4-10

F-691-0913 Edition

MAINTENANCE AND LUBRICATION

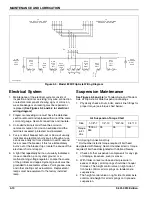

Figure 4-4: Model 835D Flip Axle Wiring Diagram

Electrical System

1.

Maintenance of the electrical system consists of

inspection and minor servicing. Any wire, connection

or electrical component showing signs of corrosion,

wear, breakage or unraveling must be repaired or

replaced.

(See Figures 4-3 and 4-4 for electrical

wiring diagram)

2.

Frayed or unraveling wire must have the defective

section removed and replaced with wire of the same

color and gauge. Seal all connections and insulate.

3.

Corroded terminals must have the corrosion

removed, source of corrosion neutralized and the

terminals resealed, protected, and insulated.

4.

Fuse or circuit breaker burn-out or blow-out usually

indicates an electrical short-circuit, although a fuse

can occasionally fail from vibration. Insert a second

fuse or reset the breaker. If this fuse immediately

burns out or the breaker trips, locate the cause of the

electrical short and repair.

5.

A light that repeatedly burns-out usually indicates a

loose connection, poor system ground, or a

malfunctioning voltage regulator. Locate the source

of the problem and repair. System grounds must be

grounded to bare metal surfaces. Paint, grease, wax,

and other coatings act as insulators. Replacement

lamps must be equivalent to the factory installed

lamp.

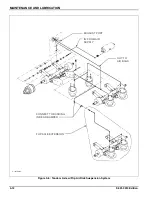

Suspension Maintenance

for Tandem Axle and Tandem

Axle w/ Flip Axle Air Ride Suspension drawings.

1.

Physically check all nuts, bolts, and air line fittings for

proper torque (see torque chart below).

* Air Spring Connections Only.

** First number listed is torque required if bolt head

designated with Neway; Second number listed is torque

required if bolt head designated with Holland Neway.

2.

Check all other suspension components for any sign

of damage, looseness, wear or cracks.

3.

With trailer on level surface and air pressure in

excess of 65 psi, all air springs should be of equal

firmness. The height control valve on right side of

front axle controls all air springs on tandem axle

suspensions.

4.

The height control valve on right side of center axle

controls ride height for all air springs on triple axle

suspension.

DS27

STOP

TAIL

RIGHT

DS35

TURN

RIGHT

DS30

LICENSE

LAMP

DS32

ID

835a flip elec

DS25

MARKER

RIGHT

REAR

DS29

STOP

TAIL

RIGHT

DS24

MARKER

LEFT

REAR

DS33

ID

DS31

ID

DS28

STOP

TAIL

LEFT

DS34

TURN

LEFT

DS26

STOP

TAIL

LEFT

J10

J9

CONNECTS TO MAIN WIRING

HARNESS ON TRAILER

J8

CONNECTS TO BUMPER

HARNESS ON TRAILER

Air Suspension Torque Chart

Size

1-1/8"-7

1/2"-13

*3/4"-16

3/4"-10

Torque

in Ft.

Lbs.

**800 or

550

35

35

150

Summary of Contents for 825D Series

Page 2: ......

Page 6: ...iv F 691 0913 Edition...

Page 14: ...2 6 F 691 0913 Edition STANDARD SPECIFICATIONS...

Page 40: ...3 26 F 691 0913 Edition OPERATING INSTRUCTIONS Page Intentionally Blank...

Page 60: ...4 20 F 691 0913 Edition MAINTENANCE AND LUBRICATION Figure 4 13 Axle and Brake Assembly...

Page 77: ...TROUBLESHOOTING GUIDE 5 9 Notes...

Page 78: ...5 10 F 691 0913 Edition TROUBLESHOOTING GUIDE...

Page 79: ......