4

MAINTENANCE AND LUBRICATION

This section contains instructions necessary for

proper maintenance of the semitrailer. The

825A/835 semitrailer is designed for years of serv-

ice with minimal maintenance. However, proper

maintenance is important for durability and safe

operation and is an owner/user responsibility.

4-1 MAINTENANCE SCHEDULE

Trailer maintenance includes periodic inspec-

tion and lubrication.

Table 4-2, Maintenance

Schedule

, lists the recommended maintenance

and lubrication tasks by time interval and by accu-

mulated mileage (use whichever occurs first).

DANGER

OPERATING THE TRACTOR OR

TRAILER WITH DEFECTIVE, BROKEN

OR MISSING PARTS MAY RESULT IN

SERIOUS INJURY OR DEATH, DAM-

AGE TO THE TRACTOR/TRAILER, ITS

CARGO, OR PROPERTY IN ITS PATH.

4-1.1

Inspection

a.

Inspect the tractor, the trailer, and trailer

parts periodically for damage or signs of

pending failure. Damaged or broken parts

must be repaired or replaced at once. Deter-

mine the cause of any binding or hydraulic

leakage at once. Correct the problem before

using the tractor or trailer.

b.

Use the troubleshooting section,

Chapter 5

to check for “SYMPTOMS” and “PROBLEMS”

of any trailer system not functioning correctly,

or where wear, distortion, or breakage are

found. Administer “REMEDY” according to

the right-hand column of the troubleshooting

section.

4-1.2

Lubrication

detail lubrication

points and intervals, method of application, and lu-

bricant required, and illustrate the location of each

part to be lubricated. During inspections of the

trailer, if lubricants are found to be fouled with dirt

or sand, those parts should be cleaned with paint

thinner, dried, and relubricated immediately. Dirt in

a lubricant forms an abrasive compound that will

wear parts rapidly.

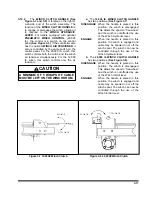

WARNING

PAINT THINNER AND OTHER SOL-

VENTS ARE FLAMMABLE AND TOXIC

TO EYES, THE SKIN, AND RESPIRA-

TORY TRACT. AVOID SKIN AND EYE

CONTACT. GOOD GENERAL VENTILA-

TION IS NORMALLY ADEQUATE. KEEP

AWAY FROM OPEN FLAMES OR

OTHER COMBUSTIBLE ITEMS.

4-1

Summary of Contents for 825A

Page 8: ......

Page 12: ......

Page 14: ...3 2 Figure 3 1 Model 825 Trailer Terminology Figure 3 2 Service Hookups...

Page 18: ...3 6 Figure 3 3 Hydraulic Controls...

Page 22: ...3 10 Figure 3 5 Swingout Outrigger Platform Extension...

Page 24: ...3 12 Figure 3 6 Gooseneck Attachment to Frame...

Page 34: ......

Page 36: ...4 2 Figure 4 1 Lubrication Points...

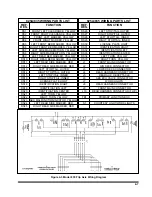

Page 40: ...4 6 Figure 4 2 Model 825A Wiring Diagram...

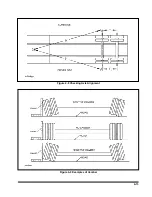

Page 43: ...4 9 Figure 4 4 Tandem Axle Air Ride Suspension System...

Page 44: ...4 10 Figure 4 5 Tandem Axle W Flip Air Ride Suspension System...

Page 47: ...4 13 Figure 4 8 Checking Axle Alignment Figure 4 9 Examples of Camber...

Page 52: ...4 18 Figure 4 12 Axle and Brake Assembly...

Page 59: ...4 25 Figure 4 18 Mounting Tires and Wheels Figure 4 19 Stud Tightening Sequence...

Page 69: ...NOTES 5 9...

Page 70: ......