3-11 SWINGOUT OUTRIGGER PLATFORM EXTENSION SET-UP

DANGER

DO NOT OPERATE IF ANY EXTENSION

IS NOT LOCKED IN PLACE. INSPECT

ALL EXTENSIONS TO INSURE EACH IS

LOCKED SECURELY IN POSITION.

3-11.1

Use extension brackets to increase the

platform width to support wide loads.

3-11.2

Lift up and rotate swing-out outriggers

outward

(See Figure 3-5)

.

3-11.3

Place extension planks on outriggers.

WARNING

1. TOP OF EXTENSION PLANKS MUST

BE FLUSH WITH MAIN DECK BOARDS.

2. CENTERLINE OF TRACKS OR TIRES

MUST BE LOADED ON THE MAIN

DECK, NOT ON EXTENSION BRACK-

ETS.

FAILURE TO LOAD EXTENSION

BRACKETS PROPERLY CAN RESULT

IN EQUIPMENT DAMAGE AND PER-

SONAL INJURY.

3-11.4

Center the load on the trailer. DO NOT

load to one side. Position the load for proper

weight distribution. See

Section 3-12

for

loading procedure.

WARNING

1. DO NOT OVERLOAD EXTENSIONS.

OVERWIDTH RATINGS ARE GIVEN IN

STANDARD SPECIFICATIONS.

2. DO NOT SECURE LOAD TO OVER-

WIDTHS OR UNDERCARRIAGE. SE-

CURE LOAD FRAME TO MOUNTED D-

RINGS OR GOTCHAS LOCATED IN

THE APPROACH PLATE AND FRAME

BEAM FLANGES. FAILURE TO DO SO

MAY CAUSE SERIOUS INJURY OR

DEATH.

3-11

Summary of Contents for 825A

Page 8: ......

Page 12: ......

Page 14: ...3 2 Figure 3 1 Model 825 Trailer Terminology Figure 3 2 Service Hookups...

Page 18: ...3 6 Figure 3 3 Hydraulic Controls...

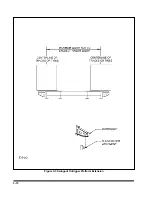

Page 22: ...3 10 Figure 3 5 Swingout Outrigger Platform Extension...

Page 24: ...3 12 Figure 3 6 Gooseneck Attachment to Frame...

Page 34: ......

Page 36: ...4 2 Figure 4 1 Lubrication Points...

Page 40: ...4 6 Figure 4 2 Model 825A Wiring Diagram...

Page 43: ...4 9 Figure 4 4 Tandem Axle Air Ride Suspension System...

Page 44: ...4 10 Figure 4 5 Tandem Axle W Flip Air Ride Suspension System...

Page 47: ...4 13 Figure 4 8 Checking Axle Alignment Figure 4 9 Examples of Camber...

Page 52: ...4 18 Figure 4 12 Axle and Brake Assembly...

Page 59: ...4 25 Figure 4 18 Mounting Tires and Wheels Figure 4 19 Stud Tightening Sequence...

Page 69: ...NOTES 5 9...

Page 70: ......