c.

The

20,000 lb and 30,000 lb PNEUMATIC

WINCH CONTROL

has two positions.

RELEASE

In this position, the winch is disen-

gaged and air tension (if present) is

released from the cable. Allow up to

15 seconds for release of air tension.

The cable can then “free-wheel”. The

cable may need to be slackened to

allow winch to disengage.

IMPORTANT

WHEN REELING WINCH, MOMENTARILY RO-

TATE REEL IN OPPOSITE DIRECTION TO RE-

LIEVE TENSION ON WINCH GEARS. THIS WILL

AID IN WINCH RELEASE.

TENSION

In this position, the winch is engaged

and cable can be “power” spooled in

or out. The winch is now controlled

by the Winch Hydraulic Lever. Winch

air tensioner will also be engaged, if

present.

d.

The

20,000 lb WINCH AIR TENSION

or

pressure on the cable is controlled by an air

pressure regulator located behind the main

control panel. It is set at 60 psi but can be ad-

justed, if desired, for more or less tension.

1.

To adjust, turn the regulator adjusting

knob. Clockwise rotation increases and

counterclockwise rotation decreases outlet

pressure and tension.

2.

When reducing from a higher to a lower

setting, first reduce to some pressure less

than that desired, then bring up to the

desired point.

3.

Push lockring on adjusting knob downward

to lock pressure setting. To release, push

lockring upward. Free spool tension is

applied by adjustable spring load on the

cable. Free spool tension can be adjusted,

if desired, for more or less free spool

tension.

e.

The

30,000 lb WINCH AIR TENSION

or

pressure on the cable is controlled at system

air pressure for operation. An air pressure

regulator located behind the main control

panel is used to reduce air pressure and ca-

ble tension during free spool. It is set at 60

psi, but can be adjusted, if desired, for more

or less free spool tension. For adjustment

procedure,

see Section 3-16.2d. 1. through

f.

Once the winch is selected, winch operation

is the same as described in

Section 3-16.1.

IMPORTANT

REMOTE

CONTROL

OPERATION

IS

DE-

SCRIBED IN SECTION 3-21.

3-17 DOCK LEVELER CONTROL OPERATION (OPTION)

DANGER

WHEN USING DOCK LEVELERS, THE

SEMITRAILER MUST BE KEPT LEVEL

AT ALL TIMES. DO NOT LOWER THE

PARKING STANDS. LOADS BEING

PLACED ON THE SEMITRAILER MUST

BE KEPT CENTERED ON THE SEMI-

TRAILER. AN UNLEVEL SEMITRAILER

MAY ALLOW A LOAD TO SLIDE, CAUS-

ING INJURY OR DEATH TO ANYONE

NEAR THE LOAD!

DANGER

1. DO NOT OPERATE DOCK LEVEL-

ERS WITH UNDERCARRIAGE OUT OF

REAR POCKETS.

2. DO NOT OPERATE DOCK LEVEL-

ERS WITH INSUFFICIENT SPACE ON

BOTH SIDES OF THE SEMITRAILER.

SEMITRAILER WILL LEAN TOWARD

THE SIDE WITH THE SHORTEST CYL-

INDER. PERSONS OR EQUIPMENT

CAN BE CRUSHED BETWEEN SEMI-

TRAILER SIDE AND RIGID OBJECTS.

3. TRACTOR PARK BRAKES MUST BE

SET WHEN USING DOCK LEVELERS.

3-19

Summary of Contents for 600B Series

Page 8: ......

Page 12: ......

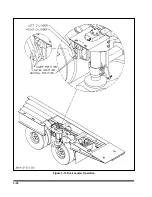

Page 14: ...3 2 Figure 3 1 Front Trailer Terminology Figure 3 2 Rear Trailer Terminology...

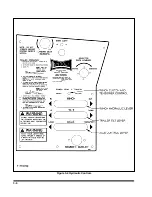

Page 18: ...3 6 Figure 3 4 Hydraulic Controls...

Page 26: ...3 14 Figure 3 7 Steps for Loading and Unloading...

Page 32: ...3 20 Figure 3 10 Dock Leveler Operation...

Page 38: ...3 26 Figure 3 14 Rear Impact Guard and Antilock Brake System...

Page 42: ...4 2 Figure 4 1 Lubrication Points...

Page 48: ...4 8 Figure 4 3 600B Wiring Diagram...

Page 49: ...4 9 Figure 4 4 Remote Wiring Diagram...

Page 52: ...4 12 Figure 4 5 Tandem Axle Air Ride Suspension System Figure 4 6 Air Ride Height Adjustment...

Page 54: ...4 14 Figure 4 7 Triple Axle Air Ride Suspension System...

Page 57: ...4 17 Figure 4 9 Checking Axle Alignment Figure 4 10 Examples of Camber...

Page 61: ...4 21 Figure 4 13 Axle and Brake Assembly...

Page 71: ...4 31 Figure 4 21 Dock Leveler Leg Assembly...

Page 73: ...4 33 Figure 4 22 Crank Landing Gear Assembly...

Page 84: ...NOTES 5 10...