MAINTENANCE AND LUBRICATION

4-29

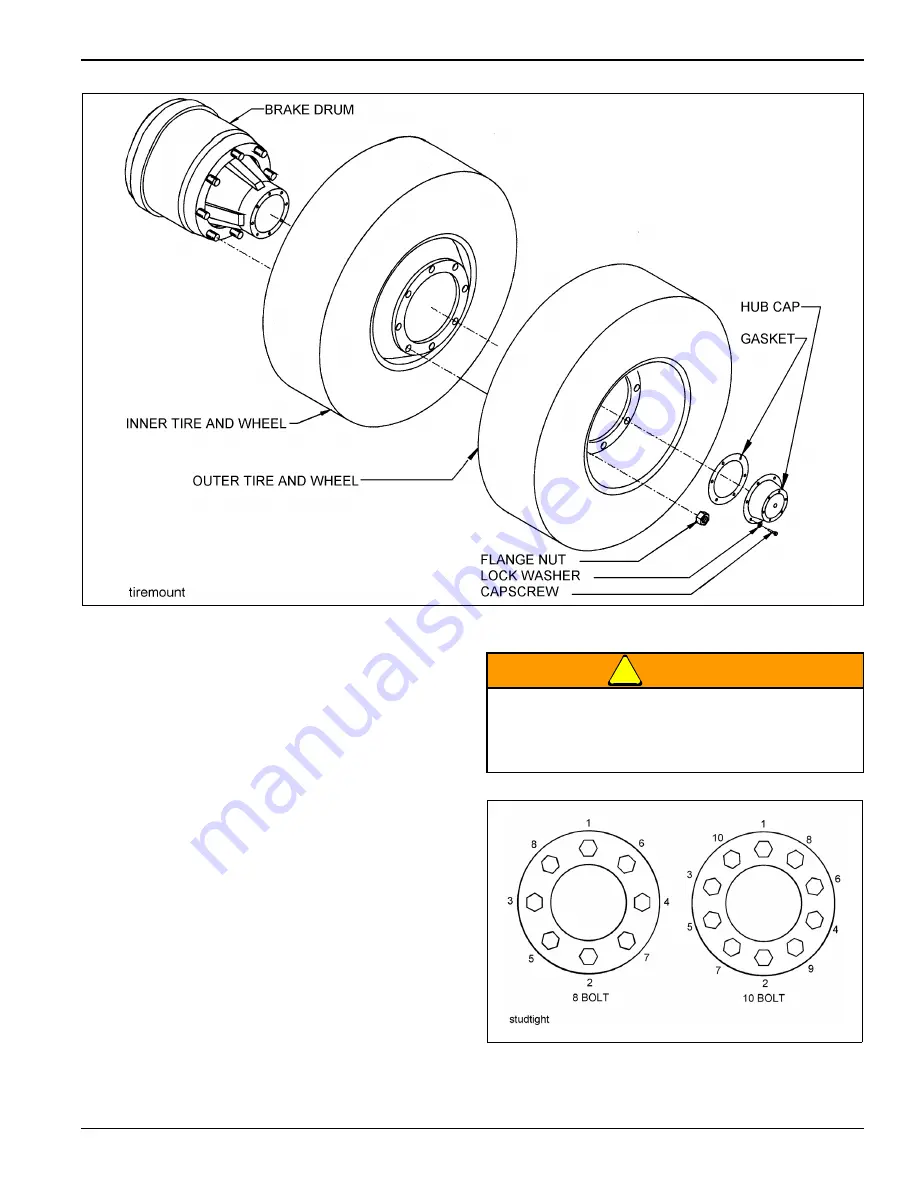

Figure 4-19: Mounting Tires and Wheels

Mounting Tire and Wheel

1.

Make sure that all mounting surfaces are clean and

free of rust, dirt or paint. A wire brush may be used to

clean these surfaces

2.

Position the inner disc wheel over the studs, being

careful not to damage the stud threads. Make sure

that the disc wheel is flat against the mounting

surface and that there is clearance between the disc

wheel taper and brake drum.

3.

Position the outer disc wheel being careful not to

damage the threads. Be sure the valve stems for

both the inner and outer tire are accessible.

4.

Install the flange nut and tighten to 50 foot-pounds

using the sequence in

Then tighten to

full torque of

450

to 5

0

0 foot-pounds.

5.

Torque will drop after the first 50 to 100 miles of

operation. Check the nuts for proper torque after this

interval and retighten them.

WARNING

Figure 4-20: Stud Tightening Sequence

Use a torque wrench to assure proper torque.

Insufficient torque can cause stud breakage and

damage wheel pilots. Overtorque can overstress

the studs and strip the threads.

Summary of Contents for 425B Series

Page 2: ......

Page 6: ...iv F 543 1011 Edition...

Page 14: ...2 6 F 543 1011 Edition STANDARD SPECIFICATIONS...

Page 26: ...3 12 F 543 1011 Edition OPERATING INSTRUCTIONS Figure 3 7 Steps for Loading and Unloading...

Page 32: ...3 18 F 543 1011 Edition OPERATING INSTRUCTIONS Figure 3 12 Dock Leveler Operation...

Page 61: ...MAINTENANCE AND LUBRICATION 4 21 Figure 4 13 Axle and Brake Assembly...

Page 76: ...4 36 F 543 1011 Edition MAINTENANCE AND LUBRICATION Page Intentionally Blank...

Page 86: ...5 10 F 543 1011 Edition TROUBLESHOOTING GUIDE...

Page 87: ......