Brakes need adjusting

Adjust brakes

Brakes need lubricating

Lubricate brakes

Brakes need relining

Reline brakes

Low air pressure

Troubleshoot air system.

Defective relay emergency valve

Repair or replace.

Brakes overheated

Stop and allow brakes to cool, locate

cause of overheating.

BRAKES GRABBING

Grease on brake linings

Reline brakes

Brake rigging binding

Align brakes or replace bent parts.

Defective brake valve on tractor

Repair or replace valve.

Defective relay emergency valve

Repair or replace valve.

EXCESSIVE LEAKAGE WITH BRAKES

RELEASED

Relay emergency valve leaking

Repair or replace valve

Leaking tubing or hose

Replace defective part.

EXCESSIVE LEAKAGE WITH BRAKES

APPLIED

Relay emergency valve leaking

Repair or replace valve.

Leaking brake chamber diaphragm

Replace diaphragm.

Call Factory or see qualified Trailer/Brake Technician

Leaking tubing or hose

Replace defective part.

EXCESSIVE LEAKAGE WITH

EMERGENCY SYSTEM ONLY APPLIED -

NO LEAKAGE WITH NORMAL BRAKING

Defective relay emergency valve

Repair or replace valve.

EXCESSIVE WATER PRESENT IN

BRAKE SYSTEM

Reservoir not drained often enough

Drain reservoir daily.

EXCESSIVE OIL PRESENT IN BRAKE

SYSTEM

Compressor on tractor passing excessive

oil

Repair compressor.

BRAKE WILL NOT APPLY PROPERLY

Flat spot on cam roller or camshaft

Replace and lubricate.

BRAKES WILL NOT APPLY WHEN

EMERGENCY LINE IS DISCONNECTED

Initial air pressure too low

Allow air system to build up to

minimum 90 PSI and stabilize.

Defective relay valve

Repair or replace valve.

Air line leak

Locate leak and repair.

Brake chamber leak

Locate leak and repair or replace.

ABS WARNING LIGHT STAYS

ON

Refer to Rockwell WABCO ABS maintenance manual supplied with semitrailer, for

system function and use of blink code diagnostics.

PROBLEM

PROBABLE CAUSE

SOLUTION

Summary of Contents for 425B Series

Page 2: ......

Page 6: ...iv F 543 1011 Edition...

Page 14: ...2 6 F 543 1011 Edition STANDARD SPECIFICATIONS...

Page 26: ...3 12 F 543 1011 Edition OPERATING INSTRUCTIONS Figure 3 7 Steps for Loading and Unloading...

Page 32: ...3 18 F 543 1011 Edition OPERATING INSTRUCTIONS Figure 3 12 Dock Leveler Operation...

Page 61: ...MAINTENANCE AND LUBRICATION 4 21 Figure 4 13 Axle and Brake Assembly...

Page 76: ...4 36 F 543 1011 Edition MAINTENANCE AND LUBRICATION Page Intentionally Blank...

Page 86: ...5 10 F 543 1011 Edition TROUBLESHOOTING GUIDE...

Page 87: ......