3-15 PREPARATION FOR TRANSPORT

3-15.1

After securing the load, following the

steps as outlined in

Section 3-14,

back the

tractor until the gooseneck is within a few

inches of the front of the semitrailer.

3-15.2

Using the

TRAILER LIFT

lever, to lower

or raise the gooseneck, as necessary, until

the load hooks are aligned with the receiver

hooks.

3-15.3

Slowly back the gooseneck into the

semitrailer until the gooseneck hooks guide

into place.

3-15.4

Using the

TRAILER LIFT

lever, lift the

semitrailer until the semitrailer rests fully on

the load blocks.

3-15.5

Reconnect the electrical and air service

lines from the semitrailer to the gooseneck.

The 7 pole electrical connector attaches to

the receptacle in the side of the gooseneck.

Disconnect dummy gladhands to connect

service and emergency air hoses to their re-

spective gladhand on the side of the goose-

neck.

3-15.6

Using the

TRAILER LIFT

lever, raise

the semitrailer until load carrier locks into

place and enough clearance is obtained to

seat the load blocks.

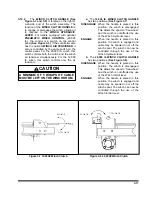

CAUTION

FAILURE TO SUPPORT THE SEMI-

TRAILER FULLY ON THE LOAD

BLOCKS DURING TRANSPORT AND

PARKING MAY RESULT IN DAMAGE

TO THE LOAD, THE SEMITRAILER,

AND POSSIBLE SERIOUS INJURY OR

DEATH TO INDIVIDUALS NEAR THE

SEMITRAILER.

CAUTION

THE GOOSENECK MAY BE USED IN

THE LOWERED OR RAISED POSI-

TIONS TO AVOID LOW CLEARANCE

OBSTACLES OR HIGH CENTERING.

NEVER EXCEED 2 MILES AN HOUR

WHEN TRANSPORTING THE SEMI-

TRAILER IN THIS MANNER.

3-16 UNLOADING THE SEMITRAILER

3-16.1

Prepare to unload the semitrailer by fol-

lowing the steps outlined in

Section 3-12.

3-16.2

Remove the chains and binder or the

tie-straps from the load.

3-16.3

Drive the load off the front of the semi-

trailer or remove a stationary load by means

of a forklift, crane, or other means satisfac-

tory to the constitution of the load.

3-16.4

Reattach the gooseneck to the semi-

trailer following the steps as outlined in

Sec-

tion 3-15.

WARNING

WHEN REMOVING LOAD, INSURE

THAT THE LOAD IS STEERING

STRAIGHT SO IT DOES NOT MANEU-

VER OFF THE SIDE OF THE SEMI-

TRAILER. FAILURE TO SO COULD RE-

SULT IN DAMAGE TO EQUIPMENT, IN-

JURY, OR DEATH.

3-16.5

Shut down hydraulic power system.

3-15

Summary of Contents for 825A

Page 8: ......

Page 12: ......

Page 14: ...3 2 Figure 3 1 Model 825 Trailer Terminology Figure 3 2 Service Hookups...

Page 18: ...3 6 Figure 3 3 Hydraulic Controls...

Page 22: ...3 10 Figure 3 5 Swingout Outrigger Platform Extension...

Page 24: ...3 12 Figure 3 6 Gooseneck Attachment to Frame...

Page 34: ......

Page 36: ...4 2 Figure 4 1 Lubrication Points...

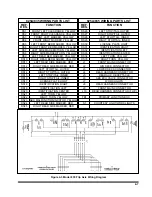

Page 40: ...4 6 Figure 4 2 Model 825A Wiring Diagram...

Page 43: ...4 9 Figure 4 4 Tandem Axle Air Ride Suspension System...

Page 44: ...4 10 Figure 4 5 Tandem Axle W Flip Air Ride Suspension System...

Page 47: ...4 13 Figure 4 8 Checking Axle Alignment Figure 4 9 Examples of Camber...

Page 52: ...4 18 Figure 4 12 Axle and Brake Assembly...

Page 59: ...4 25 Figure 4 18 Mounting Tires and Wheels Figure 4 19 Stud Tightening Sequence...

Page 69: ...NOTES 5 9...

Page 70: ......