i.

Lift out polyethylene bushing.

j.

Remove thrust bearing, thrust washer, and

woodruff key from screw in assembly.

k.

Replace all worn, bent, or broken parts.

4-14.4

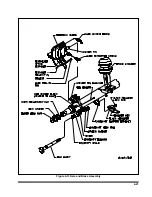

Leg Assembly

a.

Place thrust washer on top of elevating

screw. Thrust bearing follows and must be as-

sembled with cup of bearing up.

b.

Place outer leg over screw and nut portion

of inner leg assembly. Press down until

threaded part of elevating screw is clearly

visible through hole in top of the outer leg.

c.

Fit polyethylene bushing into place around

screw in leg assembly and push all the way

down into bearing block.

d.

Install woodruff key in slot of elevating

screw and install bevel gear in place.

e.

Secure bevel gear. Use Loc-tite on threads

of screw and install jam lock nut. Make sure

bevel gear turns freely.

f.

Place bevel pinion gear on top of bevel gear

on the opposite side from mounting bracket of

single speed out leg, or mounting bracket side

of 2-speed outer leg.

g.

Install shaft through outer. Install shims re-

moved previously and slide shaft through

shims and bevel pinion gear.

h.

Align holes in bevel pinion gear with hole in

shaft, insert groove pin so that shafts turn

freely and the two gears are engaged prop-

erly.

i.

Check for proper shimming. Proper shim-

ming achieved when the shafts turn freely

and there is no more than 1/16" gap between

the shims and the outer leg when shaft is

pushed toward the bevel gear.

j.

Make sure this assembly is well lubricated

with a permanent type lubricant (1/2 pound,

minimum).

k.

Replace gasket, metal cover, and self tap-

ping screws.

l.

Install landing gear back on trailer. Adjust

both legs to the same length and install cross

shaft and bolts and nuts. When installing

cross shaft make sure there is enough end

play and gears crank freely.

4-14.5

Gearbox Assembly

a.

To replace shifter gear, install pin in shaft.

Then slide shifter on shaft so that recess in

shifter gear fits over pin. Install spiral pin.

b.

Insert shaft with gear in lower hole of gear-

box and install shifter spring in place.

c.

Slide gear on shaft and insert shaft in mid-

dle hole of gear box.

d.

Install step gear on shaft and secure with

spiral pins.

e.

Place idler gear in shaft with shoulder of

gear to inside.

f.

Gears must be coated with permanent type

grease in order to obtain successful opera-

tion.

g.

Replace gasket and gearbox cover and as-

semble with bolts and nuts.

4-34

Summary of Contents for 600B Series

Page 8: ......

Page 12: ......

Page 14: ...3 2 Figure 3 1 Front Trailer Terminology Figure 3 2 Rear Trailer Terminology...

Page 18: ...3 6 Figure 3 4 Hydraulic Controls...

Page 26: ...3 14 Figure 3 7 Steps for Loading and Unloading...

Page 32: ...3 20 Figure 3 10 Dock Leveler Operation...

Page 38: ...3 26 Figure 3 14 Rear Impact Guard and Antilock Brake System...

Page 42: ...4 2 Figure 4 1 Lubrication Points...

Page 48: ...4 8 Figure 4 3 600B Wiring Diagram...

Page 49: ...4 9 Figure 4 4 Remote Wiring Diagram...

Page 52: ...4 12 Figure 4 5 Tandem Axle Air Ride Suspension System Figure 4 6 Air Ride Height Adjustment...

Page 54: ...4 14 Figure 4 7 Triple Axle Air Ride Suspension System...

Page 57: ...4 17 Figure 4 9 Checking Axle Alignment Figure 4 10 Examples of Camber...

Page 61: ...4 21 Figure 4 13 Axle and Brake Assembly...

Page 71: ...4 31 Figure 4 21 Dock Leveler Leg Assembly...

Page 73: ...4 33 Figure 4 22 Crank Landing Gear Assembly...

Page 84: ...NOTES 5 10...