3-18.2

The

WINCH CLUTCH HANDLE (See

is located on the right or

curb-side end of the winch assembly. The

function of the

WINCH CLUTCH HANDLE

is

to engage or disengage the winch, allowing it

to respond to the

WINCH HYDRAULIC

LEVER

. For trailers equipped with optional

PNEUMATIC WINCH CONTROL

(20,000

lb.), the control is a switch on the control

panel

(See Figure 3-3)

. If the semitrailer also

has the optional

WINCH AIR TENSIONER

, it

also is controlled by the same switch on the

control panel. For the 20,000 lb. winch, this

switch controls both the clutch and the winch

air tensioner simultaneously. For the 12,000

lb. winch, this switch controls only the air

tensioner.

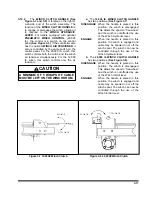

CAUTION

A MINIMUM OF 5 WRAPS OF CABLE

MUST BE LEFT ON THE WINCH DRUM.

a.

The

12,000 lb. WINCH CLUTCH HANDLE

has two positions:

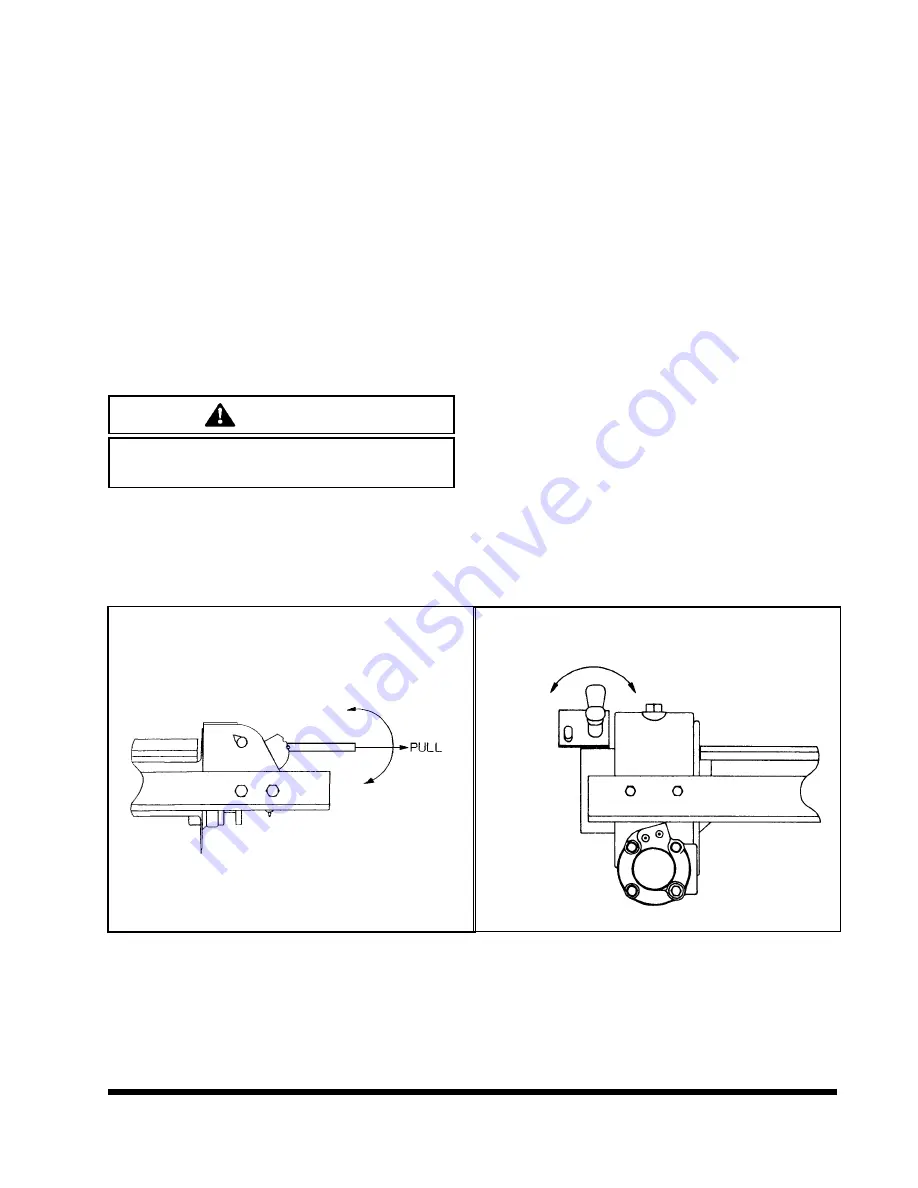

(See Figure 3-7)

DISENGAGE

When the handle is placed is this

position, the winch is disengaged.

This allows the spool to “free-wheel”

and the winch is not affected by use

of the Winch Hydraulic lever.

ENGAGE

When the handle is placed in this

position, the winch is engaged and

cable may be spooled on or off the

winch spool. The winch can now be

controlled through the use of the

Winch Hydraulic lever.

b.

The

20,000 lb WINCH CLUTCH HANDLE

has two positions.

(See Figure 3-8).

DISENGAGE

When the handle is placed in this

position, the winch is disengaged.

This allows the spool to “free-wheel”

and the winch is not affected by use

of the Winch In/Out lever.

ENGAGE

When the handle is placed in this

position, the winch is engaged and

cable may be spooled on or off the

winch spool. The winch can now be

controlled through the use of the

Winch In/Out lever.

3-17

Figure 3-7 12,000# Winch Clutch

DISENGAGE

ENGAGE

Figure 3-8 20,000# Winch Clutch

ENGAGE

DISENGAGE

Summary of Contents for 825A

Page 8: ......

Page 12: ......

Page 14: ...3 2 Figure 3 1 Model 825 Trailer Terminology Figure 3 2 Service Hookups...

Page 18: ...3 6 Figure 3 3 Hydraulic Controls...

Page 22: ...3 10 Figure 3 5 Swingout Outrigger Platform Extension...

Page 24: ...3 12 Figure 3 6 Gooseneck Attachment to Frame...

Page 34: ......

Page 36: ...4 2 Figure 4 1 Lubrication Points...

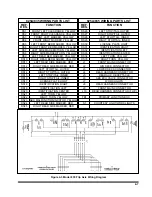

Page 40: ...4 6 Figure 4 2 Model 825A Wiring Diagram...

Page 43: ...4 9 Figure 4 4 Tandem Axle Air Ride Suspension System...

Page 44: ...4 10 Figure 4 5 Tandem Axle W Flip Air Ride Suspension System...

Page 47: ...4 13 Figure 4 8 Checking Axle Alignment Figure 4 9 Examples of Camber...

Page 52: ...4 18 Figure 4 12 Axle and Brake Assembly...

Page 59: ...4 25 Figure 4 18 Mounting Tires and Wheels Figure 4 19 Stud Tightening Sequence...

Page 69: ...NOTES 5 9...

Page 70: ......