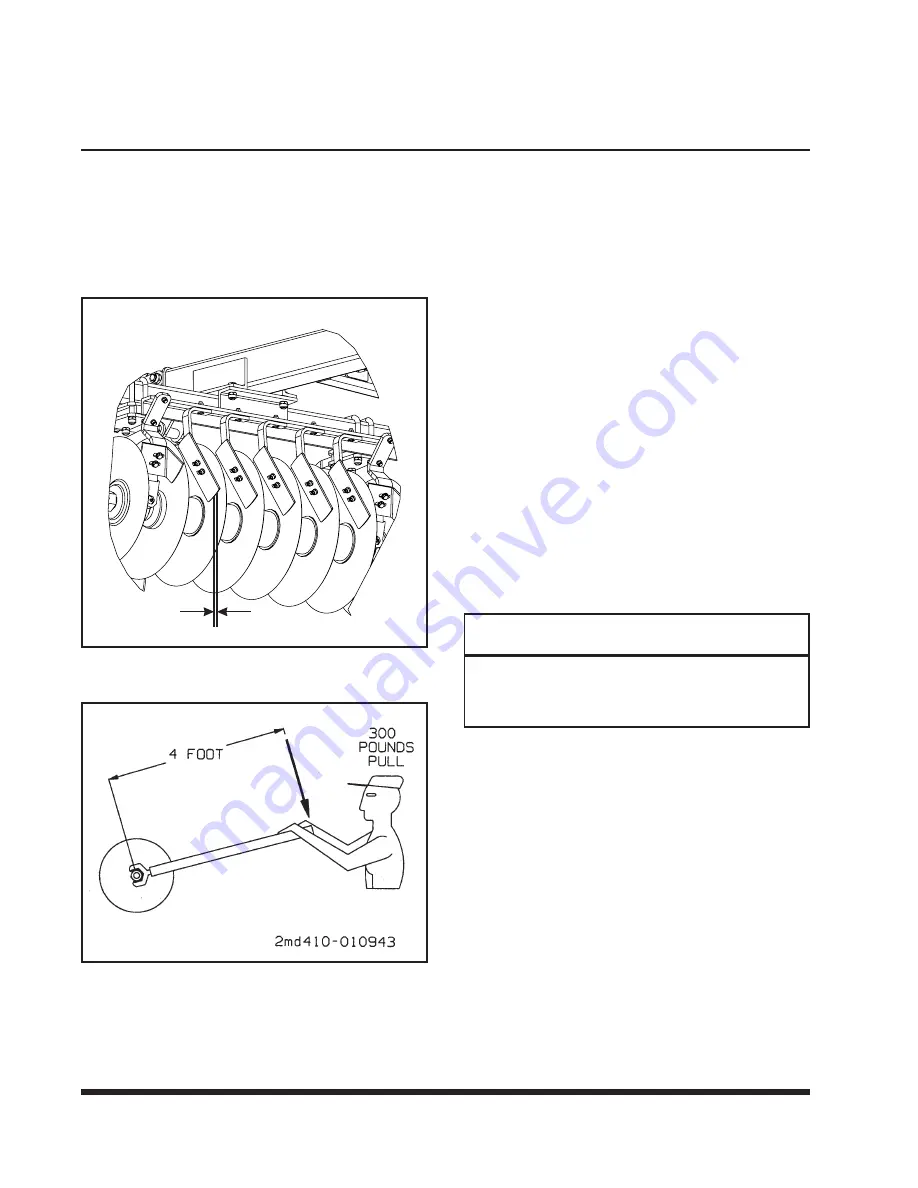

4-12 SCRAPER ADJUSTMENT

The Vertical Harrow is equipped with rigid

scrapers at regular spools with dual scrapers at the

disc bearings.

4-12.1

Rigid scrapers should be set initially as

close to the disc blade as possible without

rubbing (approximately 1/8")

(See Figure

4-13).

A slotted hole at the top of each

scraper is provided for individual adjustment.

Adjustments may be made for entire gangs,

by loosening the u-bolts around the an-

gle-iron scraper bars and sliding the whole

bar. Scraper arms are made of spring steel.

In wet conditions, the scraper may be set

against the disc blade and will function as a

spring-loaded scraper.

4-12.2

Scraper blades have two positions and

are reversible. The blades are initially set in

the front position to position scraper closer to

the spool. This position will perform better in

wet and heavier residue conditions. The

blade may be moved back for dryer condi-

tions and climates where less scraper action

is needed.

4-12.3

Dual scrapers are provided at the bear-

ing locations to scrape the disc blade and to

limit the amount of soil and residue carried

into the bearing hanger. Scrapers can be in-

dividually adjusted in or out from the concave

side of the disc blade.

CAUTION

TIGHTEN ALL 1-3/4" NUTS TO 1,250

FOOT-POUNDS OF TORQUE (SEE FIG-

URE 4-14.

4-12

1/8”

7430 scraper adj

Figure 4-13 Scraper Adjustment

Figure 4-14 1,250 Foot-Pounds of Torque

Summary of Contents for 7430 Series

Page 3: ...MODEL 7430 VERTICAL HARROW OPERATOR S MANUAL PURCHASED FROM DATE ADDRESS PHONE NO SERIAL NO i...

Page 4: ...NOTES ii...

Page 8: ...NOTES 1 2...

Page 16: ......

Page 44: ...NOTES 3 28...

Page 65: ...NOTES 4 21...

Page 66: ......

Page 70: ...NOTES 5 4...