4-4

F-733-1114

OPERATION AND MAINTENANCE

2.

The hydraulic system is not filled with oil and should

be purged of air before transporting and field

operations. Carefully hitch the disc to the tractor and

connect the hydraulic lift hoses. Check to make sure

the tractor hydraulic reservoir is full of the

manufacturer’s recommended oil. Slowly raise the

machine, and continue to hold the hydraulic lever

until all lift cylinders are fully extended. Lower and

raise the unit to verify that all cylinders are working

simultaneously throughout the stroke. If the cylinders

are not working evenly or together, fully extend the lift

cylinders and continue to hold the lever to purge any

remaining air. Do not loosen any hoses or fittings.

Recheck tractor reservoir to make sure it is within

operating limits.

3.

Always fully extend the cylinders and hold the lever to

ensure the cylinders are rephased before starting

any field operation. This will keep all cylinders in time

and frame sections level when operating.

4.

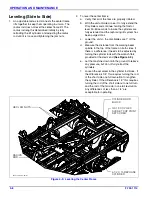

The transport locks for the hydraulic lift system are

plumbed into the fold system. During folding they are

activated to lock the machine up in the fully raised

position, while unfolding the locks are released

permitting the machine to be lowered.

NOTE

If performing service or repair work, activate the fold to

engage the transport locks, or lower the machine down to

the ground and relieve hydraulic pressure.

Figure 4-3: Installed Transport Locks

Figure 4-4: Stored Transport Locks

6250-transport-extended

3-1/4 X 8 HYDRAULIC

CYLINDER

TRANSPORT

LOCK

3-1/2 X 8 HYDRAULIC

CYLINDER

6250-transport-lock-retracted

3-1/4 X 8 HYDRAULIC

CYLINDER

TRANSPORT

LOCK

3-1/2 X 8 HYDRAULIC

CYLINDER

Summary of Contents for 6250

Page 2: ......

Page 13: ...STANDARD SPECIFICATIONS 2 5 Table provided for general use NOTES...

Page 21: ...STANDARD SPECIFICATIONS 2 13 Table provided for general use NOTES...

Page 28: ...Page Intentionally Blank...

Page 90: ...NOTES...