3

OPERATION AND MAINTENANCE

3-1

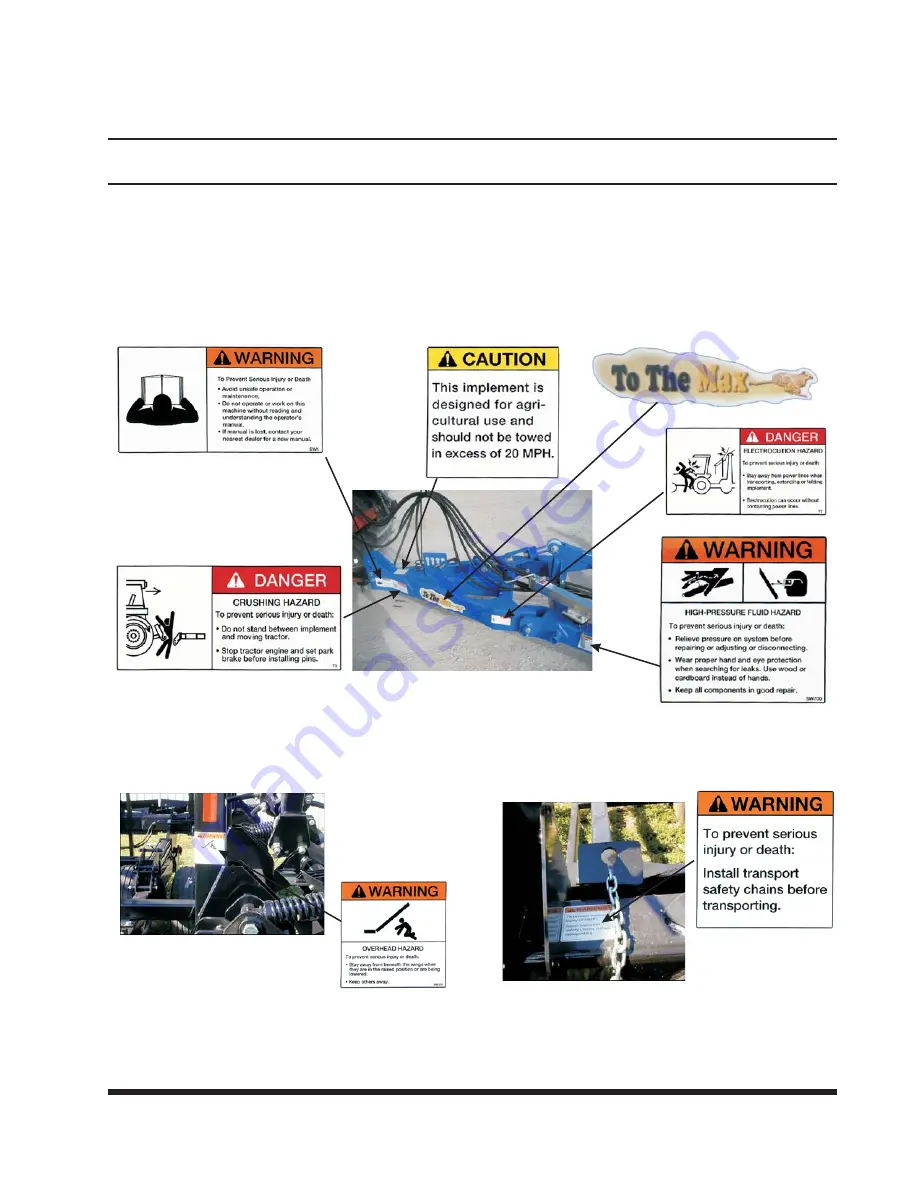

SAFETY INFORMATION AND DECAL LOCATIONS

The types of Safety/Information Signs and lo-

cations on the harrow are shown in

Figures 3-1,

3-2, and 3-3

. Good safety practice requires that

you familiarize yourself with the various Safety/In-

formation Signs. Replacement part numbers are

found in the Parts List manual. Immediately replace

all worn, damaged, peeling, or obscured decals.

3-1

hitch frame decals

Figure 3-1 Hitch Frame Decals

side wing decals

Figure 3-2 Side Wing Decals

wing frame decals

Figure 3-3 Wing Frame Decals

Summary of Contents for 7130 TO THE MAX

Page 2: ......

Page 4: ...NOTES ii...

Page 8: ...NOTES 1 2...

Page 12: ......

Page 33: ...NOTES 3 21...

Page 34: ......

Page 37: ...NOTES 4 3...

Page 38: ......